China mobile rack for sale mobile pallet racking system supplier

What Is Mobile Pallet Racking

Mobile pallet racking, also known as mobile rack or compact pallet racking, is a high-density storage system that utilizes rolling racks mounted on powered or mechanical carriages. These carriages move along fixed rails embedded in the floor, allowing the aisles between racks to be opened and closed as needed. By eliminating static aisles and compacting the storage footprint, mobile pallet racking maximizes warehouse space utilization while providing convenient access to stored goods. This system is ideal for warehouses with limited space or those seeking to increase storage capacity without expanding their facility.

Advantages of Mobile Pallet Racking

1. Space Optimization: By eliminating fixed aisles and compacting storage space, mobile pallet racking maximizes warehouse capacity, allowing for more efficient use of available floor space.

2. Increased Storage Capacity: Mobile racking can increase storage capacity by up to 120% compared to traditional static racking systems. Mobile pallet racking has a more compact design and higher storage density, allowing more pallets to fit in the same area.

3. Flexibility: Mobile pallet racking systems can be customized to fit specific warehouse layouts and storage requirements, providing flexibility for different types of goods and storage configurations.

4. Suitable for picking: Despite the high-density storage configuration, the mobile pallet racking system allows easy access to pallets in any position, requiring aisles to be opened for access operations.

5. Improved Safety: With features such as aisle entry sensors and safety interlocks, mobile pallet racking systems enhance warehouse safety by preventing accidents and minimizing the risk of damage to goods and equipment.

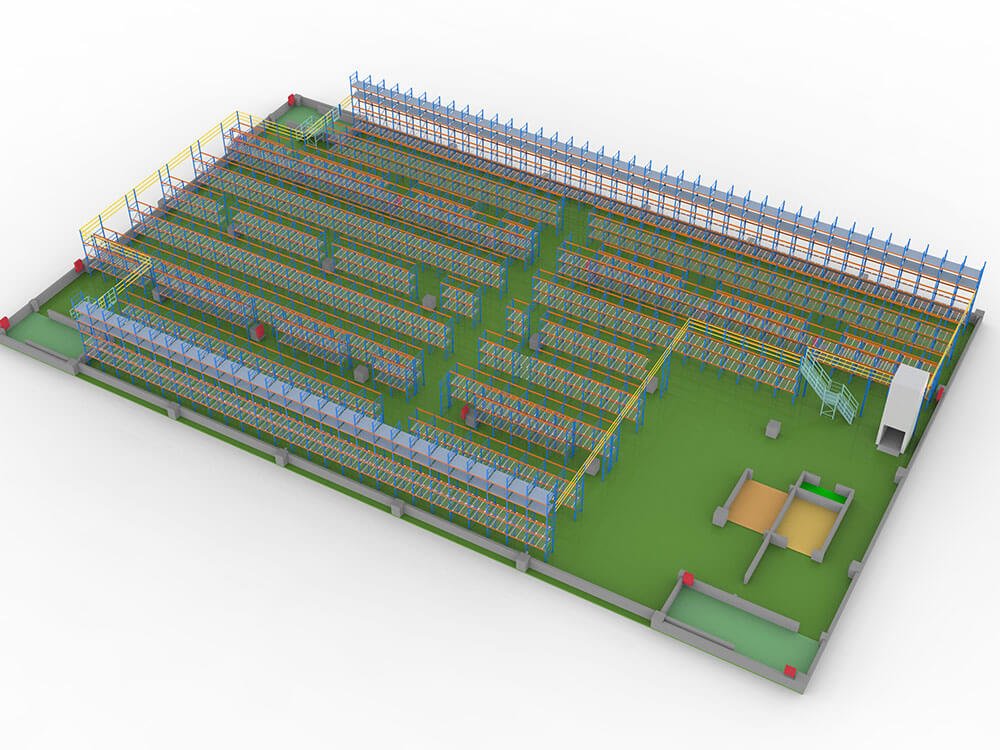

mobile storage rack design

Mobile Storage Rack Layout Design

Please send us detailed data such as warehouse size, cargo size, etc. Our engineers will design a reasonable layout plan for you.

Three-dimensional drawing of mobile racks

The exact dimensions of the racks, the load and the number of tiers will be presented to you in a three-dimensional drawing.

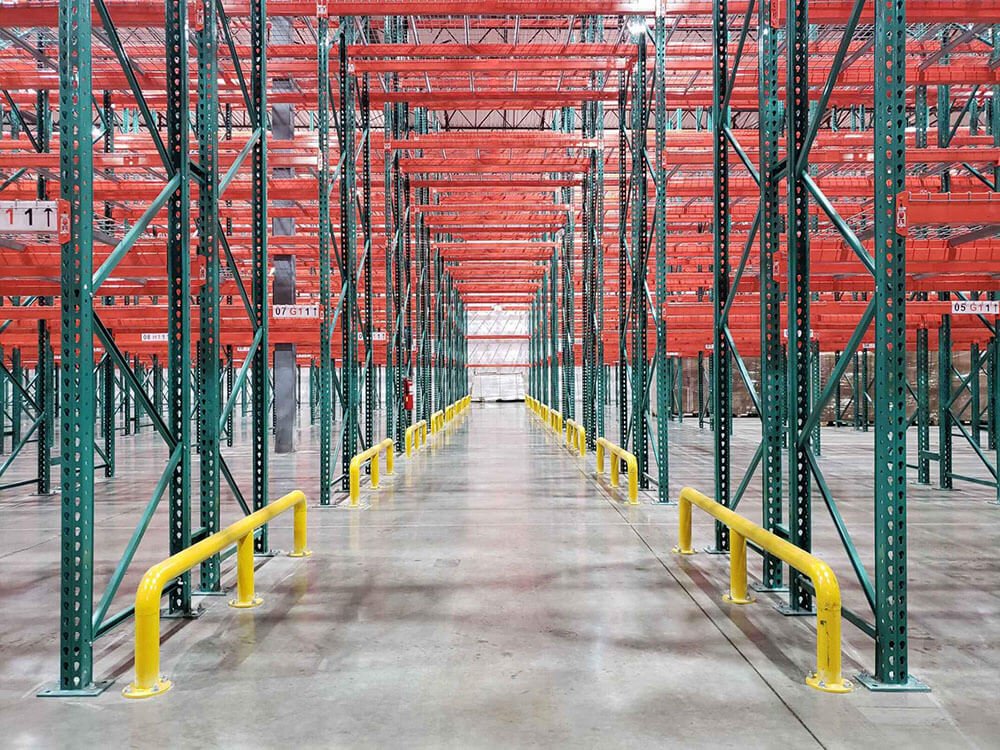

Rendering of Mobile Storage Rack

If the project is complex, we can also produce installation drawings for you, and we can even produce renderings if necessary.

How do mobile pallet racks work?

In mobile racking, the multiple aisles at intervals found in traditional racking systems have been eliminated, leaving only one aisle. Entire rows of racking run on rails mounted on the warehouse floor and can be moved laterally along the rails.

When accessing a specific pallet, the operator activates the system via a control panel or remote device. The electric motor and moving components at the bottom of the rack then begin to operate and the rack moves laterally, creating an aisle at the desired location to access the desired pallet.

Once the pallets have been retrieved or stored, the racks can be moved back together, thereby compressing storage space and maximizing warehouse capacity. This dynamic system ensures efficient use of space while providing access to stored goods when needed.

Application of mobile pallet racking system

Mobile pallet racking for facilities with multiple SKUs

Mobile pallet racking systems are well-suited for facilities with multiple SKUs due to their high storage density and flexibility in organizing pallets. By using mobile bases that can move along rails, these systems allow for compact storage of pallets while still providing easy access to individual SKUs. This is particularly beneficial for facilities with a large variety of products, as it enables efficient organization and retrieval of goods without the need for extensive aisle space. Additionally, mobile pallet racking systems can be equipped with advanced inventory management technology, such as RFID or barcode scanning, to further streamline operations and ensure accurate tracking of inventory across multiple SKUs.

Mobile pallet racking for freezer warehouses

Mobile pallet racking systems can be beneficial for freezer warehouses due to their space-saving design and efficient use of floor space. By utilizing mobile racks, freezer warehouses can maximize their storage capacity while still providing easy access to pallets, even in low-temperature environments. The mobility of the racks allows for flexible aisle configurations, enabling operators to create aisles only where and when needed. This setup minimizes the amount of cold air lost when accessing pallets, helping to maintain stable temperatures within the freezer warehouse. Additionally, mobile pallet racking systems can be equipped with features such as anti-tip mechanisms and durable materials to withstand the harsh conditions of freezer storage.

Mobile pallet racking for high-turnover warehouses

Mobile pallet racking systems are well-suited for high-turnover warehouses due to their dynamic storage capabilities. By using movable bases mounted on rails, these racks can be easily repositioned to provide access to the most frequently accessed pallets. This design minimizes travel time for retrieving goods, facilitating faster picking and replenishment processes. Additionally, mobile pallet racking allows for efficient space utilization by compactly storing pallets while still ensuring accessibility. This flexibility in storage configuration and quick access to inventory make mobile pallet racking an ideal choice for warehouses with high turnover rates.

Frequently Asked Questions About Mobile Pallet Racking System

When should I use mobile racking?

It becomes particularly beneficial in facilities with high-density storage needs, where space utilization is crucial for accommodating a large volume of inventory. Additionally, mobile pallet racking is ideal for warehouses with fluctuating storage requirements or those dealing with fast-moving inventory, as it offers flexibility and adaptability to accommodate changing stock levels. Furthermore, mobile pallet racking is a preferred choice for environments with specialized storage needs, such as freezer warehouses or facilities handling multiple SKUs, where maximizing storage space while ensuring accessibility is paramount.

Are mobile pallet racks costly?

Mobile pallet racks typically involve higher upfront costs compared to traditional selective racking systems due to the added complexity of the mobile bases and motorized mechanisms. However, they offer significant long-term savings by optimizing space utilization and improving inventory accessibility, which can lead to reduced operating expenses and increased efficiency in warehouse operations. Additionally, the return on investment (ROI) for mobile pallet racks can be substantial, especially in warehouses where space is at a premium or where high-density storage is necessary. Therefore, while the initial investment may be higher, the benefits of mobile pallet racks often outweigh the upfront costs in the long run.

Are mobile pallet racks safe?

Yes, mobile pallet racks are designed with safety in mind and are engineered to meet stringent safety standards. They incorporate features such as safety locks, anti-derailment systems, and sensors to ensure safe operation. Additionally, mobile pallet racks undergo rigorous testing and inspection processes to verify their structural integrity and functionality. Proper installation, regular maintenance, and adherence to safety guidelines are essential to ensure the continued safety and reliability of mobile pallet racks in warehouse environments.

Do I need a specialized forklift for mobile pallet racking?

Not required. You can use any kind of forklift truck, including counterbalanced forklifts and reach forklifts, where aisle width and lifting height allow. It is important to specify the type of forklift to be used when designing the mobile pallet racking system so that the aisle width of the racking meets the turning radius of the forklift. When designing your mobile pallet racking, speak carefully with your supplier to ensure the efficient and safe operation of your mobile racking.

What is the speed at which the racks move when the mobile pallet rack is working?

The speed at which mobile pallet racking can move varies depending on factors such as system design, type of moving equipment (e.g. motorized wheels or rails) and safety considerations. In general, mobile pallet racking tracks are designed to move at 3 to 4 meters per minute. Movement speeds are often optimized to increase efficiency while maintaining stability and accuracy during operation.

How wide are the aisles of the mobile pallet rack?

The width of aisles for mobile pallet racking varies depending on factors such as the type of forklift used, storage requirements and warehouse layout, but is most dependent on the type of forklift, as sufficient clearance needs to be provided for the forklift to maneuver safely within the aisle. Generally, aisle widths for mobile pallet racking range from 3 to 6 meters.