China Heavy Duty Cantilever Racking System Manufacturer

What Is Cantilever Racking System

A cantilever racking system is a warehouse storage racking system used for storing long and bulky items such as lumber, pipes and sheet metal. It consists of uprights, cantilevers, bases and cable-stayed designed to support the weight of the stored goods. The uprights are vertical pillars that provide support for the cantilevers. The cantilever extends horizontally out of the column, making it easy to store goods onto the cantilever. According to the different types, cantilever racking is divided into single-sided cantilever racking and double-sided cantilever racking; according to the different load-bearing capacity, cantilever racking can be divided into light cantilever racking and heavy-duty cantilever racking.

Customizable Cantilever Racking for Sale

Typically, cantilever racking is customized due to the fact that different customers have different warehouse sizes and storage needs. Based on our experience in manufacturing cantilever racking, we have listed the following sizes and load capacities of cantilever racking for your reference.

| Size(mm) | Color | Layer | Load Capacity |

|---|---|---|---|

| L2000*D1500*H3000 | Orange | 4 layer | 500kg/arm |

| L3000*D1500*H3000 | Blue | 5 layer | 1500kg/layer |

| L5000*D1500*H3000 | Black | 6 layer | 1500kg/layer |

| Customizable | Customizable | Customizable | Customizable |

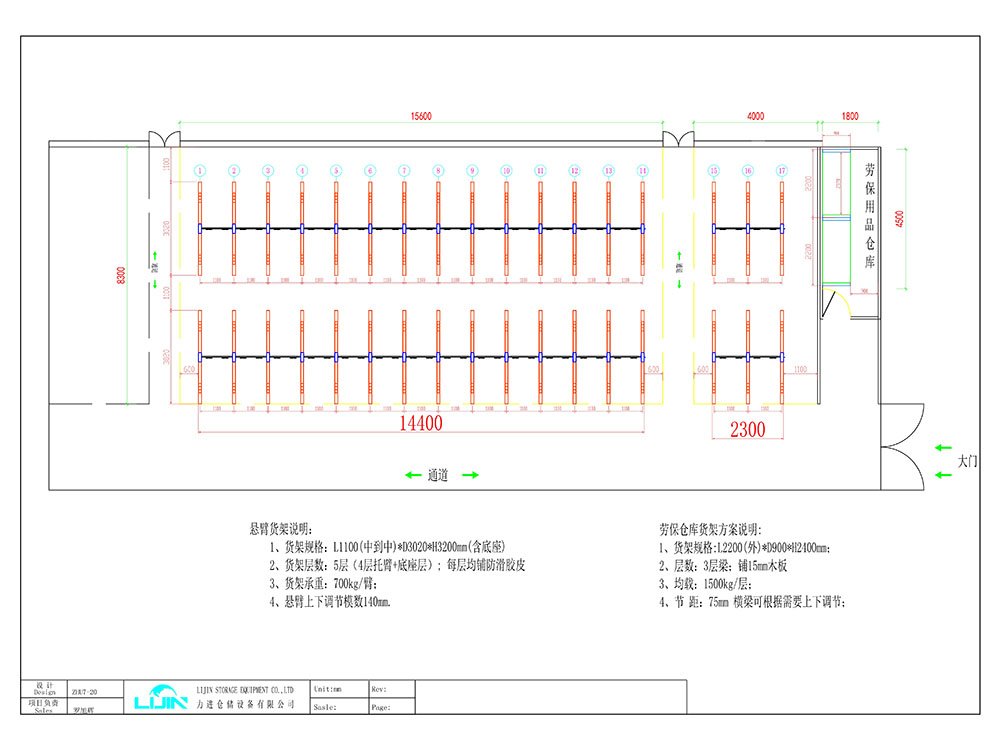

Cantilever rack system design

Cantilever Racking Layout Design

Please send us detailed data such as warehouse size, cargo size, etc. Our engineers will design a reasonable layout plan for you.

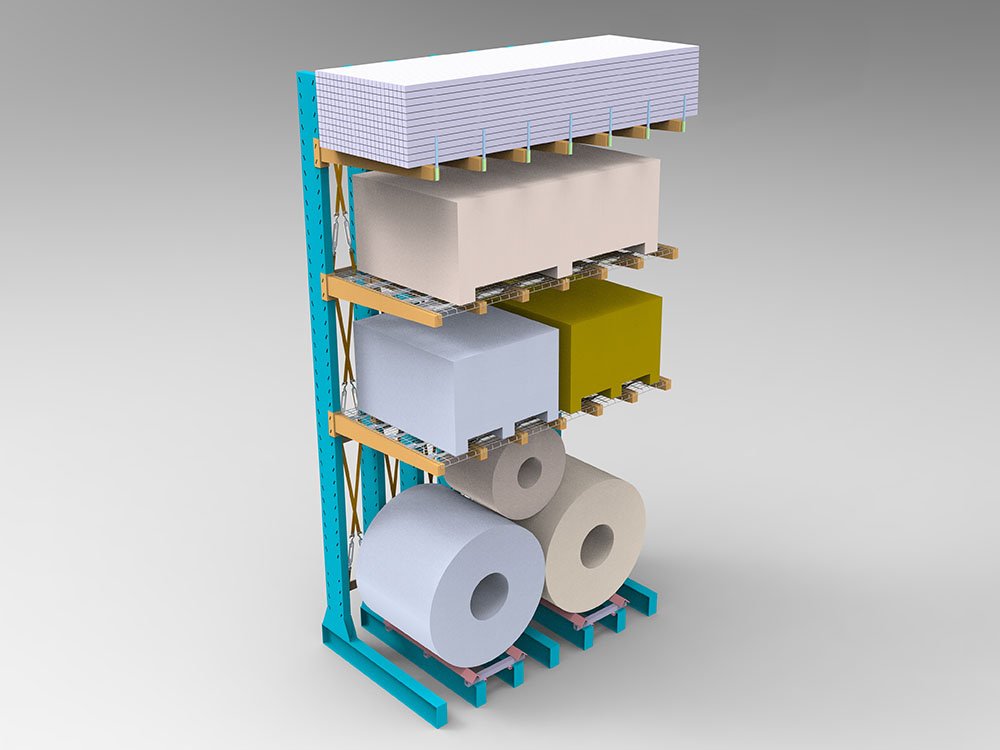

Three-dimensional drawing of cantilever racking

The exact dimensions of the racks, the load and the number of tiers will be presented to you in a three-dimensional drawing.

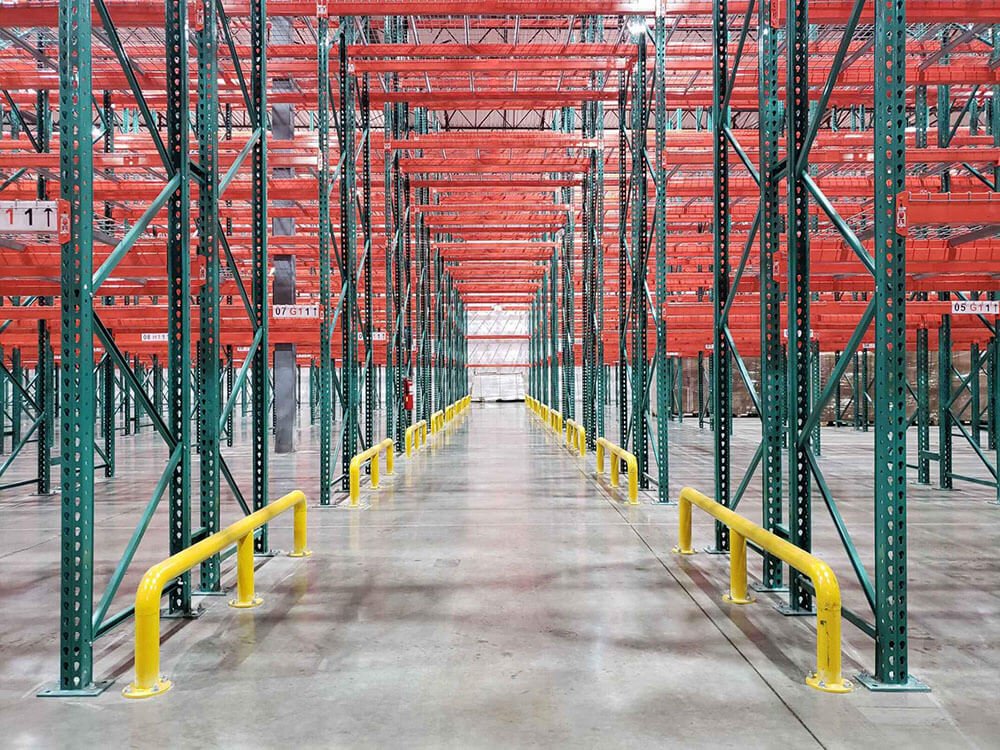

Rendering of Cantilever Racking

If the project is complex, we can also produce installation drawings for you, and we can even produce renderings if necessary.

Why Choose Lracking Custom Cantilever Racking Systems

Lracking, as a leading cantilever racking manufacturer in China, has been producing and selling cantilever racking for more than 16 years. We can provide customized cantilever racking system solutions to meet the storage needs of companies with irregular goods and improve the utilization of their warehouses. Our cantilever racking products have passed ISO9001, CE, TUV, and AS4084 certifications for load capacity and reliable quality. Moreover, China is a vast country with abundant labor resources, so sourcing cantilever racking from China can save you money.

Application of Cantilever Racking

Cantilever Pipe Storage Rack

Cantilever racking is an efficient solution for pipe storage. The flexibility of the cantilever racking design facilitates the loading and unloading of pipes, which is critical in industrial environments. The space created between the arms also allows for easy access to the pipes, making inventory management simpler and more efficient.

Cantilever Car Storage Rack

Cantilever racks are a popular and effective solution for storing cars in a safe and organized manner. Cantilever racking systems are designed for easy access to cars without taking up additional space. If you are looking for an efficient and reliable way to store your car, cantilever racks are a great option.

Cantilever Lumber Racking

Cantilever racking systems are ideal for companies that need to store large quantities of lumber, the open design of the racking system allows for easy access to stored lumber, and the sturdy construction ensures that the racking system can withstand the weight of the lumber. Using cantilever lumber racking to store lumber is an excellent way to organize and maximize storage space while keeping the lumber safe and secure.

Frequently Asked Questions About Cantilever Racking

Does cantilever racking need to be placed against a wall?

No, cantilevered shelving does not always need to be placed against a wall; it can also be freestanding. In some cases, cantilevered shelving is placed against a wall because the wall can provide additional anchoring, which prevents the shelves from tipping over. But don’t worry, cantilever racking manufacturers will design cantilever racking to fit your storage needs, and collapses without severe overloading will generally not happen.

What are the standard dimensions of cantilever racking?

Cantilever racking is usually customized to meet the actual storage needs of a business and there are no standard sizes. In Lracking’s close to two decades of experience in manufacturing cantilever racking, the most common dimensions for cantilever racking are L5000*D1500*H3000mm. when selecting the size of cantilever racking, it is important to take into consideration the weight and volume of the products to be stored.

How much does cantilever racking cost?

The cost of cantilever racking systems can vary greatly depending on several factors, including the size of the racking system, load capacity, and design specifications. On average, single-sided cantilever racking with a capacity of 500kg per arm costs between $300-600. Double-sided cantilever shelving with the same capacity costs between $600 and $1,000. Heavy-duty cantilever shelving with a capacity of 1000-2000 kg per arm is priced between $800 and $2000 per unit.

Is cantilever racking easy to install?

Cantilever racking is relatively simple to install compared to drive-in racking or shuttle racking systems. This is mainly due to the simple structure of cantilever racking, which consists of four main components: base, upright, cantilever and cable-stayed. For larger projects or more complex configurations, it may be necessary to hire a professional installation team for installation.

What is the load capacity of cantilever racking?

The load capacity of each arm of cantilever racking is 500-2000kg, depending on the size and thickness of the cantilever racking material. When designing cantilever racking, you should confirm the load capacity information with the manufacturer. Cantilever racking manufacturers usually label the load capacity information of the cantilever racking system, which should be followed carefully to ensure safe and effective storage of goods.

What are the different types of cantilever racks?

There are various types of cantilever racking to suit different storage needs. Two common types of cantilever racking are single-sided cantilever racking and double-sided cantilever racking. The cantilever of single-sided cantilever rack is located on one side of the upright, while the cantilever of double-sided cantilever rack is located on both sides of the upright. According to the load-bearing capacity can be divided into light cantilevered racking, medium cantilevered racking and heavy cantilevered racking.