Warehouse Stackable Racks Portable Stacking Racking System Supplier

What Is Stacking Rack

A stacking rack, also known as a stack rack or stackable pallet rack, is a type of storage rack designed for versatile and space-efficient storage. These racks are typically made of durable materials like steel and feature stackable frames that can be easily assembled and disassembled as needed. Stacking racks are commonly used in warehouses, distribution centers, and manufacturing facilities to store palletized goods or other bulky items. They allow for vertical stacking to maximize storage space while providing easy access to stored items.

Customizable Stacking Rack Specifications

The size of our common stacking rack is L1200*D1000*H1000, of course, it can be customized according to the actual storage needs. When customizing stacking racks, the size, carrying capacity and stackable height of the stacking racks are the key considerations. Generally speaking, from the point of view of safety and economy, when the carrying capacity of the stacking rack does not exceed 2000kg, stacking 3 to 5 layers is more appropriate.

| Size(mm) | Color | Stackable Layers | Load Capacity |

|---|---|---|---|

| L1200*D1000*H1000 | Orange | 5 layer | 1000kg/layer |

| L1200*D1000*H1000 | Blue | 4 layer | 1500kg/layer |

| L1200*D1000*H1000 | Red | 3 layer | 2000kg/layer |

| Customizable | Customizable | Customizable | Customizable |

Stacking Racking Design

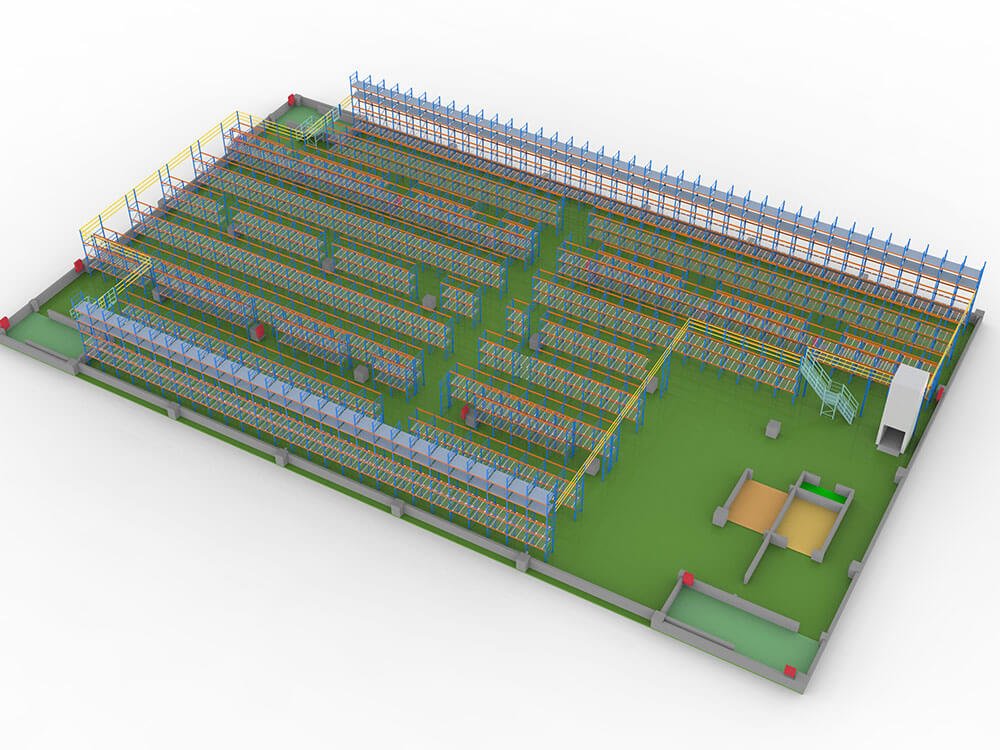

Stacking Racking Layout Design

Please send us detailed data such as warehouse size, cargo size, etc. Our engineers will design a reasonable layout plan for you.

Three-dimensional drawing of stacking racking

The exact dimensions of the racks, the load and the number of tiers will be presented to you in a three-dimensional drawing.

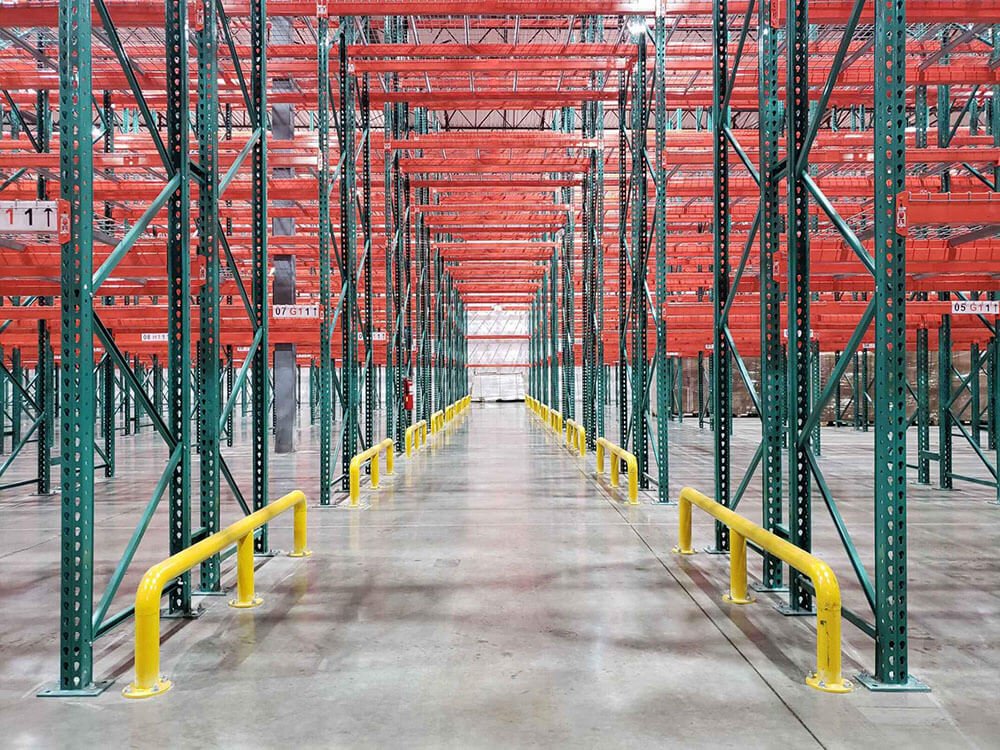

Rendering of Stacking Racking

If the project is complex, we can also produce installation drawings for you, and we can even produce renderings if necessary.

Why Choose Lracking Custom Stacking Racking Systems

Selecting Lracking for tailored stacking racking solutions provides a range of advantages. Firstly, Lracking stands as one of China’s top ten manufacturers of portable stack racks, boasting over sixteen years of manufacturing expertise. Secondly, Lracking’s certifications, including ISO9001, CE, AS4084, and TUV, ensure product durability, safety, and compliance with industry standards. Lastly, situated in Dongguan, a prominent global manufacturing hub, Lracking offers products known for their exceptional value. Procuring stack racks from Lracking in China presents an opportunity to reduce costs significantly while maintaining high-quality standards.

Application of Stacking Racking System

tire storage stacking rack

Stacking racks for tire storage are specifically designed to safely and efficiently store tires in warehouses or distribution centers. Stacking racks for tire storage are designed to accommodate the size of tires commonly used in the industry, including passenger car tires, truck tires, or specialty tires.

fabric roll storage racks

Stacking racks for fabric storage are designed to efficiently organize and store rolls of fabric in warehouses, textile factories, or retail distribution centers. Stacking racks come in various sizes and capacities to accommodate different sizes and weights of fabric rolls. They can range from small racks for lightweight rolls to larger racks capable of holding heavy-duty rolls.

stack lumber racking

Stacking racks for lumber storage are specialized storage solutions designed to efficiently organize and store lumber in warehouses, lumber yards, or construction sites. These racks are designed to be stackable, allowing lumber to be stored vertically to maximize floor space utilization. They can be stacked several units high, depending on the weight capacity and stability of the racks. The racks feature an open design with sturdy posts or beams to support the lumber and allow airflow. This design facilitates easy loading and unloading of lumber using forklifts or manual handling equipment.

Frequently Asked Questions about Stacking Racking Systems

How high can the stacking racks be stacked?

The stacking height of a stacking rack can vary depending on a number of factors, including the design of the rack, the weight and size of the items being stacked, and safety regulations. Generally, stacking racks can be stacked three to five units high to effectively maximize vertical storage space. However, adherence to manufacturer guidelines and safety standards is critical to preventing accidents and ensuring stability.

Can the stacking racks be folded?

Yes, portable stacking racks can often be folded or collapsed when not in use to save space and facilitate storage or transportation. Folding stacking racks typically feature hinges or mechanisms that allow them to collapse into a more compact form, making them easier to store and transport when empty or not in use. This feature enhances their versatility and usability in various storage or logistics applications, as they can be quickly set up or folded down as needed.

How many types of stacking racks are there?

There are many different types of stacking racks including nestable stacking racks, stackable racking, folding stacking racks, tire stacking racks, pallet stacking racks, fabric stacking racks, lumber stacking racks and more. There are many other types of stacking racks available, each tailored to specific storage requirements and industry applications.

What is the load capacity of the stack rack?

The load capacity of a stack rack is closely related to its design, dimensions and materials of manufacture. Generally, stacker racks are designed for storing and transferring heavy loads, with load capacities ranging from 1000-3000kg. To ensure safety during the use of the stack rack, it is important to observe the load limits recommended by the manufacturer.

What are the standard sizes of stack racks?

Stacking rack sizes will vary depending on their specific application. However, the most common size for stacking racks is L1200*D1000*H1000mm. This size will meet the storage and transloading needs of most warehouses. If you require other sizes of stacking racks, please contact the Lracking stacking rack manufacturer for customization.

How much does the stacking rack cost?

Stacking racks are simpler in construction, so their cost is not too high. Typically, the cost of a standard size stacker with a 1000kg load capacity is between $120-$200. However, larger or more specialized stacking racks can be more expensive, especially if they are made of high quality materials or include features such as foldable or adjustable components. To get an accurate cost estimate, it is best to contact a China stacking rack manufacturer directly.