Mezzanine floors are intermediate floors that are built between the main floor and the ceiling of a building. They are often used in warehouse and industrial spaces to create additional storage or work areas.

For warehouses, the mezzanine floor helps to utilize the space of the warehouse and ensures the best use of existing warehouse space. In this article, we will show you how mezzanine floor design is done and what factors you need to consider.

Things to keep in mind while designing mezzanine floors

When designing mezzanine floors, there are several key considerations to keep in mind.

Space Utilization And Optimization

Mezzanine floors are advantageous as they maximize vertical space, increasing storage capacity without expanding the building’s footprint. This enhances warehouse layout efficiency and operational effectiveness.

To achieve optimal design, several factors need to be taken into account:

- Ceiling Height: The height of the ceiling must be considered to ensure ample headroom on both levels.

- Product Size and Shape: The dimensions and configurations of the products stored on the mezzanine floor should be taken into account to optimize storage layout and accessibility.

- Inventory Accessibility: For seamless operations, accessibility to the inventory situated on the mezzanine floor is of utmost importance. Adequate access points and clear aisles should be designed to facilitate the easy movement of goods.

- Interference with Building Systems: Proper planning is needed to ensure that the mezzanine floor does not obstruct ventilation, lighting, or sprinkler systems in the building.

Design Of Mezzanine Floors Should Consider Load-Bearing Capacity

Mezzanine floors are typically constructed using lightweight materials like steel or wood, so they are not meant to support excessive weight.

When designing the mezzanine floor, the weight of the stored products and equipment must be carefully calculated to ensure the floor can handle the load.

- Load Distribution: Even distribution of the load on the mezzanine floor is essential to prevent overloading in certain areas. This helps maintain structural integrity and prevents uneven settling or damage.

- Safety and Future Expansion: When determining the load-bearing capacity of the mezzanine floor, a safety margin should be considered to accommodate potential future expansion or changes in storage requirements.

Design Of Mezzanine Floors Must Comply With Local Building Codes

Before you start designing your mezzanine floor, you need to check the local building codes and regulations that apply to your area. These codes may vary depending on the location, size, and purpose of your mezzanine floor.

They may also require you to obtain certain permits or approvals before you can install your mezzanine floor. One of the main reasons why you need to comply with these codes is to ensure the safety of your staff and property.

Mezzanine floors must meet certain standards for fire resistance, structural stability, and emergency access. They must also have adequate ventilation, lighting, and sprinkler systems. By following these codes, you can avoid potential hazards and liabilities.

Various Types Of Mezzanine Floor Designs

Depending on your needs and preferences, you can choose from several mezzanine floor designs. Some popular options include

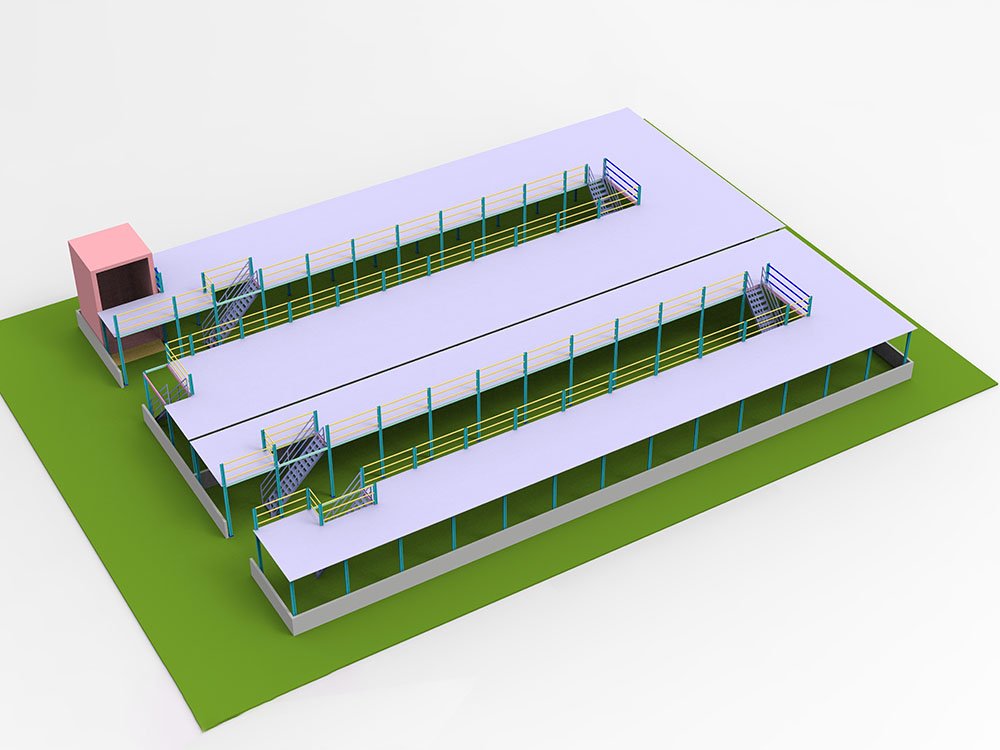

1. Free-Standing Mezzanine Floors: These freestanding structures derive their stability from supporting columns or pillars. This design allows for easy installation, relocation, and adaptability, as they are not restricted by the current walls or columns of the building.

2. Structural Mezzanine Floors: Integrated into the existing structure of the building, these mezzanine floors utilize the support of walls or columns. They provide enhanced stability and durability compared to free-standing options. However, they demand meticulous planning and construction, resulting in reduced flexibility.

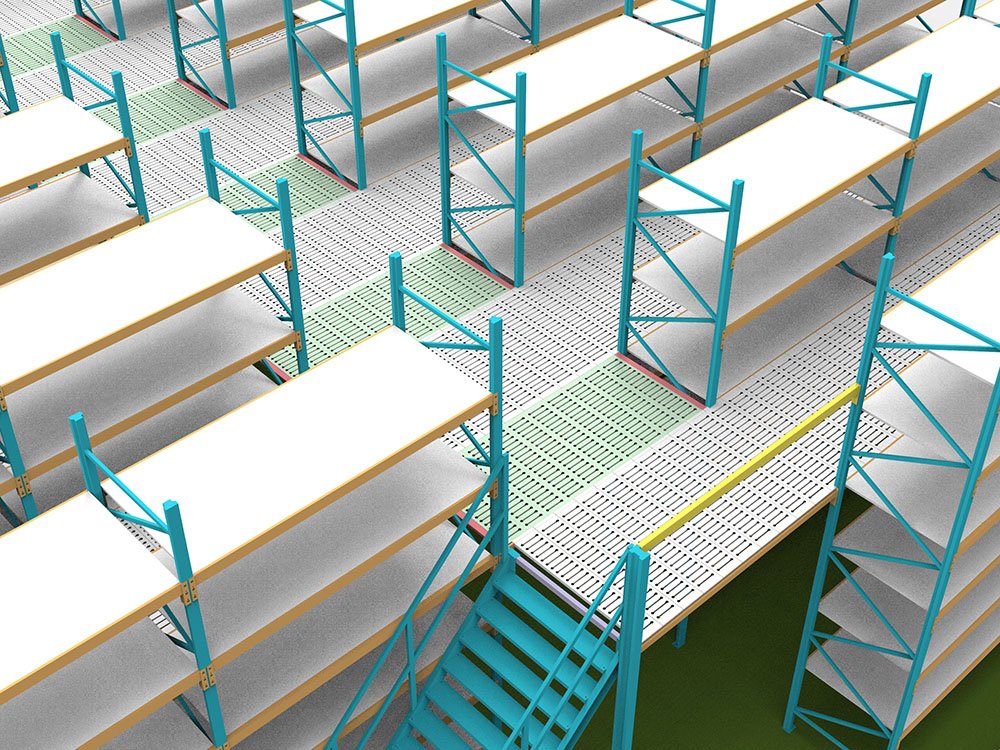

3. Rack-Supported Mezzanine Floors: Utilizing existing racking systems, these mezzanine floors leverage the racks for support, thereby generating extra storage space above. While they offer cost-effectiveness and space efficiency, they might potentially hinder access and reduce the visibility of the products situated on the racks.

4. Shelf-Supported Mezzanine Floors: Similar to rack-supported mezzanine floors, these designs use shelves instead of racks for support. They provide additional storage space above and below the shelves and are suitable for storing small to medium-sized products manually.

Customization and Flexibility

One of the advantages of mezzanine floors is that they can be customized and adapted to your specific needs and preferences. You can choose the size, shape, color, material, and finish of your mezzanine floor according to your requirements. You can also add features such as windows, doors, partitions, railings, or flooring to enhance its functionality and appearance.

Moreover, you can design your mezzanine floor in a way that allows for future expansion or reconfiguration. For example, you can use a modular design that consists of prefabricated components that can be easily assembled or disassembled. You can also leave some space for adding more levels or sections to your mezzanine floor if needed.

Integration Of Mezzanine Floor Design With Warehouse Racking Systems

Mezzanine floors are often used in conjunction with warehouse racking systems to create a complete storage solution for your warehouse or industrial space.

However, to achieve this, you need to ensure that your mezzanine floor design is compatible and integrated with your racking systems. Before making your decision, there are certain elements you should take into consideration, such as

The Compatibility Of Mezzanine Floors With Conveyor Equipment

If you use conveyor equipment to transport your products between different levels or areas of your warehouse, you need to make sure that your mezzanine floor design does not obstruct or interfere with it.

You need to leave enough space and clearance for the conveyor equipment to operate smoothly and safely. You also need to align your mezzanine floor with the conveyor equipment to facilitate the loading and unloading of your products.

Interaction Of Mezzanine Floors With Pallet Racking Systems

If you use pallet racking systems to store your products on pallets, you need to consider how your mezzanine floor design will affect them.

You also need to ensure that your mezzanine floor does not reduce the height or width of your pallet racking systems, as this may limit your storage capacity or accessibility.

You also need to ensure that your mezzanine floor does not compromise the stability or safety of your pallet racking systems, as this may cause damage or injury.

The Interface Of Mezzanine Floors With Existing Infrastructure

When designing a mezzanine floor for your warehouse or industrial space, it is essential to assess your existing infrastructure thoroughly, such as electrical wiring, plumbing, and HVAC systems.

Proper planning is necessary to avoid damage or disruption to these systems during the installation process.

It’s equally important to ensure that these systems remain accessible and fully functional after the mezzanine floor is in place. Careful coordination and consideration of these factors are essential for a successful mezzanine floor integration.

Safety Features In Mezzanine Floor Design

Safety is a paramount concern when designing mezzanine floors. You need to ensure that your mezzanine floor design incorporates adequate safety features to protect your staff and property from potential hazards and accidents.

Some of the common safety features that you need to include are as follows:

Guardrails and Handrails

For the safety of both people and objects, installing sturdy and durable guardrails is essential. These guardrails should be placed along the perimeter as well as around any gaps or openings.

These barriers serve to prevent accidental falls and should be sufficiently high to deter anyone from attempting to climb over them. Their purpose is to provide a reliable safety measure to protect people and objects from potential hazards associated with the mezzanine floor’s elevated height.

Stairs and Passageways

To ensure easy and safe movement of individuals and products, the means of access and egress for your mezzanine floor should be strategically designed and positioned.

These access points should have adequate width, height, and slope to accommodate the anticipated traffic and load. Furthermore, the incorporation of slip-resistant handrails, steps, and landings, along with proper lighting, is crucial for safety.

Fire Safety Measures

To effectively prevent or control the spread of fire on your mezzanine floor, it is essential to implement the following measures:

- Fire-Resistant Materials: Utilize fire-resistant materials in the construction and furnishing of the mezzanine floor to minimize the risk of fire ignition and spread.

- Fire Alarms: Install reliable fire alarm systems to promptly detect any signs of fire and alert occupants, allowing for timely evacuation.

- Fire Extinguishers: Strategically place appropriate types of fire extinguishers throughout the mezzanine floor to enable quick response to small fires before they escalate.

- Fire Doors: Install fire doors that are designed to contain and impede the spread of fire, providing a safe exit path for occupants.

- Sprinkler Systems: Consider installing a sprinkler system that automatically activates in the event of a fire, helping to suppress and control the flames.

- Compliance with Fire Codes and Regulations: Ensure that all fire safety measures and installations on the mezzanine floor adhere to the fire codes and regulations specific to your area, as they are essential guidelines for fire prevention and protection.

Staff Training And Awareness

Educate staff on proper mezzanine floor use and maintenance:

- Regular Training: Teach staff about safety, operation, and maintenance through comprehensive training programs.

- Safety Manual: Provide a detailed guide on proper usage and maintenance.

- Signage: Use visual aids to remind staff of safety guidelines and potential hazards.

- Supervision: Assign supervisors to ensure safety protocol compliance and respond to issues.

- Culture: Foster a positive safety culture by recognizing responsible behavior and reinforcing safety measures.

These actions create a safe and productive work environment by educating and informing staff members.

How To Get Free Mezzanine Floor Design?

If you are interested in getting a free customized mezzanine floor design for your warehouse or industrial space, contact a reputable mezzanine floor manufacturer who will provide you with a professional mezzanine floor design program.

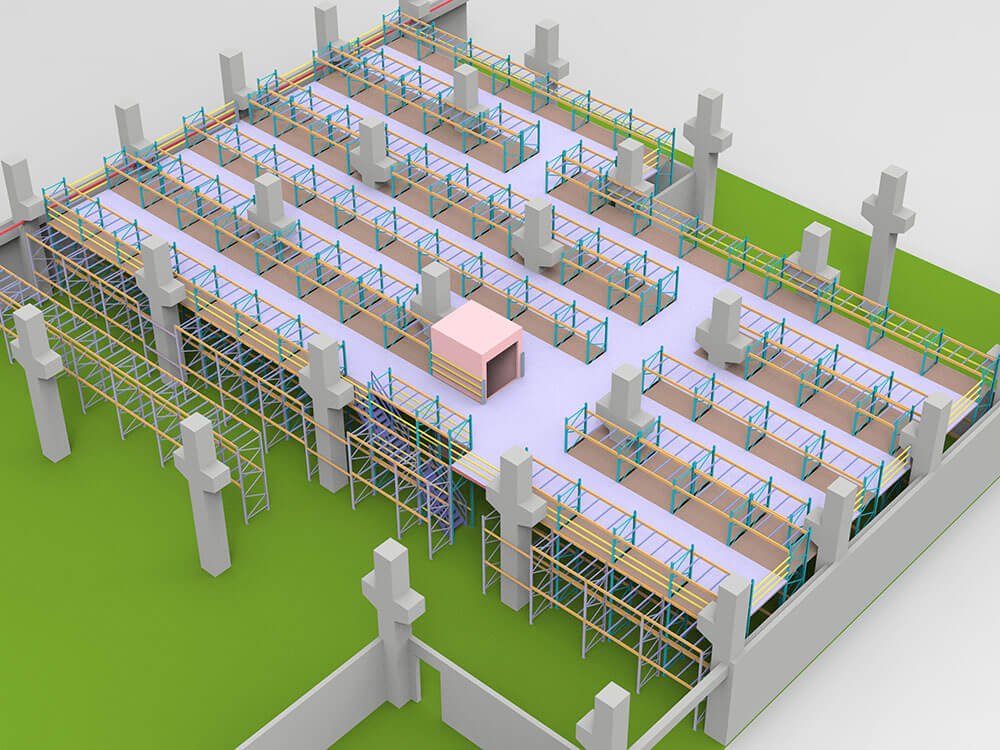

One such manufacturer is Lracking, a professional mezzanine floor manufacturer with a dedicated design department and experience in designing and installing high-quality mezzanine floors for various industries. Lracking offers a free quotation and a free 3D design for your mezzanine floor project.

All you need to do is provide them with your warehouse dimensions, pallet specifications, and load requirements, and they will give you a free mezzanine floor design program.

You will receive a detailed drawing and a realistic rendering of the mezzanine floor plan for your approval before production. Lracking will help you make the most of your available space with our high-quality mezzanine floor products and services.