Racking and warehouse go hand in hand, unless you don’t have the right racking system in place, your warehouse can never look organized or have an adequate flow of operations. There are multiple types of racking systems and each system has its own varied styles. A pallet racking system is one of the most commonly opted choices when it comes to warehouse racking.

Pallet racking systems offer varied styles that cater to compatibility with the nature of items stored followed by their excellent operational efficiency. If you are looking to learn about different types of pallet racking systems with varied styles, the guide below can help you. So, let’s take a look.

Overview of Pallet Racking Styles

What Defines a Style?

Pallet racking types have their designs which differentiate them, the layout of their vertical frames and beams create a specific style. These components are assembled based on the required compatibility by the racking systems.

Every style comprises unique characteristics that differ in terms of connection as well as patterns. The features of design are significant because they help to accommodate the storage of varied products.

Importance of Choosing the Right Style

Choosing the right pallet style is very important to ensure that it fits well with the systems that are already present in your warehouse. It helps avoid replacing these systems which are costly and also simplifies the inventory management system.

When you incorporate different styles of pallet racks in your warehouse you can make the best use of their complex layouts. For instance, the teardrop style can be assembled without any tools and the bolted systems need labor. Moreover, when you opt for the right style you can enhance the efficiency of your warehouse, and the required adjustability and stability are achieved.

Popular Pallet Racking Styles

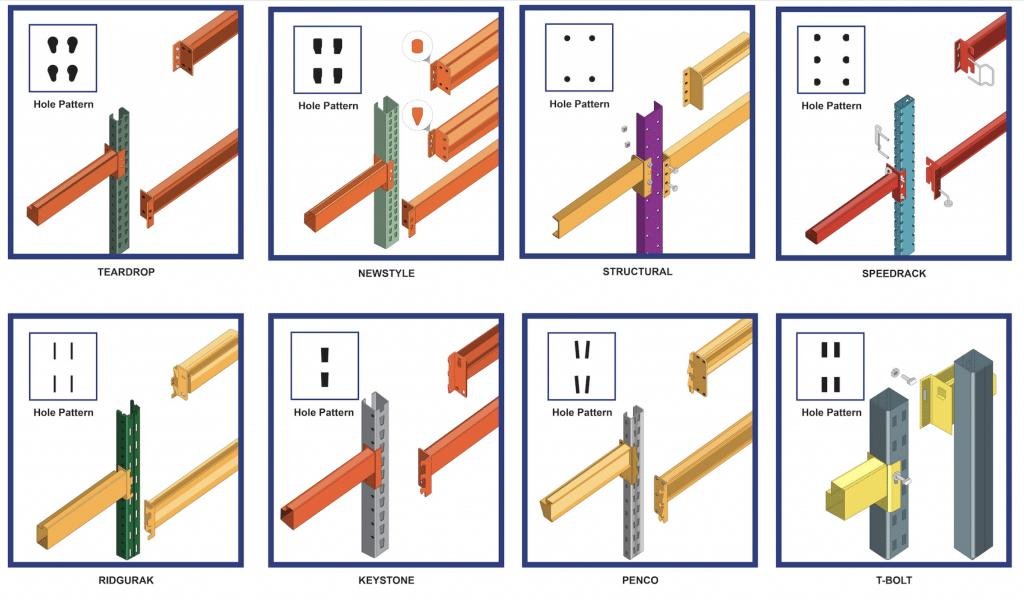

There are various styles of pallet racking and each has its own features and suitability, these varied styles are discussed below.

Teardrop Style

The teardrop style of racking is a very common style and it has a connector on the slot or load beam. The inverted teardrop pattern on the upright makes it easy to install and lock.

Features:

- It comprises teardrop-shaped holes for connecting the beams easily.

- This system of pallet racking is very easy to assemble as it doesn’t need any tools.

Advantages:

- It is compatible with all types of systems that usually exist in a warehouse and can be chosen for the expansion of these existing systems.

- The installation process is very quick and simple which reduces the cost of labor and time spent in installation.

Applications:

- It is suitable for general warehouses where versatile inventory of varied sizes and types can be stored.

- It is suitable for such facilities that need scalability and adjustability in their storage.

Sammons Style

Sammons-style pallet rack has a keyhole-shaped slot which offers a very sturdy design and it even meets the industrial storage applications.

Features:

- Sammons-style racks consist of keyhole slots on the upright so that the beam connections can be secured.

- There is a strong mechanism of locking which enhances the structural stability.

Advantages:

- It offers high stability and durability making it suitable for heavy loads.

- It can withstand challenging environments.

Applications:

- Sammons-style racking systems are used in such facilities where storage is heavy-duty.

- It is even suitable for such applications where storage systems having reliability and strength are needed.

Newstyle

The new style pallet racks have a vertical layout and have slots in square or rectangular shape so that the system can be adjusted.

Features:

- It comprises rectangular and square slots on the upright so that the beam can be adjusted.

- The connections of beams are highly adjustable so that different loads can be adjusted.

Advantages:

- It offers high flexibility and can be adjusted very quickly.

- It is suitable for such a warehouse where the storage layout needs frequency modifications.

Applications:

- It is suitable for such environments where the sizes and volume of products vary.

- Businesses that need a shift in their operational storage requirements tend to incorporate these racks.

Structural Style

The structural style pallet racks offer high durability and are usually opted for environments where heavy-duty storage is needed.

Features:

- It offers high stability due to the bolted connections.

- It consists of steel construction which can withstand heavy loads.

Advantages:

- It offers high strength and can hold the weight of bulky items.

- It offers wear resistance and also ensures long-term durability.

Applications:

- Structural-style pallet racks are used in industries where stable racks are required.

- It is suitable for cold storage as they can resist temperature changes due to their sturdy nature.

Speedrack Style

Speedrack style has a pattern of holes and beams with no hooks and rather brackets. The u-shaped brackets are installed to secure uprights and beams.

Features:

- Comprises a bracket system that offers quick installation.

- It is very lightweight which makes it easy to handle.

Advantages:

- Simple installation helps in reducing the cost associated with laborers.

- Due to its cost-effectiveness, it is suitable for such businesses that have limited budgets.

Applications:

- Speedrack styles are suitable for warehouses that need lightweight storage due to limited space.

- It offers high flexibility and can be a suitable choice for such warehouses that have no heavy inventory storage.

Ridg-U-Rak Style

Ridg-u-rak comprises a slot and hook connection with the rectangular slots present on the uprights. They have beams with hooked flanges and thinner beams.

Features:

- The pin and hook connection offered by this style ensures stability in assembling.

- It is designed to offer compatibility with other systems of ridg-u-rak styles.

Advantages:

- It is very durable and can be used in such setups where chances of wear and tear are high.

- They are highly customizable and may cater to a wider range of storage requirements.

- It can integrate easily with the similar ridg-u-rak systems offering high modifictaion.

Applications:

- It is opted for such warehouses that require storing a wide range of products.

- It is used for retail stores as well where durable and adjustable storage systems are needed.

Keystone Style (Republic)

Keystone-style racks use a slot and hook connection. It comprises a hole pattern in the form of a trapezoid on the upright; the slots are present on the column face at the center.

Features:

- Keystone-shaped slots create a very secure beam connection.

- It comprises locking mechanisms that are strong and offer improved stability.

Advantages:

- It offers stability which can handle heavy loads of goods.

- These are mostly opted-in systems that are existing and also offer high compatibility.

Applications:

- Keystone-style racks are suitable for such racking systems which need some more modifications.

- These are even suitable for environments that can handle inventory that is dense and heavy.

Penco Style

Penco racks use slot and hook connections and the uprights have narrow slots in the slanted style side by side. The beam of this style rack also has slant hooks that can be fixed in the slots.

Features:

- There are rectangular holes that can fix the uprights with the beam.

- It offers a locking system that improves the safety and stability of the rack.

Advantages:

- The durability of this style is commendable and hence can withstand harsh industrial usage.

Applications:

- It is mostly opted in factory-like steps as they need storage systems that can hold heavy weights.

- The automobile industry mostly opts for it to store automobile parts of varied sizes and weights.

T-Bolt Style

T-bolt racking is a very commonly opted style of pallet racking that has rectangular slots on the load beams and columns. They’re attached with the uprights using larger-sized bolts.

Features:

- The bolted connections on the rack ensure stability and support.

- It is suitable for heavy-duty storage of items.

Advantages:

- The t-bolt style pallet racks are suitable for holding bulky products as they are highly stable.

- They offer durability when subjected to extreme industrial usage.

Applications:

- T-bolt styles are suitable for such warehouses that need to be strength-oriented racking systems.

- They are mostly opted for manufacturing facilities that can store heavy machinery.

Comparing Pallet Racking Styles

The different types of pallet racking styles can be compared with one another based on varied factors as discussed below.

Compatibility

The teardrop pallet racks are highly compatible and can be integrated with various racking systems. However, the structural and keystone racking systems offer limited compatibility and need either similar manufacturers or are compatible with the older rack styles. Whereas, the speedrack system can be compatible with the racks that have bracket systems similar to theirs.

Strength and Durability

The speedrack is a lightweight racking system and can hold only light weights hence is not very durable. However, the structural and keystone racks are highly durable and can be used for heavy-duty storage. Teardrop pallet racks are also moderately durable and can hold a moderate weight of general goods.

Ease of Installation

The ease of installation among different pallet racking styles also varies. Teardrop systems are very easy to install and don’t even need any tools, and the speed rack system is also easily installed with brackets. However, the structural racking system is hard to install and needs tools for bolted connections. The existing legacy systems in the keystone racking make it easier to install it.

Cost Considerations

The selection of pallet racking systems is also based on the budget and every style varies in terms of its cost. The teardrop and speed rack is an affordable style of pallet rack and is suitable for moderate to light product storage.

However, for the heavy-duty storage structural and keystone racks are needed which are expensive.

| Style | Compatibility | Durability | Ease of Installation | Cost |

| Teardrop | High | Moderate | Very Easy | Affordable |

| Structural | Limited | Very High | Moderate | Expensive |

| Keystone (Republic) | Limited | High | Easy | Moderate |

| Speedrack | Moderate | Low | Very Easy | Affordable |

Factors to Consider When Choosing a Racking Style

When choosing a pallet racking style some of the considerations to have in place are as follows:

Existing Systems

The compatibility between the existing setup with the new style of rack is very important. You must look forward to opting for such a style that can easily integrate with the existing racks. It helps ensure a smooth modification that reduces cost and improves operational efficiency.

Load Requirements

Every racking style has a different weight capacity. Based on your products you have to choose the racking style. If you have to store heavy items you can go for the structural racks. If you have to look for racking styles suitable for low-weight products, speed racks, and teardrop styles are more suitable.

Budget

Conduct an assessment of your budget and choose a style that balances the investment and benefits in the long run. If you choose the structural style it will cost you more but is durable in the longer run. Whereas the affordable choices consist of speedrack and teardrop they cannot hold heavy items.

Warehouse Layout

The warehouse layout is crucial when choosing the rack styles. Select the rack style that is according to the space and can accommodate forklifts and other automated systems you might be incorporating. Opt for adjustable styles like newstyle and teardrop pallet racks as they are highly flexible.

Advantages of Matching Styles

It is very important to ensure that across your warehouse the style of pallet is consistent and it offers multiple benefits some of which are as follows:

Enhanced Compatibility

Opting for a similar style of racking ensures the integration of racks with one another when moving toward expansion. Such compatibility helps in reducing the cost of replacement and even helps to upscale in a convenient way.

Reduced Maintenance Costs

When you have a consistent system of racks across the entire warehouse the cost of replacement of components is reduced as you can source them in bulk. Also, opting for standard designs you can also avoid the need to maintain varied styles of racking and other challenges associated with maintenance.

Improved Safety

Matching the consistent racking styles helps avoid installation errors and also ensures structural matching. Workers are more familiar with the system and hence they can handle the products in a safe way. It even helps to avoid accidents and safety standards are followed in a better way.

Conclusion

Understanding the pallet racking styles is very crucial to ensure that you implement the right one in your warehouse. As you have read the guide above you must understand each style and where it would suit. So, contact us at Lracking and we can customize the racking styles for your warehouse.