China ASRS Automated Storage And Retrieval System Supplier

What Is ASRS System

ASRS stands for Automated Storage and Retrieval System. It’s a sophisticated inventory management system that uses automated machinery to quickly and accurately store and retrieve goods from defined storage locations. ASRS systems typically involve a combination of computer-controlled robotic systems, conveyor belts, and storage racks to efficiently manage inventory in warehouses or distribution centers. They are designed to maximize storage density, minimize human intervention, and increase operational efficiency in handling goods.

Benefits of using ASRS storage system

Using an ASRS (Automated Storage and Retrieval System) offers several benefits:

1. Increased Efficiency: ASRS systems automate the storage and retrieval process, reducing the time and labor required for these tasks. This leads to faster operations and increased productivity.

2. Space Optimization: ASRS systems are designed to maximize vertical storage space, allowing warehouses to store more goods in a smaller footprint. This is especially beneficial for facilities with limited space or high land costs.

3. Improved Accuracy: Automation reduces the risk of human error in inventory management, leading to higher accuracy in stock tracking and order fulfillment.

4. Enhanced Safety: ASRS systems reduce the need for manual handling of heavy or bulky items, reducing the risk of workplace accidents and injuries.

5. Real-time Inventory Management: ASRS systems are often integrated with warehouse management software, providing real-time visibility into inventory levels, locations, and movement. This helps companies make better-informed decisions and optimize inventory control.

Overall, ASRS systems offer a cost-effective solution for streamlining warehouse operations, increasing storage capacity, and improving inventory accuracy and control.

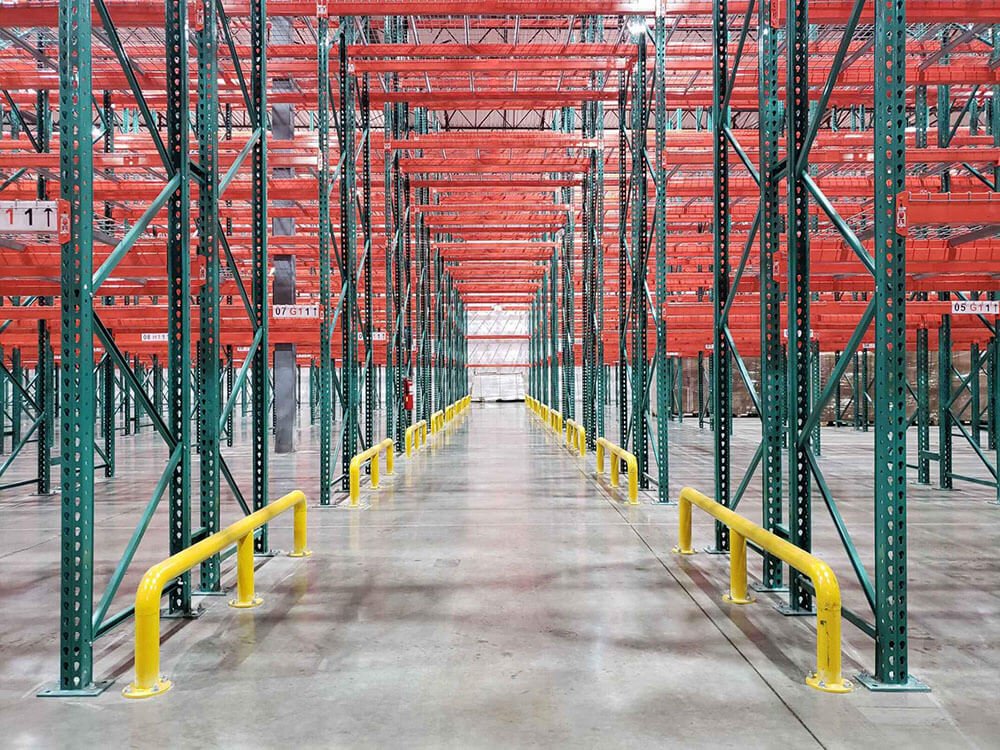

ASRS Automated Storage And Retrieval System Design

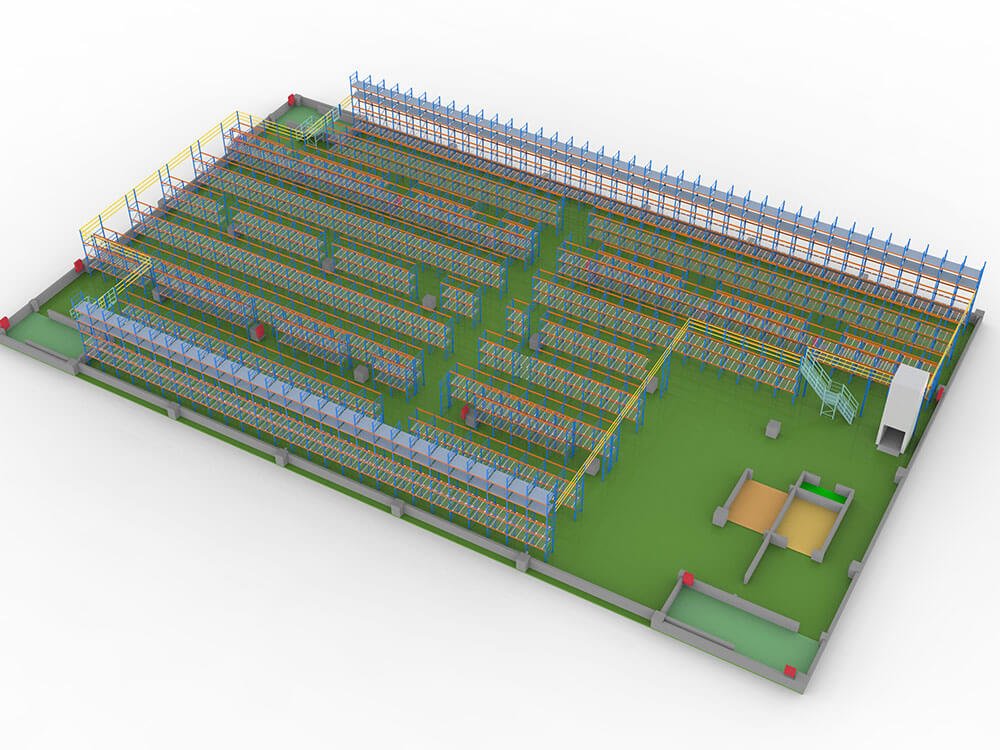

ASRS Storage System Layout Design

Please send us detailed data such as warehouse size, cargo size, etc. Our engineers will design a reasonable layout plan for you.

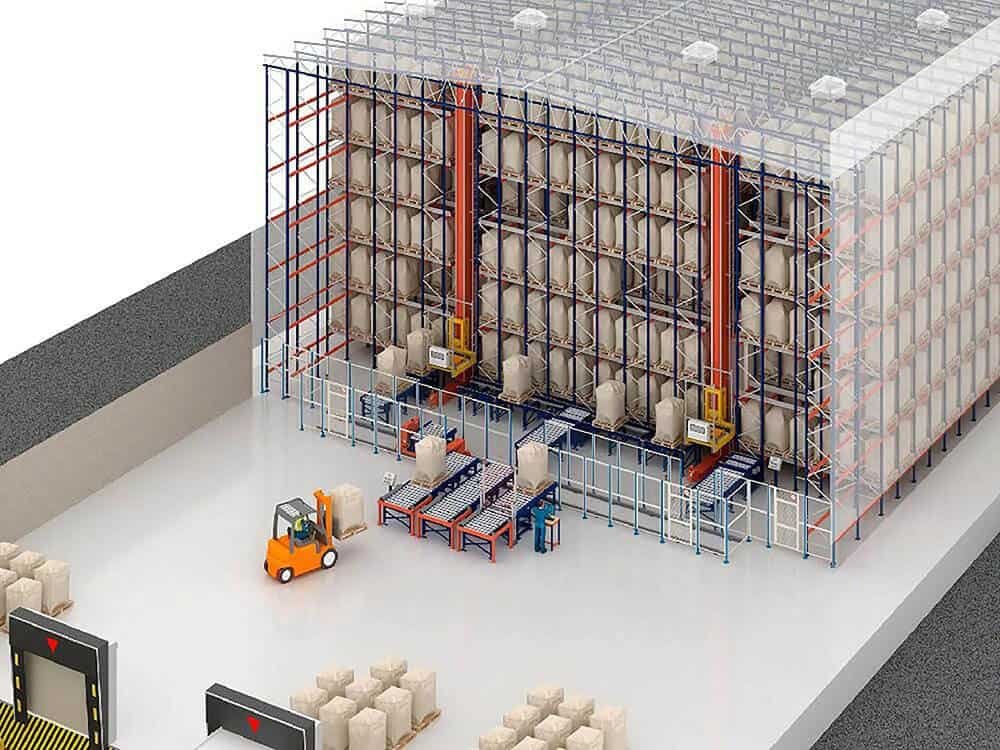

Three-dimensional drawing of ASRS Storage System

The exact dimensions of the racks, the load and the number of tiers will be presented to you in a three-dimensional drawing.

Rendering of ASRS Storage System

If the project is complex, we can also produce installation drawings for you, and we can even produce renderings if necessary.

The most common types of ASRS systems

1. Unit Load ASRS: Designed to handle large, palletized loads, unit load ASRS uses cranes or shuttles to transport pallets to and from storage locations within the system.

2. Mini Load ASRS: Mini load ASRS are used for smaller items or cases and typically use smaller cranes or shuttles to retrieve and store goods from shelves.

3. Vertical Lift Modules (VLMs): VLMs consist of trays or bins stored vertically in a column. An automated lift mechanism retrieves the requested tray and delivers it to an access point for picking.

4. Horizontal Carousels: Horizontal carousels consist of rotating shelves that bring items directly to the operator for picking. They are often used in goods-to-person picking systems.

5. Vertical Carousels: Similar to horizontal carousels, vertical carousels consist of rotating shelves, but they move vertically rather than horizontally. They are suitable for storing and retrieving small parts or items.

6. Robotic ASRS: These systems use robotic arms or vehicles to automatically pick, store, and transport items within the storage system. They offer high flexibility and adaptability to changing warehouse needs.

Application of ASRS Storage Systems

ASRS for e-commerce warehouse

ASRS (Automated Storage and Retrieval Systems) are highly beneficial for e-commerce warehouses due to their ability to efficiently manage inventory, optimize storage space, and streamline order fulfillment processes. With the rapid growth of e-commerce and the increasing demand for quick order processing and delivery, ASRS systems offer several advantages such as high-speed storage and retrieval, accurate inventory tracking, and seamless integration with warehouse management systems (WMS) and order management systems (OMS). Additionally, ASRS can help e-commerce warehouses maximize their storage capacity, minimize labor costs, reduce picking errors, and improve overall operational efficiency to meet the demands of online shoppers effectively.

ASRS used in logistics centers

ASRS (Automated Storage and Retrieval Systems) are widely used in logistics centers to streamline warehouse operations and improve efficiency. These systems are employed to automate the storage and retrieval of goods, allowing for high-density storage and efficient utilization of warehouse space. ASRS systems in logistics centers enhance inventory management by providing accurate tracking of goods, reducing picking errors, and optimizing inventory turnover. They also facilitate faster order fulfillment by automating the retrieval process, minimizing waiting times, and increasing overall throughput. Overall, ASRS plays a crucial role in enhancing the productivity and effectiveness of logistics centers by automating key warehouse tasks and optimizing storage processes.

ASRS systems for the food industry

ASRS (Automated Storage and Retrieval Systems) are increasingly utilized in the food industry to enhance storage efficiency and maintain product integrity. These systems offer controlled environments for storing perishable goods, ensuring temperature and humidity levels are maintained to preserve food quality. ASRS can also facilitate FIFO (First In, First Out) inventory management, crucial for managing expiration dates and minimizing waste. Additionally, ASRS systems in the food industry improve traceability by providing accurate records of product movement, enhancing food safety and compliance with regulations. Overall, ASRS systems play a vital role in optimizing storage and distribution processes in the food industry, ensuring product freshness, safety, and efficiency from storage to delivery.

Frequently Asked Questions About ASRS Storage Systems

What are the components of the ASRS system?

The components of an Automated Storage and Retrieval System (ASRS) typically include storage structures such as racks or shelves where goods are stored. These structures are integrated with automated retrieval systems, which consist of machinery like cranes, shuttles, or robotic arms for retrieving items from storage locations. Control software manages inventory, directs storage and retrieval operations, and interfaces with other warehouse management systems. Input and output stations facilitate the loading and retrieval of items, often located near receiving docks or shipping areas. Sensors and safety systems ensure safe operation by detecting item presence and monitoring equipment status.

Can you design my ASRS system for free?

Certainly! If you’re looking for an ASRS system tailored to your warehouse needs, we’re here to help. As an ASRS system manufacturer, we offer complimentary design services to ensure that the solution we provide aligns perfectly with your requirements. Our team of experts will work closely with you to understand your warehouse layout, inventory characteristics, throughput goals, and any specific preferences or constraints you may have. With this information, we’ll create a customized ASRS system design that optimizes space utilization, enhances efficiency, and maximizes productivity in your warehouse operations. Get in touch with us today to get started on designing your ideal ASRS system at no cost to you!

Precautions for using the ASRS system.

When using an ASRS (Automated Storage and Retrieval System), several precautions should be taken to ensure safe and efficient operation. Firstly, personnel must be adequately trained on how to interact with the system safely, including understanding emergency procedures and how to handle system errors or malfunctions. Regular maintenance and inspections should be conducted to identify and address any potential issues before they escalate. Additionally, load capacities and weight limits should always be adhered to, and proper stacking and retrieval techniques should be followed to prevent accidents or damage to goods. It’s also essential to keep the work area clear of obstacles and clutter to facilitate smooth operation of the ASRS system. Lastly, ongoing monitoring and supervision of the system’s performance are crucial to identify any issues early and implement corrective measures promptly.

Is it expensive to build an ASRS system?

Yes, building an ASRS system can be expensive due to the high initial investment required for the sophisticated equipment and technology involved. The cost depends on various factors such as the size and complexity of the system, the type of machinery used, the level of automation, and customization requirements. Additionally, ongoing maintenance and operational costs should also be considered. However, the benefits of increased efficiency, space optimization, and labor savings over time can often justify the initial investment for many businesses.

How do I determine if the ASRS system is right for my warehouse?

To determine if an ASRS (Automated Storage and Retrieval System) is suitable for your warehouse, start by assessing your warehouse size and layout to ensure it can accommodate ASRS equipment effectively. Evaluate your inventory volume and complexity to see if it justifies the implementation of an ASRS system, especially if you have high-density storage needs and numerous SKUs. Consider your order fulfillment requirements and whether an ASRS system can enhance speed, accuracy, and efficiency in storage and retrieval processes. Calculate potential labor savings and return on investment by comparing the costs and benefits of implementing an ASRS system. Additionally, assess scalability, technical expertise, and support requirements to ensure the ASRS system aligns with your long-term business goals and operational needs. Consulting with ASRS system providers and experts can also help in making an informed decision.

How is the ASRS system installed?

The installation process of an ASRS (Automated Storage and Retrieval System) involves several steps. Firstly, the site is prepared, including ensuring adequate space, infrastructure, and utilities. Next, the ASRS equipment is delivered and assembled according to the manufacturer’s specifications, often requiring specialized installation teams. Electrical and mechanical components are integrated, and safety measures are implemented to comply with regulations and standards. Software configuration and integration with existing warehouse management systems are then conducted to enable seamless operation and communication between ASRS components and other warehouse processes. Finally, comprehensive testing and commissioning are performed to ensure the ASRS system functions correctly and meets performance requirements before being put into full operation.