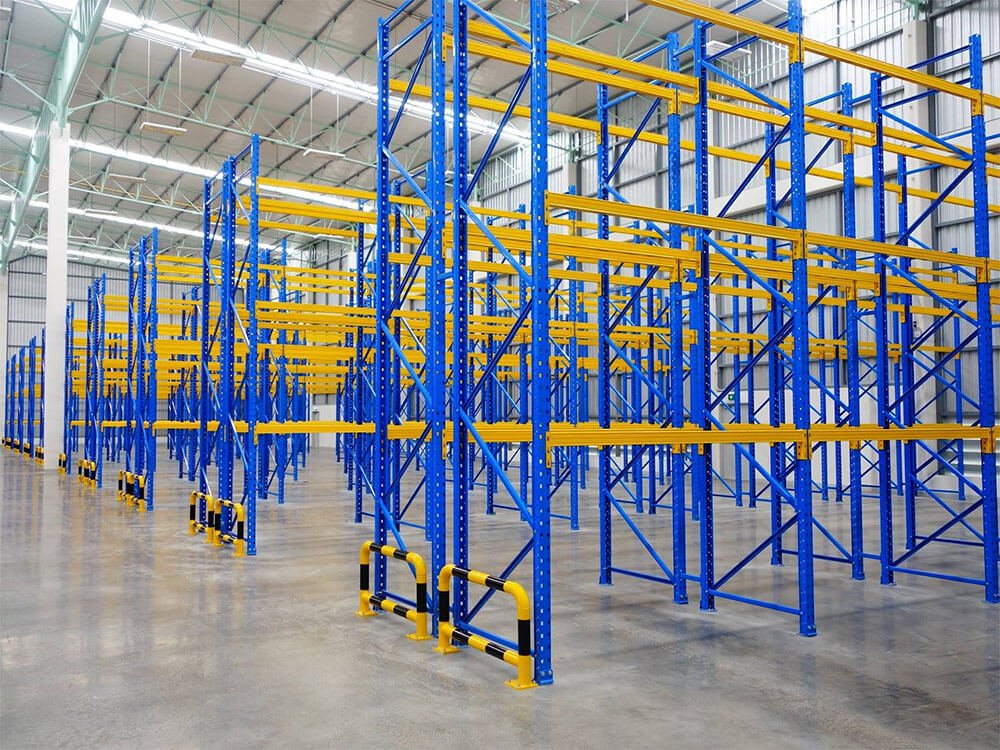

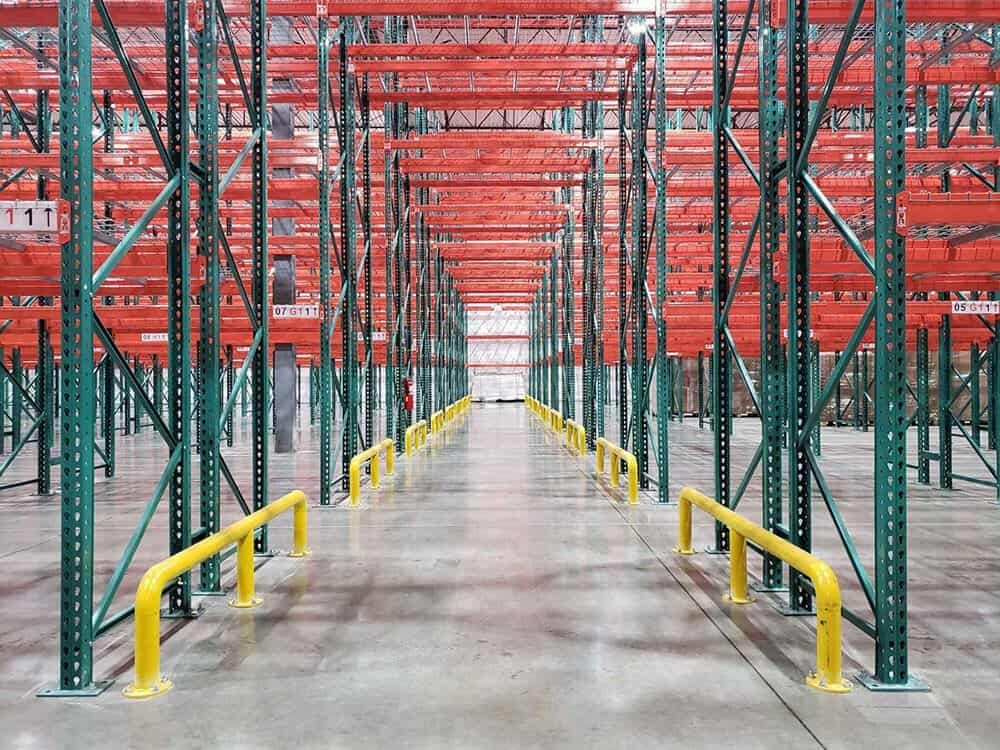

Deciding to buy warehouse racking? It’s a paramount task, without a question! But it’s also a game changer for organizations looking to improve their storage and streamline operations. A properly planned and executed racking system can improve your warehouse by increasing space utilization, enhancing inventory management, and speeding order fulfillment operations.

But that process can be challenging, with various solutions available, each with its own set of benefits and pricing ranges. Besides understanding the differences between various kinds, such as selective pallet racking, drive-in, pushback, and cantilever racking systems, it’s also critical to know other key considerations (load capacity, size, material, and budget) when picking the best match for your individual requirements.

This thorough article seeks to simplify the purchase process for warehouse racking, providing you with important insights and experienced guidance to help you negotiate the market’s intricacies. You’ll go over the most important factors to consider before making a purchase and explore the differences between buying from China versus other nations.

Things To Note Before You Buy Warehouse Racking

Before commencing on the exciting path of purchasing warehouse racking, it’s essential to establish a solid base by carefully examining many vital criteria. This proactive strategy will guarantee that your investment meets your precise requirements, budget, and operational objectives.

Assessing Your Warehouse Space

The first stage you should do to buy racking is comprehensively evaluating your warehouse space. Start by measuring the available floor space, taking into consideration any columns, impediments, or existing fixtures. Don’t forget about the ceiling height, which will limit the maximum height of your racking system.

Next, examine your warehouse’s layout and traffic flow. Determine which places are most suited for racking installation, taking into account aspects like proximity to loading docks, forklift accessibility, and overall warehouse workflow.

Furthermore, assess the floor’s condition and load-bearing capabilities. Ensure that the floor is level and physically solid enough to handle the weight of the racking system and stored items. If required, engage a structural engineer to determine the floor’s load-bearing capability and propose any necessary reinforcements.

Finally, design your perfect warehouse plan with the racking system in place. Consider aisle width, storage density, and accessibility for picking and replenishment activities. This will help you identify the best size and layout for your racking system.

Understanding Your Financial Situation

Setting a reasonable budget is an important stage in the warehouse racking purchasing process. Begin by investigating the typical cost of various racking systems, taking in account material, size, and features. Obtain quotations from many racking providers to get a better idea of market rates.

Then, consider extra expenditures beyond the racking system itself. This covers expenses for installation, permits, and any future expansions. It’s also crucial to think about the continuing expenditures on maintenance and repairs.

Be realistic about your budget and prioritize your demands appropriately. If you have a restricted budget, give secondhand or reconditioned racking systems a try. These alternatives can save you a lot of money while maintaining quality and performance. But before making the purchase, be sure to properly check it for indications of damage.

Identifying Your Specific Racking Needs

Without this step, all above practices will become meaningless. Make sure to thoroughly understand your individual racking requirements by considering the items you keep, their size, weight, and other specific storage needs, such as temperature control or fire resistance.

This healthy practice also helps you assess your present storage issues and find opportunities for improvement. Do you have challenges with space utilization, inventory management, or order fulfillment efficiency? Addressing these pain points will enable you to choose a well-suited racking system for your inventory facility.

But that’s not all! You should also factor in your long-term development goals. Will your inventory grow over the next few years? Do you expect changes in your product mix or storage requirements? If the answer is yes, try to pick a versatile racking system to save you the time and money of replacing or updating your system prematurely.

Finally, prioritize the features that are critical to your operations. This includes essential traits like adaptability to accommodate varying pallet sizes, mobility for quick reconfiguration, or specialized attachments for certain product kinds.

What To Consider When Buying Pallet Racking

After addressing your warehouse space and budget, it’s time to dive into the details of purchasing pallet racking. This section will go over three vital factors that allow you to make an educated selection.

New VS. Used Pallet Racking

The decision between new and old pallet racking is a real challenge for many warehouse operators. While new racking systems offer excellent condition, manufacturer warranties, and cutting-edge design features, it typically has a higher price tag than used choices.

Used pallet racking, on the other hand, is a more affordable option, particularly for organizations with limited resources. But it’s critical to properly check old racks for any indications of corrosion or wear and tear, since weakened structural integrity can endanger warehouse safety.

Where To Buy Pallet Racking

When it comes to purchasing pallet racking, there are many channels you can browse. Let’s explore each type’s pros and cons below:

- Manufacturers: Purchasing directly from manufacturers often results in more competitive prices and customization choices. But the drawback is that you’ll have to deal with higher minimum order quantities and longer lead times.

- Distributors: These facilities serve as mediators between producers and end customers, thereby providing a broader range of brands and goods. They also provide essential design and installation advice. However, their costs can be somewhat higher than direct purchases from manufacturers.

- Online retailers: Did you know that you can buy pallet racking online nowadays? These online retailers offer convenience and a plethora of pallet racking types. They not only provide you with more reasonable costs but also have the capability to ship pallet racks straight to your warehouse. Yet, beware of scams by checking the retailer’s reputation before making the buying decisions.

- Used equipment dealers: They specialize in selling pre-owned pallet racking. Despite being an appealing option for organizations looking to save costs, it’s critical to properly evaluate the racks for quality and safety when purchasing.

Understanding Pallet Racking Prices

If you’re a detailed person, you can easily pick up that there are a lot of variables influencing the pallet racking prices. So, let’s satisfy your mind by delving into some of the top factors below:

- Racking materials: Steel is obviously the most popular material for pallet racking thanks to its strength and durability. But the quality and thickness of steel have a substantial effect on its cost. Lower-grade steel is often more cost-effective but it’s clearly unsuitable for holding large weights. In contrast, high-strength steel has the highest weight capability but is more expensive.

- Size and configuration: The size and layout of your racking system have a direct influence on its price tag. Taller and larger racks with more storage tiers will always cost more than smaller, simpler versions.

- Racking manufacturer: Established brands and manufacturers, such as Unarco, Schaefer, and Lista, charge higher costs because of their reputation for quality and dependability. Lesser-known manufacturers can have more affordable storage solutions, but it’s critical to check their product quality and safety certificates.

- Racking quantity purchased: Buying in bulk usually results in savings and cheaper per-unit costs. If you have a big warehouse or expansion plan, you should buy racking at a large quantity to take advantage of possible bulk savings.

- Additional racking features: Features such as seismic design for earthquake-prone locations, powder coating for increased corrosion resistance, and essential racking accessories for certain product types all raise the total cost. Prioritize aspects that are critical to your business, and spend appropriately.

If you want to learn how to buy cheap warehouse racking, you can check out our article.

Buying Pallet Racking From China VS. Other Countries

Though Chinese manufacturers have a reputation for delivering goods at competitive prices, it’s a good practice to weigh the benefits and drawbacks of sourcing from various nations before landing the final decision.

| Criteria | China | Other Countries |

|---|---|---|

| Cost | More affordable due to lower labor costs and economies of scale | Higher due to higher labor costs and smaller production volumes |

| Quality | Varies significantly | Generally consistent |

| Lead Times | Often shorter due to efficient production processes | Typically longer depending on the manufacturer and location |

| Shipping Logistics | Can be more complex and time-consuming | Often simpler and faster for domestic suppliers |

| Tariffs & Regulations | Subject to potential tariffs and import regulations | May not apply or be less stringent for domestic purchases |

Cost Comparison

One of the main advantages of purchasing pallet racking from China is the possibility of cost reductions. China’s manufacturers often offer cheaper pricing owing to reduced labor costs and economies of scale.

For example, a normal selective pallet rack from a Chinese manufacturer may cost between $30 and $50 per pallet slot, but an equivalent rack from a US manufacturer may cost $80-120 or more.

Kindly note that these are just estimates, and the actual costs can vary greatly based on the individual product, materials utilized, and source. Furthermore, the reduced initial cost of Chinese racking may be countered by extra costs like shipping, import tariffs, and other quality control difficulties.

Quality Consideration

When selecting to buy pallet racking, quality is of the utmost importance since it directly affects the safety and durability of your storage system. While Chinese manufacturers have made tremendous gains in improving product quality, quality standards may nevertheless differ from those of other nations.

Some Chinese manufacturers follow tight quality control procedures and get certifications from foreign organizations such as ISO or RMI, ensuring that their goods exceed worldwide safety requirements.

Nevertheless, before making a purchase, it is critical to study and check a possible supplier’s reputation and qualifications. You can do this simple task by visiting their homepages. If feasible, reach out to them to request samples or visit the production location to evaluate the quality firsthand.

Lead Times And Shipping Logistics

Lead times, or the time it takes to make and ship your purchase, might vary greatly depending on the nation of origin. Chinese manufacturers often have shorter lead times owing to their efficient manufacturing processes and established supplier systems.

But, unless your warehouse is in China, shipping from China can take longer and require more sophisticated logistics than ordering from a local provider.

So, when planning your order, be sure to consider lead times and delivery complications. If you have a tight deadline or need a rapid turnaround, procuring from a local provider is undoubtedly the best alternative, even if it means paying a little higher price.

Potential Tariffs And Import Regulations

When purchasing pallet racking from China or other countries, you should be aware of any tariffs and import rules that impact the entire expenditure. Tariffs are taxes levied on imported products that vary according to the product category, country of origin, and current trade policy.

Import laws, such as those that require special paperwork, certificates, or inspections, may often be difficult to navigate. To minimize unexpected delays or charges, investigate and understand the applicable customs and rules for your transaction.

Pallet Racking Buying Process: A Step-By-Step Guide

Navigating the pallet racking purchasing process is certainly challenging. But with a methodical approach and careful study, you can make a successful deal that maximizes your warehouse’s storage capacity and operating efficiency.

#1: Defining Your Storage Needs

The first stage in the purchase process is to carefully define your storage needs. This goes beyond analyzing the various traits of your stored products. You should also evaluate your present storage difficulties and find ways to rectify the situations.

Do you have challenges with space usage, inventory management, or order fulfillment efficiency? Clearly outlining your pain points will drive your decision-making process and guarantee that the racking system you choose meets your unique requirements.

#2: Researching And Comparing Suppliers

Once you’ve established a thorough understanding of your inventory demands, it’s time to study and evaluate several pallet racking vendors. Look for reliable manufacturers or wholesalers with a track record of producing high-quality items and providing outstanding customer service.

Here’s a small tip: always get quotations from various vendors and compare pricing, product details, guarantees, and lead times. Most people don’t want to go down this path as the more vendors you reach out to, the more work and thinking you have to put in, making it harder to finalize a selection.

But the paradox of choice doesn’t apply here. Carefully evaluating multiple suppliers may require more time but once it’s done properly, you won’t have to worry about this project for years. So, don’t be afraid to ask questions about their experience, skills, and any other services they provide, such as design consulting or installation support.

#3: Requesting Consultations And Site Visits

Working with a pallet racking professional or consultant is a really wise move that benefits your purchasing process. Typically, you can request this consultation service with the vendors you’re working with. They can evaluate your warehouse architecture, storage demands, and operating requirements before recommending appropriate racking solutions.

In addition, after narrowing down the supplier number, ask for site visits so that they can understand your facility’s actual circumstances better. This really helps in later stages, avoiding errors in design and installation.

#4: Reviewing And Finalizing The Proposal

After obtaining quotations from many providers, thoroughly analyze each one to verify it meets your specific requirements and budget. Compare the proposed racking system’s specs, such as load capacity, size, material, and any optional features.

Also, pay special attention to the proposal’s terms and conditions, which include warranties, payment terms, and delivery timelines. Don’t be afraid to bargain with vendors to obtain the best possible offer.

#5: Placing Your Order And Scheduling Installation

Once you’ve approved the idea and everyone is on the same page, it’s time to make it official: place that order! This is where the rubber meets the road, so confirm delivery dates with your supplier and ensure your warehouse is ready for a makeover.

Don’t worry if you’re not good at assembling furniture! Most providers offer expert installation services. It may be an additional expenditure, but it is worthwhile to ensure that your racking system is constructed to survive and does not collapse like a Jenga tower.

#6: Inspecting And Accepting Racking Systems

After installation, carefully inspect the racking system to ensure it meets your expectations and complies with safety laws. Check for any damage, missing components, or installation errors.

If you discover any problems, tell the provider immediately and urge remedial action. Once you are pleased with the installation, sign off on the racking system’s approval.

Insider Tips For Buying Warehouse Racking

Aside from the basic elements of the purchase process, here are some insider ideas to help you understand the complexity of warehouse racking and get the greatest value for your money.

Negotiating Prices And Terms

Don’t be afraid to haggle with providers to obtain the most value for your money! Pallet racking is a competitive industry, therefore providers are often prepared to sweeten the sale by offering discounts or other bonuses to entice you.

Do your homework in advance to see what rates are available. Then, negotiate to get the best deals on price per pallet location, shipping fees, and even installation expenses. Remember that every cent counts!

Besides prices, also discuss payment plans, warranties, and the kind of assistance you’ll get after you purchase. Be confident and assertive in your talks, and you’ll be astonished at the kind of discounts you can get! It’s like receiving a free present with your purchase; everyone enjoys that!

Assessing Financing Options

Don’t worry if purchasing your desired warehouse racking system all at once isn’t an option right now. There are other methods to get your hands on that awesome storage arrangement. Leasing is similar to renting a nice property in that you get to enjoy all of the benefits without the high upfront payment. It’s an excellent choice for startups or enterprises who want to stay within their budget.

A bank loan or line of credit is another option for financing the racking system. Just make sure you read the fine print and understand the interest rates before signing the dotted line. Finally, it comes down to selecting a finance plan that is a good fit for your organization.

Prioritizing Safety And Compliance

When purchasing warehouse racking, be sure it’s made to last and won’t crack like a biscuit under strain. Look for racks that comply with industry safety requirements such as the RMI/ANSI MH16.1. Consider it a safety mark of approval for your racking system, confirming that it can withstand everything you throw at it (or on it, in this instance!)

Before you begin stacking those racks sky high, ensure that you have authorization from the authorities. Depending on where your warehouse is situated, you may need permits or inspections to ensure that everything is up to code.

Conclusion

To summarize this buy warehouse racking trip, keep in mind that it’s more than simply purchasing some racks. It’s a huge choice that will determine whether your warehouse succeeds or fails. You’re preparing for a big storage update by taking the time to determine your requirements, budget, and possibilities.

Choosing the appropriate racking system is like finding the ideal jigsaw piece: it must fit perfectly. Take a close look at your warehouse space, figure out what you’ll be keeping, and don’t forget to budget. Once you’ve determined those facts, it’s time to consider your alternatives. Thanks for reading!