Storing lumber can be difficult. Wood often ends up piling up, risking damage and providing a challenge to get to them when one really needs to. This disorganized setup takes up too much time and space and drives you nuts. Cantilever lumber racks are the perfect solution. These racks are specifically designed to store long, heavy materials such as lumber. They make the most of space, increase your office’s accessibility, and safeguard your inventory. This article will teach you about the different types of cantilever racks and their most important features and how to choose the ideal one for what you need. Say ‘farewell’ to storage headaches and ‘welcome’ to a more organized lumber management process!

What Is a Cantilever Lumber Rack?

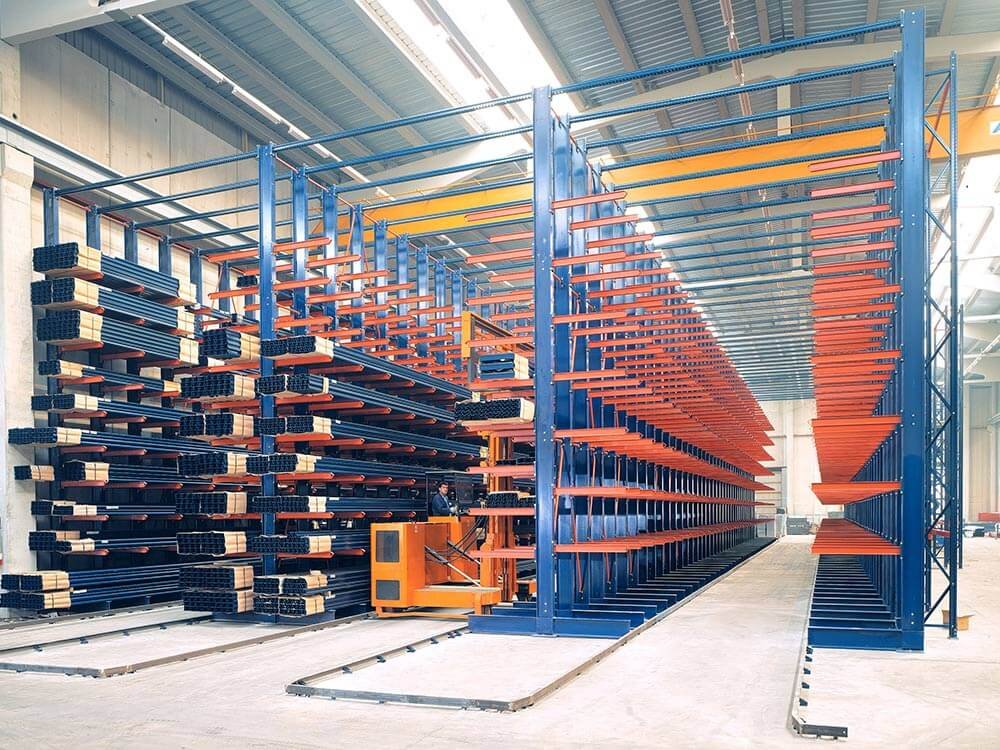

A cantilever lumber rack is also known as a lumber rack or a lumber storage system, which is intended for long and bulky items like lumber, pipes, and steel. This has a base for stability, uprights for vertical support, and arms that extend out to hold material. They come in varying sizes and configurations to fit your storage needs. The forklifts or simple man handling can easily load and unload the design. The rack comes with adjustable arms allowing you to customize the rack for different lengths and weights of materials. This versatility helps you make the most of the space and organize your inventory effectively. A durable, reliable storage solution for heavy, irregularly shaped items.

Major Types of Cantilever Lumber Racks

1. Cantilever Racking Systems for Light-duty Applications

In retail or workshop settings they are perfect for lighter loads such as pipes, furniture or small lumber. Upright columns made of light-gauge steel and sturdy arms for versatile storage. They are very affordable, relatively easy to assemble, and perfect for organizing lighter materials. Their compact design saves space and keeps everything readily accessible.

2. Structural/Heavy Duty Cantilever Racking Systems

Heavy duty cantilever racks are designed for industrial use, handling heavy loads with ease. They are made out of structural steel, and are therefore very durable and strong. You can use them to store oversized, bulky, or heavy items safely. They are designed for outdoor conditions to function over the long term. They are reliable in demanding applications because of their high load bearing capacity.

3. I-Beam Cantilever Racks

These racks maximize load support using I-beam arms providing double sided storage. The racks use space efficiently and can handle loads of up to 20,000 pounds. They are better for storing dense or oddly shaped items. They have robust design that guarantees stability and flexibility in positioning heavy items.

4. Roll Formed Arms Cantilever Racks

These racks are a great option for medium duty storage if you are looking for a cost effective solution. Roll formed steel arms provide reliable support for moderate loads and are relatively easy to assemble. For applications that prioritise affordability and functionality, these racks are ideal. Lightweight construction ensures simple handling without compromising on durability.

5. Structural Steel Arms Cantilever Racks

Structural steel arms offer unmatched strength for their respective load capacity. Designed for industrial environments with high durability, these racks are built. They can be used to secure extremely heavy, oversized items. They are a premium choice due to their robust construction for demanding storage needs and long lasting performance.

Choosing the Right Cantilever Lumber Rack

Choosing the right cantilever lumber rack is essential for effective storage and organization. The right rack will enable you to safely store lumber, exploit more space, and facilitate material access.

Factors to Consider

Assess load capacity before anything else. Determine the weight and volume of lumber you intend on storing. Find a rack that can take on your heaviest loads safely. Second, analyze your space to determine how much you have. Make sure your rack fits in your storage area, but also that there is plenty of room for easy access. Decide if your rack will be used for indoor or outdoor storage. Galvanized steel provides the weather resistant materials needed for the outdoor racks.

Cantilever Lumber Racks for Sale Comparison

Materials, like steel or aluminum, are used for different racks with unique benefits. Steel is heavy duty and good for use with the heavy equipment, and aluminum is lightweight and resistant to corrosion. Compare prices and quality. There are budget friendly options but if you invest in a high quality rack you are more likely to have fewer replacements over time.

Cantilever Lumber Rack Plans Importance

Optimization of installation and long term functionality requires detailed plans. Planning properly will result in your rack keeping up with current needs but allowing for future growth. Make sure the options you’re looking at provide customizable plans for your particular storage needs.

Customization Options

Rack utility is enhanced via customization. Obtaining adjustable arms and uprights to store lumber of varying sizes. Perfect for optional accessories such as dividers for better organization or safety stops to prevent accidents in loading and unloading.

Manufacturer Reputation

Pick a cantilever rack manufacturer with positive customer reviews and a solid track record. Look for suppliers with warranties and good customer service. All these add to peace of mind and help in the case of any hiccup.

Cantilever Rack For Lumber Installation and Maintenance

Installation Process

Start assembling your cantilever lumber rack step by step. Bolts or anchoring to secure the base to the floor or a stable surface. Attach the uprights to the base properly aligned. Fasten the arms to the uprights with brackets or fasteners for stability. Make sure everything is tight and nothing is moving. Accurate setup uses basic tools such as wrenches, screwdrivers, and measuring tape. To ensure there isn’t an error, double check the assembly instructions.

Safety Considerations

Make sure the rack is placed on a level surface for stability. Tighten it securely, so that it won’t tip over. Make sure to adhere to the manufacturer’s weight limits and spread the load out evenly across the arms. Avoid overloading because it can compromise the structure. Heavier items at the bottom lend an extra degree of stability.

Routine Maintenance

Regularly inspect your rack for signs of wear, such as loose bolts and bent arms. Prevent dust and debris build up in your structure. Protective coatings are applied to protect against rust and extend life.

Upgrading or expanding the Rack.

As your needs grow, add arms or uprights to increase capacity. To increase functionality, install modern accessories such as safety stops or adjustable arms.

Addressing Common Issues

Rust or corrosion can be treated with rust resistant paint. Have bent or damaged parts replaced promptly. It is maintained with regular care and remains long-lasting.

Applications of Cantilever Lumber Racking

Used in Warehouses and Industrial Facilities

By using cantilever lumber racks you will be able to streamline material handling and improve organization. Second, their open design makes them ideal for storing longer or bulkier items, such as timber, pipes or sheet goods. These racks are used by businesses to pack as many items onto one rack as possible and quickly locate the items needed. With such a setup, downtime can be minimized and productivity increased.

Outdoor Lumber Yards

For outdoor lumber storage, cantilever racks are ideal. With their sturdy construction, wood is kept off the ground and away from rot or warping. Extra protection from rain and UV damage is provided by roofed cantilever racks. This helps ensure product quality and waste from environmental exposure.

DIY and Small-Scale Usage

For personal or small business needs, you can make cantilever racks. Custom racks can also be built using the DIY plans using basic tools and materials. It does save money and fits your exact space requirements. These racks are great for small scale use, keeping your work area organised and clutter free.

Retail Applications

Hardware and home improvement stores use cantilever racks to create better lumber displays. Customers find them convenient to use as they do not have to select or browse for the material. The improved visibility and accessibility contributed to improving a better shopping experience which, in turn, promotes sales.

Construction Sites

Cantilever racks are used on construction sites for temporary storage of lumber and other materials. In dynamic environments, they keep supplies organized and easy to access. These racks help you stay on schedule by reducing material handling time.

Benefits of Using Cantilever Racks for Lumber

Improved Storage Efficiency

Cantilever racks enable you to make full use of both vertical and horizontal space. It enables you to store long or bulky lumber without adding to the clutter. Compared to traditional shelving, these racks present open access for organizing and retrieving materials. Even in small storage areas you manage to fit in every inch of space efficiently.

Cost-Effectiveness

In the long run, they can help you save money. This makes them more durable which leads to less replacements and lower maintenance costs. Switching to a business from normal storage often results in reduced time and labor expenditure. You have faster handling and less material damage resulting in lower overall operating costs.

Enhanced Accessibility

Cantilever racks have an open design that makes it easy to start handling and accessing lumber. You don’t need to waste any time maneuvering through tight spaces or trying to reach difficult materials. It increases productivity and takes some of the physical strain off workers. It frees up bandwidth for your team to focus on more important tasks.

Flexibility in Storage Design

They adapt to your needs with their cantilever racks. By modifying or reconfiguring them, you can adjust how you store different sizes and types of lumber. They support your business as it grows or changes because they are versatile.

Durability and Longevity

These racks are built with high strength materials to lift heavy loads without effort. They are resistant to wear, tear and environmental damage resulting in many years of reliable use. You’ll get a lasting solution that consistently performs.

Frequently Asked Questions about Lumber Cantilever Racking

How much does a cantilever lumber rack typically cost?

Cantilever lumber racks cost can depend on factors like material, size, and design. Between $200 and $600, you should expect a basic model. Prices can start at $1,500 or higher for heavy duty versions with custom features. The type of material used—most often steel—has a large effect on the price.

Can Cantilever Lumber Storage Racks Be Customized?

Yes, in most cases manufacturers do offer customization options. The rack size, weight capacity, and number of arms are all adjustable so you can tailor the rack to fit what you need. Customization helps you ensure the rack fits your available space and storage requirements.

Is it possible to find Cantilever Lumber Racks for Sale?

If you are interested in cantilever lumber racks, you can check versions from your local hardware store, from an industrial supplier or from an online platform like Amazon or Rackmen. You must check out the options and get the best deal based on your requirements. But I suggest you take a look at Lrarking, as a cantilever lumber rack manufacturer from China, our products are usually better value for money while ensuring quality.

Conclusion

Cantilever lumber racks provide efficient storage for long, bulky materials in minimal space. These systems come with various types, such as light-duty, heavy-duty and I-beam racks that give flexibility, durability and better accessibility. These are great for out door yards, construction sites, warehouses and DIY projects. Determining which rack type to go with comes down to your load capacity, amount of space available and your intended use. But regularly maintaining the engine also ensures longevity and reliable performance. Browse through available cantilever racks for lumber for sale and choose the best solution that suits your storage and organization needs. And now you can start optimizing your storage space!