China Double Deep Pallet Racking System Manufacturer

What Is Double Deep Pallet Racking

Double Deep Pallet Racking is a racking storage system derived from selective pallet racking, where pallets are stored on both sides of each aisle, one in front of the other. Double-deep pallet racking reduces the number of aisles compared to single-deep pallet racking systems, and this configuration allows for higher storage densities. It is suitable for warehouses that wish to maximize storage capacity while maintaining selectivity. As the number of goods on the racking depth exceeds two pallets, ordinary forklifts are no longer able to complete the access to the goods on the double-deep pallet racking, and special double-deep forklifts equipped with telescopic forks are required for accessing the goods.

Customizable Double Deep Racking Dimensions

Due to the varying sizes of warehouses and storage requirements among different clients, double-deep pallet racking is typically customized. However, based on our experience, we recommend some standard sizes of double-deep pallet racking for your reference.

| Size(mm) | Color | Layer | Load Capacity |

|---|---|---|---|

| L2300*D800*H4000 | Orange | 5 layer | 1000kg/layer |

| L2500*D1000*H5000 | Blue | 5 layer | 1500kg/layer |

| L2700*D1000*H5000 | Black | 5 layer | 2000kg/layer |

| Customizable | Customizable | Customizable | Customizable |

Double Deep Pallet Racking Design

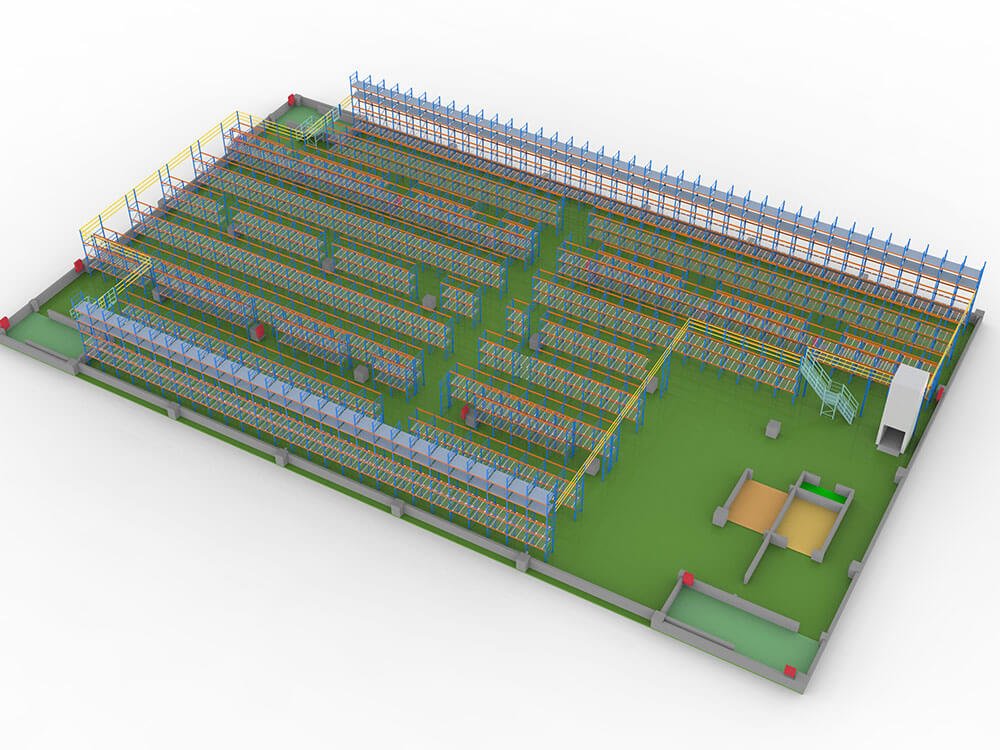

Double Deep Racking Layout Design

Please send us detailed data such as warehouse size, cargo size, etc. Our engineers will design a reasonable layout plan for you.

Three-dimensional drawing of Double Deep Racking

The exact dimensions of the racks, the load and the number of tiers will be presented to you in a three-dimensional drawing.

Rendering of Double Deep Racking

If the project is complex, we can also produce installation drawings for you, and we can even produce renderings if necessary.

Why Choose Lracking Custom Double Deep Racking System

1. Expertise and experience: Lracking has many years of experience in manufacturing double deep racking systems and is able to design and customize double deep racking solutions for specific warehouse needs.

2. Quality Assurance: Lracking’s adherence to international standards and certifications, with specialized industry certifications such as ISO9001, CE, TUV, and AS4084, ensures the quality of its products and the delivery of durable and reliable racking systems.

3. Customization Options: Lracking offers customizable options to fit various warehouse layouts and storage requirements, providing flexibility in design and configuration.

4. Cost Effectiveness: China is synonymous with good value for money, and as one of the top three manufacturers of double-deep racking in China, Lracking can help optimize warehouse space utilization while minimizing costs by offering competitively priced and efficient solutions.

5. Customer Support: Lracking provides excellent customer support, assisting customers from pallet racking design to racking installation, ensuring a smooth and hassle-free experience.

Application of Double Deep Pallet Racking System

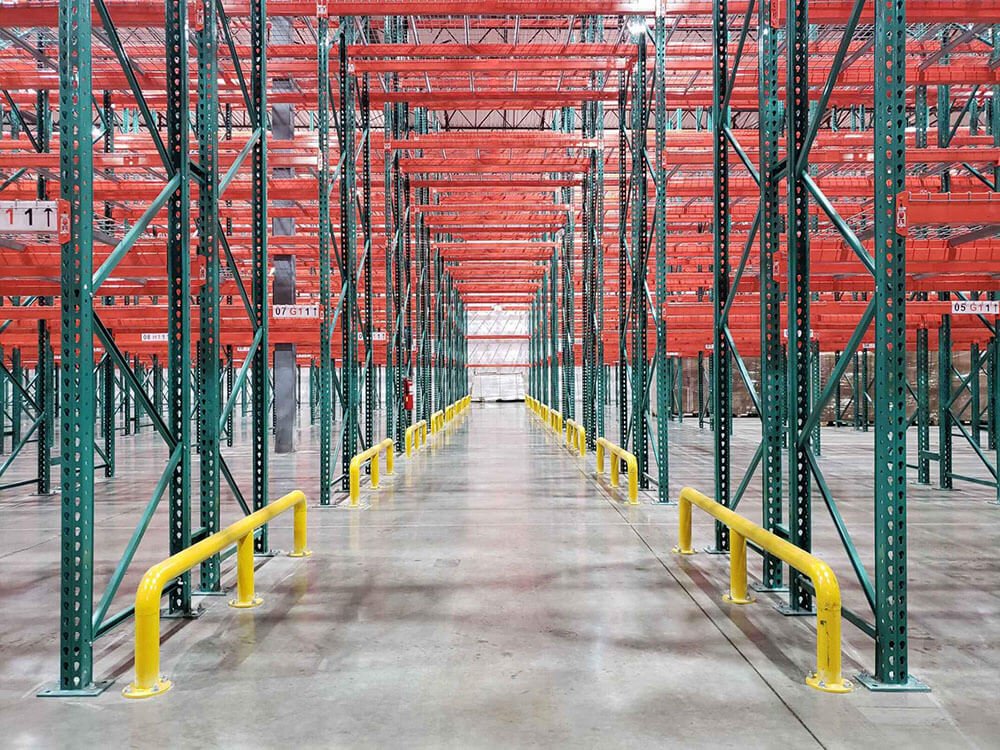

double deep racking for warehouses

Double deep racking is a space-saving solution ideal for warehouses looking to maximize storage capacity while maintaining accessibility. Storing pallets two deep reduces aisle space and increases storage density. This setup requires specialized double-deep forklifts with extended reach capabilities to access rear pallets. It’s suitable for warehouses with a high volume of palletized goods and a need for efficient use of space. Double deep racking offers cost-effective storage solutions for warehouses with limited floor space and a desire to optimize storage efficiency.

Double-deep racking for high-density storage

Double-deep racking is an efficient solution for high-density storage needs in warehouses. By storing pallets two deep, it maximizes the use of available space while still allowing access to each pallet. This setup is particularly beneficial for warehouses with limited floor space but a high volume of inventory. With double-deep racking, pallets are stored in pairs, which increases storage density without compromising accessibility. This configuration is ideal for warehouses looking to optimize their storage capacity while maintaining efficient retrieval of goods.

Double-deep racking for bulk storage

Double-deep racking is an excellent choice for bulk storage needs in warehouses. By allowing pallets to be stored two deep, it efficiently utilizes available space while providing easy access to inventory. This configuration is ideal for storing large quantities of similar items, such as bulk goods or oversized items. With double-deep racking, warehouses can maximize their storage capacity without sacrificing accessibility or efficiency.

Frequently Asked Questions About Double Deep Pallet Racking

How much does a double deep pallet rack cost?

The cost of double deep pallet racking varies depending on the size of the project, load capacity, number of shelves, and other factors. On average, double-deep pallet racking costs between $100 and $200 per pallet location. In fact, double-deep racking is a derivative of selective pallet racking, and it costs roughly the same as selective pallet racking. It’s just that double-deep racking requires an additional double-deep forklift, which can add to the cost. However, to get an accurate cost estimate, it’s best to consult with a double-deep racking supplier with specific details about your storage needs.

How do double deep pallet racks work?

Double Deep Pallet Racking works by storing pallets in two depths, with one pallet in each aisle behind the other. No aisles are required between the two storage racks and only minimal safety clearance is needed. Pallets are accessed from the rear position through the use of a double-depth forklift. This configuration reduces the number of aisles from four to two, increasing storage density but reducing rear pallet accessibility. Selecting double-deep racking requires careful planning and coordination to ensure efficient stock rotation and access to goods.

What is the difference between double deep pallet racking and selective pallet racking?

The main difference between double deep pallet racking and selective pallet racking is storage capacity and selectivity. Double deep pallet racking can store two pallets back to back, compared to selective pallet racking where only one pallet can be stored between each pallet, effectively doubling the storage density. However, this increase in density comes at the expense of selectivity, as double-deep pallet racking requires specialized equipment, such as a double-deep forklift, to access the pallets stored deep in the rack. Selective pallet racking provides easier access to individual pallets than double-deep racking, but at a lower storage density.

What is the load capacity of the double deep pallet rack?

The load capacity of double deep pallet racking depends on a variety of factors, including rack design, material specifications and more. Typically, double deep pallet racking is designed to support heavy loads, with load capacities ranging from 1,000 to 3,000 kilograms per pallet position and higher. However, it is important to consult with the double deep pallet racking manufacturer to determine the exact load capacity of double deep pallet racking based on your actual storage needs and the configuration of your racking system.

Are the double deep pallet racks easy to install?

Double deep pallet racking is simpler to install because of its simpler composition, consisting mainly of upright frames, beams and connecting rods. However, double deep pallet racking typically requires more installation time and expertise than standard pallet racking systems, as they have deeper configurations that require precise alignment. Proper installation ensures the stability and safety of the racking system, as well as optimal utilization of warehouse space.

What is the MOQ for Double Deep Pallet Racking?

Generally speaking, we do not set a minimum order quantity for double-deep pallet racking. We can offer maximum flexibility based on the actual needs of our customers. Since double deep pallet racking is all customized and double deep pallet racking needs to be used in conjunction with double deep forklifts, only by ordering in large quantities can we reduce the cost in a comprehensive manner.