China Drive In Drive Through Pallet Racking System Manufacturer

What Is Drive In Drive Through Pallet Racking

Drive-in and drive-through pallet racking systems are storage configurations designed for high-density storage of palletized goods. In drive-in racking, pallets are stored on horizontal rails without aisles, allowing forklifts to drive directly into the rack system. The last-in pallet is usually the first one that can be retrieved, following a Last-in, First Out (LIFO) storage method. Drive-through racking is similar but features entry and exit points on both sides, creating a continuous aisle. This system allows for greater selectivity in accessing pallets, accommodating both Last In, First Out (LIFO) and First In, First Out (FIFO) storage methods.

Customizable Drive In Racking Specifications

Customized drive-in racking is designed to meet specific warehouse requirements, optimizing storage for high-density pallets. Features can include tailored dimensions to accommodate varying load sizes, configurations to suit specific forklift types, and adjustments to align with the unique storage needs of the products. The customization ensures efficient use of space, improves accessibility, and enhances overall warehouse functionality.

| Size(mm) | Color | Layer | Load Capacity |

|---|---|---|---|

| L1550*D1250*H3000 | Orange | 4 layer | 1000kg/layer |

| L1550*D1250*H4000 | Blue | 5 layer | 1500kg/layer |

| L1550*D1250*H5000 | Green | 6 layer | 2000kg/layer |

| Customizable | Customizable | Customizable | Customizable |

Drive In Drive Through Racking System Design

Drive In Racking Layout Design

Please send us detailed data such as warehouse size, cargo size, etc. Our engineers will design a reasonable layout plan for you.

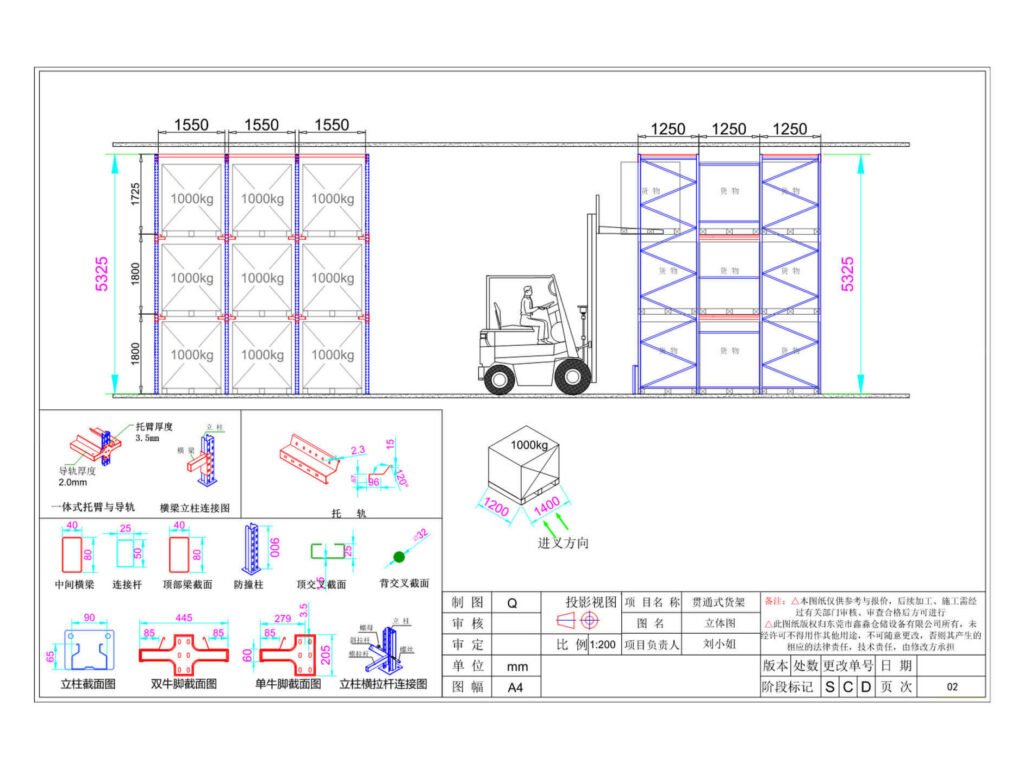

Three-dimensional drawing of drive in racking

The exact dimensions of the racks, the load and the number of tiers will be presented to you in a three-dimensional drawing.

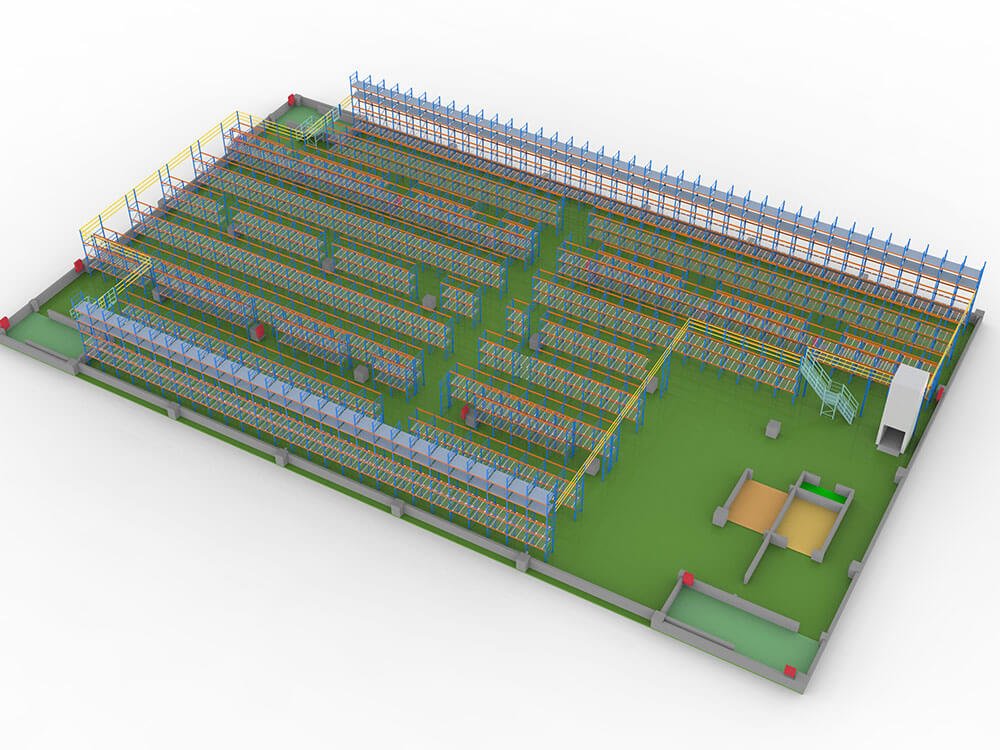

Rendering of Drive In Racking

If the project is complex, we can also produce installation drawings for you, and we can even produce renderings if necessary.

Why Choose Lracking Custom Drive In Drive Through Pallet Racking

Choosing Lracking for custom drive-in pallet racking offers several advantages:

Firstly, as one of China’s top ten manufacturers of drive-in racks with over sixteen years of manufacturing experience, Lracking ensures optimal space utilization when designing customized drive-in rack solutions.

Secondly, Lracking holds certifications such as ISO9001, CE, AS4084, and TUV, guaranteeing product durability and safety, with quality that meets industry standards.

Lastly, it’s worth noting that Lracking is located in Dongguan, the world’s manufacturing hub. Chinese-manufactured products are known for their excellent value, and purchasing drive-in racks from China undoubtedly helps to significantly reduce costs.

Application of Drive In Drive Through Racking System

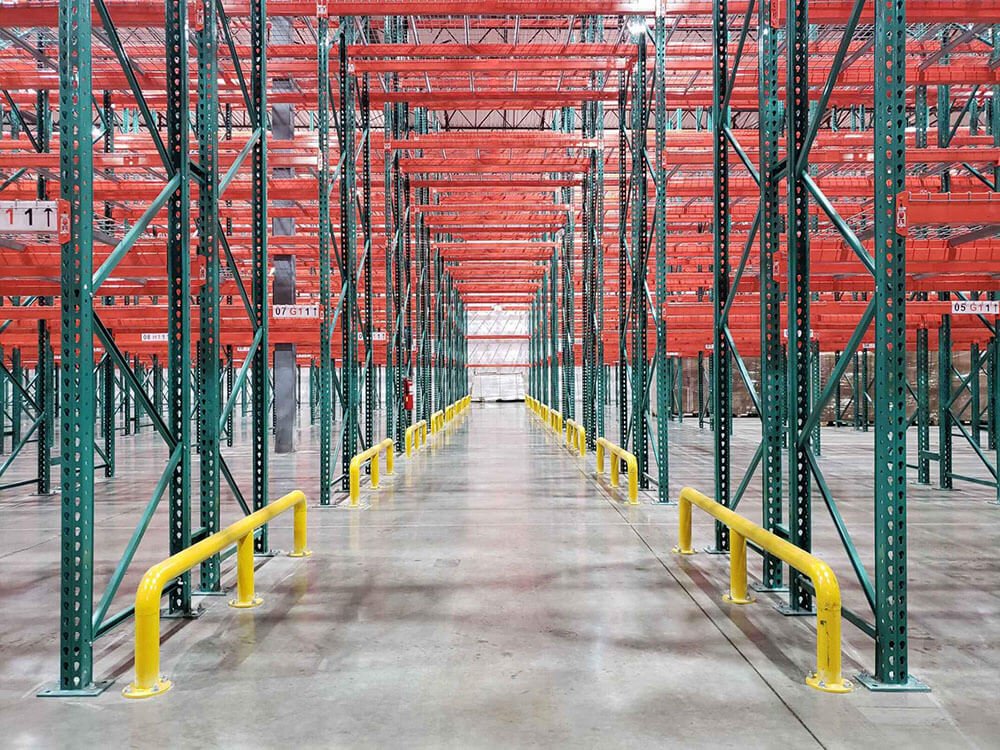

drive in high density racking

Drive-in racking maximizes storage capacity by eliminating aisles between shelves, making it a high-density rack that maximizes the use of available space. It also allows for storing large volumes of similar products and provides easy access to pallets stored in the system. Additionally, drive-in racking systems are cost-effective compared to other high-density storage solutions, making them a practical choice for warehouses with limited space.

warehouse storage drive in racking

Drive-in pallet racks are an ideal solution for warehouse storage, especially in environments where space optimization is crucial. By eliminating aisles between racks, these systems maximize storage density, allowing for the efficient storage of large quantities of palletized goods. With the ability to store multiple pallets of similar products, drive-in pallet racks facilitate easy access and retrieval, making them suitable for warehouses with high throughput requirements.

cold storage racking

Drive-in racking, as a high-density storage solution, is highly suitable for preserving perishable goods and maintaining consistent temperatures throughout the storage area, making it commonly used as cold storage racking. Additionally, drive-in racking offers flexibility in inventory management, supporting both First-In, First-Out (FIFO) and Last-In, First-Out (LIFO) storage configurations. Its durable construction, often using galvanized steel, ensures reliability in harsh cold storage environments while reducing overall footprint and operational costs.

Frequently Asked Questions About Drive In Drive Through Pallet Racking

How does drive-in pallet racking work?

Drive-in pallet racking works by eliminating aisles similar to those between selective pallet racks, allowing forklifts to drive directly inside the racking structure to load and retrieve pallets. Pallets are stored on horizontal rails within the racking, with each level supporting multiple pallets. This high-density storage system maximizes space utilization by eliminating aisles and stacking pallets close together.

What is the load capacity of the drive-in pallet rack?

The load capacity of drive-in pallet racking depends on a variety of factors, such as the design of the drive-in racking, the materials used, and the dimensions. Typically, drive-in pallet racking is designed to carry heavy loads, usually between 1,000 and 2,000 kg per pallet. Please consult the drive-in racking manufacturer to determine the exact load capacity for your requirements and application.

What is the cost of drive-in pallet racking?

The cost of drive-in pallet racking varies depending on factors such as size, capacity, materials, design complexity, customization and supplier. In general, standard drive-in racking systems cost between $30 and $50 per storage space. To obtain an accurate cost estimate, it is recommended to contact the Lracking drive-in pallet racking manufacturer directly with specific requirements and specifications for your storage needs.

Are drive in pallet racks easy to install?

Drive-in racking is a relatively simple structure with the main components being the upright frame and rails. Compared to complex racking systems such as ASRS and shuttle pallet racking, drive-in racking is relatively easy to install. However, in order to ensure correct and safe assembly and to reduce safety hazards during use, it is still necessary to have installation personnel with specialized knowledge to carry out the installation.

Can you provide me with a free design for a drive-in pallet racking system?

Of course, our engineers can provide you with free design drawings of drive-in racking and calculate an accurate quotation for you based on the drawings. You need to tell us the dimensions of your warehouse as well as the volume and weight of the goods to be stored, etc. We will make the most reasonable design based on these detailed data to ensure the safety and efficiency of the drive-in racking system. Don’t hesitate to contact Lracking’s engineers for a free drive-in racking design today.

What are the differences between shuttle pallet racking and drive-in pallet racking?

Drive-in racking requires forklifts to physically enter the rack structure to load and retrieve pallets, while shuttle racking utilizes a shuttle system that autonomously moves pallets within the rack. Drive-in racking typically offers last-in, first-out (LIFO) access, while shuttle racking can provide both first-in, first-out (FIFO) and last-in, first-out (LIFO) access depending on the configuration. Shuttle racking is generally faster and more efficient than drive-in racking due to the autonomous shuttle system, allowing for quicker handling of goods.