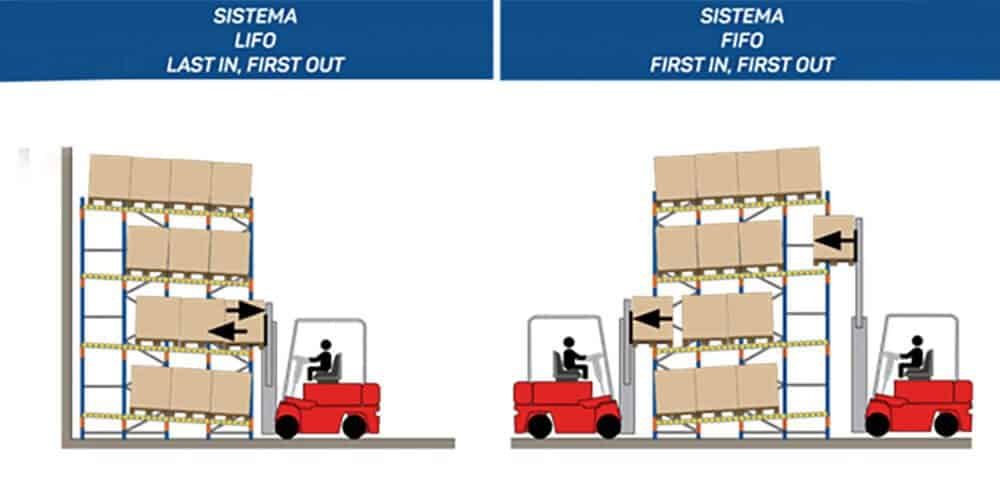

FIFO and LIFO, which stand for “first in, first out” and “last in, first out” respectively, are two terms often found at the heart of inventory management discussions. As the names suggest, these acronyms represent contrasting approaches to how businesses handle their stockpiles of goods.

Selecting a suitable stock rotation between FIFO and LIFO for your warehouse is crucial, as a not-so-good decision can lead to inefficient warehouse performance.

Realizing the importance of such a choice, this article aims to provide a comprehensive comparison between the two stock rotation systems. It will explain thoroughly each concept, compare them, and offer guidance on which system you should consider.

What Is The FIFO Stock Rotation System?

As briefly mentioned above, FIFO stands for “first in, first out” and refers to an inventory management method in which the first product batch entering the warehouse is the first one to be shipped out to stores or directly to customers.

The following sections will elaborate on the pros and cons of this stock rotation system, together with cases and storage systems ideal for its application.

Benefits Of Employing FIFO

Using the FIFO method for your storage facility offers several benefits, some of which include:

- Lowering risk of obsolescence or expiration: Since FIFO makes sure the first unit load coming in will be shipped out first, it minimizes the time products must stay in warehouses, thus lowering the risk of expiration or obsolescence.

- Decreasing inventory costs: Nobody wants to be burdened with high inventory expenses due to dead stocks. With FIFO, that issue won’t trouble anyone anymore, as this stock rotation doesn’t allow items to stay in warehouses for too long.

- Providing flawless inventory turnover: Thanks to the characteristic of releasing the products that have been stored longest first, FIFO offers flawless inventory turnover by sorting products according to their arrival order.

- Preventing product devaluation: There’s a harsh truth that items staying in warehouses for a long time will gradually lose their value. As the FIFO system minimizes inventory duration, it also prevents product devaluation.

- Improving quality control: By consistently selecting the oldest items for fulfilling orders, you can control product quality more easily. This practice ensures the product will always be in good condition when reaching customers, thus lowering the risk of being complained about.

- Reducing warranty claims: Some products have their warranty valid from the manufacturing date. This means the shorter the stock duration is, the better, as then the warranty is still in effect when customers receive the goods. As a result, there will be fewer warranty claims.

Drawbacks Of Employing FIFO

FIFO isn’t and never will be the perfect system. Otherwise, there would be no chance for the existence of other alternatives (such as LIFO, which will be discussed in later parts). Let’s talk about some reasons why some companies refrain from using FIFO.

- Demanding better compliance systems: Consistent execution is the key to the effective large-scale implementation of FIFO. You’ll need some sort of automation and management system to make FIFO a reality.

- Inflexible in certain cases: Despite being ideal for products with expiry dates, FIFO may become too rigid and inflexible in certain situations, such as when the items are about to be expired or outdated. In such cases, some steering and modifications are required.

- Requiring a streamlined product tracking system: When overstock or out-of-stock occur due to rising demands, product tracking with FIFO can be disastrous. Thus, for FIFO to work, you’ll need a good inventory forecast tool and a streamlined tracking system to ensure a consistent product flow.

- In need of more warehouse space (maybe): More space might become a condition for a successful FIFO implementation. This stock management system requires additional areas for the effective rotation of new goods to the back.

Ideal Storage Systems For FIFO

Not all pallet racking types are compatible with the use of the FIFO system due to its unique product flow. For effective FIFO employment, consider installing the following pallet rack varieties:

- Selective pallet racking

- Drive-in pallet racking

- Pallet flow racking

- Satellite pallet racking

- Live pallet racking

- Automated Storage And Retrieval System (AS/RS)

Suitable Application Of FIFO

Whenever you hear the term FIFO, think of perishable goods with an expiration date! FIFO and this product type are a heavenly match, as retrieving what comes into the warehouse first will prevent the item from being spoiled.

Thus, FIFO works best with industries that demand perfect inventory turnover and perishable products with a short shelf life. Some typical examples include food, cosmetics, and pharmaceuticals.

Surprisingly, even fashion and technology companies can employ FIFO, as their products are often trend-based, updated on a daily basis, and can become obsolete in a short time.

What Is The LIFO Stock Rotation System?

In contrast to FIFO, the LIFO (or “last in, first out”) stock rotation system calls for the last product batches coming into the warehouse to be the first units out. Products previously loaded on the pallet racks will remain in the storage facility until all the other units in front of them are shipped out.

Due to the opposite approach, LIFO obviously has different pros and cons. This storage system is also suitable for distinct pallet racking systems and industries. Let’s uncover everything there is to know about LIFO in the below sections.

Benefits Of Employing LIFO

Despite not being as popular as FIFO, the LIFO management method still possesses various advantages. Below is some evidence why companies prefer it over its famous pal.

- Optimizing warehouse space utilization: LIFO can lead to more efficient use of warehouse space, as it only requires a single lane for both loading and unloading items. Also, products are organized in highly accessible locations, thus reducing the need for extensive storage areas.

- Less traveling: Warehouse operators and forklift drivers will be happy about this benefit! With LIFO, they can travel less, thanks to the use of a common lane and the products being placed in easily accessible spots.

- Minimizing handling expenses: With the most recently added items typically located closer to the loading docks or positioned in a way that minimizes the need to move older stocks around, LIFO reduces the need for manual labor and equipment. As a result, handling expenses are also lowered.

- Simplifying product tracking: Tracking incoming and outgoing products is no longer a headache. As LIFO’s focus is on the most recently received units, the tracking process becomes much simpler, which eventually leads to fewer errors in order fulfillment and higher warehouse operational efficiency.

- Highly responsive to market trends: In industries characterized by rapidly changing consumer preferences or seasonal demand fluctuations, LIFO allows companies to adapt quickly to market trends. By prioritizing the newest stocks, businesses can respond promptly to demand shifts.

Drawbacks Of Employing LIFO

Now that you know some of LIFO’s amazing benefits, let’s talk about certain drawbacks that come with this storage rotation approach:

- Not representing the traditional product flow: The LIFO approach goes against the conventional product flow of most companies as they try to ship out the older items. This may pose certain challenges during its implementation.

- Leading to more expired or obsolete products: The newest items getting out first also means the oldest products being stuck inside the warehouse for a long time. Thus, there’s a high chance that these old stocks will expire or become outdated.

- Limited application: The unique approach of LIFO limits its application to a small group of product types only. You may consider this stock rotation method for items whose value won’t reduce over time.

Ideal Storage Systems For LIFO

Unlike its opposite cousin, LIFO utilizes only a single aisle for both the loading and retrieving procedures. Thus, this inventory management system requires some specific pallet racking types. Here are some names you can use in the LIFO system:

- Push-back pallet racking

- Drive-thru pallet racking

- Radio shuttle pallet racking

Suitable Application Of LIFO

If FIFO is ideal for perishable items, LIFO, with its opposing approach, works well with homogenous goods with no expiration date and no value loss over time. Some common examples include bricks, sand, stone, and coal.

It is strongly suggested for organizations whose capacity can uphold a substantial inventory level and do not require a specific product rotation schedule. Construction material is the perfect industry for the LIFO approach.

FIFO VS LIFO: Your Comprehensive Comparison

After grasping the basics of both approaches, it’s high time to put FIFO and LIFO to the ultimate showdown. The following part will compare these two stock rotation systems against a set of 10 different criteria. Alright, let’s begin!

#1: Inventory Flow

The first difference between the two stock management methods, FIFO and LIFO, lies in their opposite inventory flows. You can easily spot this difference by looking at their full names and definitions.

In the FIFO system, the most recently received products will be shipped out first, giving it the name “first in, first out”. On the other hand, the LIFO method ensures that the most recent added items will leave the warehouse last.

#2: Inventory Turnover

FIFO is suitable for companies with high inventory turnover, while using LIFO is more beneficial for businesses with low turnover rates. Implementing this correctly can help minimize the negative effects of their respective drawbacks.

For instance, employing the LIFO system in warehouses with low inventory turnover can prevent the risk of expired or obsolete products.

#3: Product Characteristics

FIFO and LIFO aren’t meant for the same type of product. If you take a closer look, the applicable products of each stock management system have vastly different traits, maybe even contradictory ones.

For example, storing apples, a type of fruit that, of course, has a limited shelf life, should be done with the FIFO system. However, if your product is coal, you should employ the LIFO approach, as coal is non-perishable.

#4: Inventory Accessibility

With the LIFO system, you can access the newly loaded product more easily, as it is often placed in locations near the shipping dock. This arrangement allows for more efficient retrieval procedures.

In contrast, locating that same newly loaded unit is much more challenging with the FIFO system. This is because FIFO focuses more on older inventory and reserves a more easily accessible spot for it.

#5: Order Fulfillment Speed

FIFO may lead to a slightly slower order fulfillment duration, especially if older stocks are stored in a way that requires additional handling or traveling to reach. Plus, the tougher tracking process also lengthens the time it takes to find the correct item for customers’ orders.

On the other hand, LIFO tends to do a better job and result in faster order completion. This is achieved as the newest products are often positioned closer to shipping areas for quicker and easier access.

#6: Warehouse Space Utilization

One of FIFO’s drawbacks is its requirement for a larger floor space or careful planning of such areas to ensure older units are not displaced by newer arrivals. This could lead to more complex warehouse layouts.

That’s when LIFO jumps to the rescue, allowing for a more straightforward warehouse arrangement. Unlike FIFO, you only need one common aisle for LIFO to do its magic. The most recently received products are also more accessible.

#7: Adaptability To Market Changes

Regarding the ability to adapt to market changes, LIFO is surely the winner! Thanks to its focus on newer items, LIFO allows for quicker responses to any trend shifts or market fluctuations.

Unfortunately, this is like “mission impossible” for the FIFO stock rotation approach. It takes more time and effort to track and locate the correct unit load for shipment with FIFO. Thus, it is definitely not the go-to choice in this rapidly changing world.

#8: Handling Costs

This is another category where LIFO has an edge. The employment of the LIFO system will potentially lead to lower handling expenses as the newest items are strategically placed for quicker retrieval.

FIFO, however, tends to incur slightly higher handling costs due to the need to move many units around to access the oldest inventory for shipment. This system also requires more manual labor and advanced equipment to make things work.

#9: Applicable Pallet Racks

Another key difference between FIFO and LIFO is their respective applicable pallet racks. In other words, each stock management style can only go with some specific pallet racking systems.

For example, drive-in pallet racks are ideal for the FIFO approach as they allow for goods to be loaded on one end and unloaed on the other end. On the other hand, with the use of one single lane for both procedures, drive-thru racks are perfect for the LIFO style.

#10: Applicable Industries

Similar to pallet racking systems, FIFO and LIFO are also applicable in certain industries. Selecting the wrong stock rotation approach for your field can lead to awful consequences.

FIFO is ideal for products with an expiration date, such as food or pharmaceuticals, while LIFO works best for items with no expiration date, like construction materials.

Showdown Recap Of FIFO VS LIFO

If you’re in a rush, feel free to take the shortcut with the following recap table. It displays everything about the FIFO vs LIFO comparison in a more concise way. Don’t forget to go over the details above again when you’re available.

| FIFO | LIFO | |

| #1: Inventory Flow | FIRST units in going out first | LAST units in going out first |

| #2: Inventory Turnover | Suitable for companies with HIGH turnover rates | Suitable for companies with LOW turnover rates |

| #3: Product Characteristics | Perishable, having an expiration date | Non-perishable, having no expiration date |

| #4: Inventory Accessibility | Lower | Higher |

| #5: Order Fulfillment Speed | Lower | Higher |

| #6: Warehouse Space Utilization | Lower | Higher |

| #7: Adaptability To Market Changes | Lower | Higher |

| #8: Handling Costs | Higher | Lower |

| #9: Applicable Pallet Racks | Selective racks, drive-in racks, pallet flow racks, satellite racks, live pallet racking, AS/RS | Push-back racks, drive-thru racks, satellite pallet racking |

| #10: Applicable Industries | Food, cosmetics, and pharmaceuticals | Construction materials |

Which Stock Management Should You Select: FIFO VS LIFO?

Now that you are familiar with both stock management systems, together with their similarities and differences, let’s get down to the main question of which one you should choose for your warehouse. Here are some angles to look at when answering that question:

- Understanding your product: To make the right selection between FIFO and LIFO, the most important aspect is to understand your product. Is it perishable or easily outdated? Does it lose value quickly over time? If yes, then go for FIFO. Otherwise, LIFO is your better choice.

- Understanding your market: After knowing your goods, let’s move on to understanding the market you’re doing business in. Are there many market demand shifts? Do new trends often emerge? If yes, then go for LIFO. But if the answer is no, FIFO will be more suitable.

- Understanding your warehouse: Taking a closer look at your warehouse is the next crucial step. What types of pallet racking are you currently using? Which do you prefer: a complex or minimal warehouse layout? Having the answers to those questions will help you pick your ideal stock rotation system.

Summary

This article has presented everything there is to know about FIFO vs LIFO, the two most widespread stock rotation systems out there. Not only sharing the basic understanding of each system, but the content herein also compares the two against a set of ten criteria.

Hopefully, the detailed comparison in this article has provided great insights to aid you in the selection process, as the right choice will lead to remarkable performances for your warehouse. Thanks for reading!