Warehouses always look good when they have appropriate racking systems in place. It is very important for them to boost productivity, and optimize space.

Opting for modern warehousing methods like efficient racking systems may offer ease. If you are interested in learning about the modern warehousing methods you can read this guide below.

The Importance of Modern Warehousing in Today’s Supply Chain

Modern warehousing techniques play a vital role in the supply chain and allow efficient movement and storage of products. The rise of e-commerce has shifted the focus of customers to have quick deliveries and the warehouse needs to meet the demands of increasing inventory.

Modern racking systems improve accessibility and the presence of the racking systems provides the ability to fulfill the order on time. It even helps to minimize the risk of errors during the process of packing and picking.

These days efficient warehouse racking systems are very important to meet the logistics requirements. Different techniques are present in the racking systems that ensure proper warehouse organization.

Apart from organization it even helps with accessibility of the products. The efficient techniques for modern warehouse design comprise of drive-in racking, pallet flow racking, and selective pallet racking. These racking systems can also be integrated into the warehouse management software and allow one to keep an eye on the stock levels.

Modern Warehouse Design: Optimizing Space with Efficient Racking Systems

Modern warehouse design boosts the optimization of racking systems with efficiency. When it comes to considering these modern warehouse designs, some of these aspects to consider are as follows:

Space Optimization with Advanced Racking Designs

The advanced designs of racking offer space optimization. Some of the commonly opened designs of racks that can be chosen for the efficiency of a warehouse are as follows:

- Pallet Racking: It is suitable for retrieving the stock easily and for high-density storage.

- Cantilever Racking: Cantilever racking is suitable for items that are bulky and long like lumber and pipes.

- Drive-In/Drive-Through Racking: This racking system requires forklifts to access the storage areas and they have a dense storage capability. These racking systems ensure to take less space and enhance the workflow and capacity of the racking.

The racking system’s efficiency is based on its adjustability and flexibility. The scalable racking systems ensure flexibility as the inventory fluctuates a lot. These racking solutions can easily be reconfigured and tend to accommodate the volume and sizes of the different products.

Technology Integration into Racking Systems

The smart sensors and IoT can also be integrated into these racking systems which helps with appropriate inventory management. The real-time data of the stock levels and movement is achieved. The smart sensors even can provide automated alerts for restocking which enhances overall efficiency.

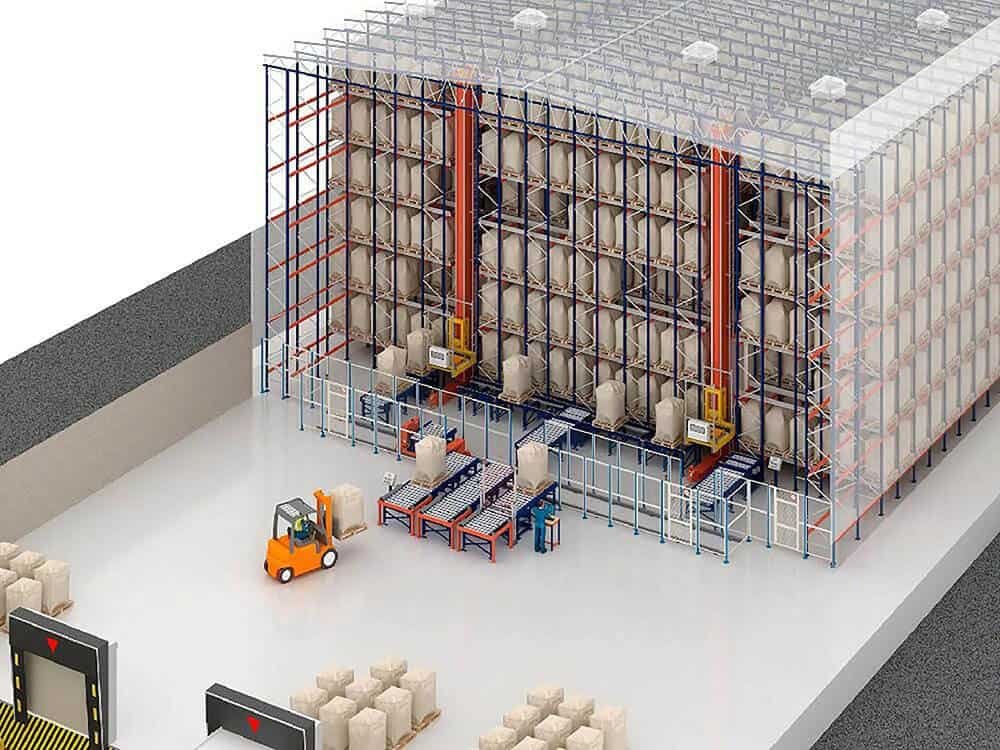

The Automated Storage and Retrieval systems use AI to retrieve and store goods and have very minimal human intervention. Such systems tend to reduce the cost of labor and even boost the speed of order fulfillment. Such systems are highly suitable for warehouses where a high volume of products are stored.

Sustainability in Modern Racking Solutions

Modern trends in warehousing take into consideration space optimization and efficiency and also keep sustainability as a prime concern. Durable and recyclable materials are chosen to manufacture these racking systems.

The main aim lies in minimizing the environmental impact and even the finishes and coating used on the racking system are not harmful to the environment.

Warehouses equipped with optimization of the racking system also help in reducing the consumption of energy. These systems when utilized appropriately help to reduce the use of space and tend to lower the use of cooling, lighting, and heating. Hence, it offers energy-saving practices.

Modern Warehousing Techniques for Improved Efficiency

There are different ways you can improve the efficiency of your warehouse, and some of these modern warehousing techniques are discussed in this section.

High-Density Storage Racking Systems

The high-density storage rack systems help to maximize the storage capacity when you have limited space. This comprises using double deep pallet racks and push-back racks.

Double deep pallet racks allow for incorporating two pallets one after the other and the need to have additional aisles eliminated. Whereas, the push-back racks help include the pallets from the front, and these racks are pushed back on the inclined rails. These racking systems expand the storage capacity of a warehouse without expanding the footprint of the warehouse.

Apart from this, the storage capacity can be further enhanced through vertical storage solutions. It comprises mezzanine racking systems that make the most of the height of the warehouse and add more storage levels without taking too much of the floor space.

Lean Warehousing Techniques with Optimized Racking

Learn warehousing focuses on maximizing the warehouse’s efficiency by reducing waste. The lean warehousing method works by eliminating the need for excessive handling and streamlining the storage capacity. This concept works by reducing the travel time for picking up the products and also minimizing the stock held.

Moreover, JIT stands for Just-In-Time inventory methods which offer flexible racking solutions which can adjust the storage based on the demand. When adjustable racking systems are incorporated, the warehouses are able to accommodate the fluctuating demands of inventory. It helps to avoid stock-piling and also reduces waste.

Data-Driven Racking Layouts

The combination of warehouse management systems and data analytics has transformed the way racking systems work and offers insight into the flow, pattern, and demand of inventory.

The warehouse management systems and data analytics can integrate with the racking setups so that the efficiency of racking solutions can be determined to help meet the high storage demands. It can also reduce labor costs by managing the warehouse efficiently.

These systems even help with inventory forecasting by predicting future inventory needs based on past patterns. Hence, the warehouses can adjust the racking layouts to accommodate the future stock demand.

Modern Trends in Warehousing and Racking

The modern trends in racking and warehousing have also helped businesses streamline their inventory in an efficient way. Some of these ways are discussed here.

Automation in Racking Systems

The modern warehouse incorporates automated racking solutions. This consists of having smart racks and robotics that pick the products. It helps to improve the efficiency of the warehouse and the time spent in storing and retrieving inventory is reduced.

The smart racks on the other hand have sensors that keep a check on the stock levels and provide alerts when the stock levels are low. Such systems improve the efficiency of the warehouse and reduce manual intervention.

E-Commerce and Customizable Racking Systems

The growth of e-commerce has created new demands on warehousing and they need an effective solution that helps meet the order fulfillment in the quickest possible way. The customizable racking systems have the ability to handle large as well as small goods. They are adjustable and can be scaled when businesses need to adjust inventory levels in the future. These systems meet the competitive environment that prevails in e-commerce.

Sustainability and Green Racking Solutions

The modern warehouse is also inclined towards adopting sustainable racking solutions that are eco-friendly. These systems are made using materials that can be recycled and have an eco-friendly coating.

Modern racking systems are even designed to make the most of energy efficiency. They help in space optimization and even reduce the lighting, heating, and cooling requirements for a warehouse.

The Role of Modern Warehousing in Logistics: Racking Solutions for Optimized Flow

Modern warehousing in logistics leads to designs such as racking systems that boost material handling and keep the flow of products continuous and efficient.

Seamless Integration of Racking and Material Handling

Modern racking systems have advanced techniques incorporated to handle the inventory. These methods are composed of conveyor belts and forklifts which efficiently mow the inventory. These systems reduce the time for loading and unloading the inventory and the overall warehouse efficiency improves.

Inventory Management with Modern Racking Systems

Racking systems play a major role in enhancing inventory management as modern warehousing allows for organized storage followed by quick product access. These optimized racking systems enhance the overall inventory management making the lead times shorter and accessibility easy.

Cold Storage and Specialized Racking

Specialized racking systems are such systems that are designed to cater to special purposes, like cold storage. These systems have efficient temperature systems and can safely store items that are required to be kept under a certain temperature. Moreover, the innovations in these racking systems comprise materials that are corrosion-resistant and can meet the specific requirements of storage.

Challenges and Opportunities in Modern Warehousing Racking

Modern warehousing which brings ease and efficiency also has some challenges. This section highlights the challenges that come with modern warehousing and what opportunities for growth it may offer in the future.

Key Challenges in Racking System Design

Modern warehouse racking systems may be challenging because the space limitations, changes in inventory demands, and the requirement for having high-density storage prevails very commonly.

The warehouse has multiple ranges of products which have different sizes and the stock fluctuates. Hence, maintaining efficiency can become a task, and incorporating automated technologies is also difficult.

Opportunities for Growth with Advanced Racking Solutions

However, on the other hand, the modern warehouse racking systems also offer smart and automated racks which enhances the warehouse efficiency by maximizing the storage. These are very sustainable and use the height of the warehouse very smartly. Hence, the cost in the long run may be reduced, and due to the environment’s friendliness, they can be ideal for future growth.

Conclusion

Modern warehousing requires incorporating modern racking systems smartly and planning the warehouse in a way that optimizes space and efficiency. When it comes to choosing the best racking systems, the name Lracking is a leading one. We offer the finest custom racking systems which have innovative features to cater to your warehouse. So, contact us today and share your warehouse specifications.