Pallet Rack Accessories

See all of Lracking's Pallet Rack Accessories

Pallet Racking Upright

Pallet racking upright is a vertical component of a pallet rack system that supports and holds palletized goods. The uprights are typically made of strong steel beams and are positioned vertically to provide stability and durability to the entire pallet rack structure. They are the main vertical support system between each level of the rack and provide the framework for the beams that hold the pallets. The uprights usually have holes or slots to allow for the attachment of horizontal load-bearing beams. They also have plates or other mechanisms at the bottom to anchor the upright to the floor and ensure stability. Pallet racking uprights are essential to creating a safe and efficient storage solution for warehouses, distribution centers, and other businesses that require organized and efficient storage of large quantities of goods.

Pallet Racking Beam

Pallet racking beam is a horizontal component of a pallet racking system that provides support for pallets and their loads. The beam is an essential element of a pallet racking system and supports pallets at their ends. It is usually made of heavy-duty steel and comes in many different lengths and weight capacities to accommodate a variety of pallet sizes and weights. The beam is designed to fit into uprights or frames that are anchored to the floor, creating a sturdy and safe storage system for pallets. Pallet racking beams can be adjusted to different levels, allowing for maximum use of vertical space. They also feature safety measures such as locking pins to ensure that they stay securely in place and prevent accidents. Pallet racking beams are commonly used in warehouses, distribution centers, and factories to store large quantities of materials.

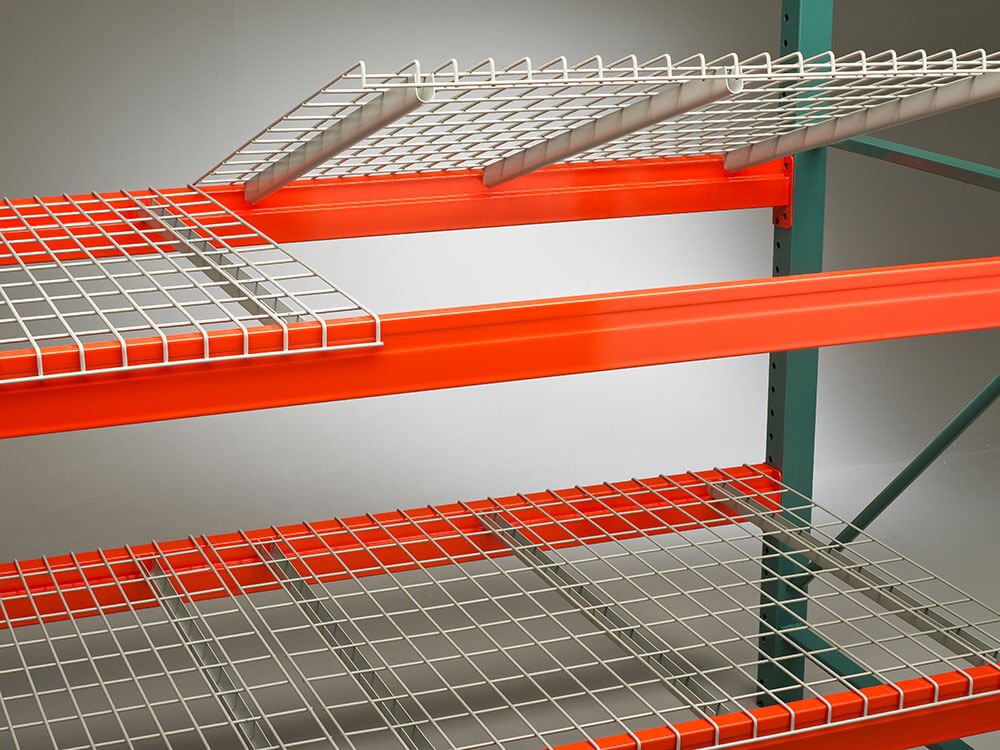

Pallet Racking Decking

Pallet racking decking refers to the material used to create a flat surface on the beams of pallet racking systems. Pallet racking systems are used in warehouses and other storage facilities to store goods and materials off the ground and in an organized manner. The decking provides a stable and safe surface for the pallets to be placed on. There are different types of pallet racking decking, including wire decking, steel decking, and solid wood decking. Wire decking is the most common type and is made of wire mesh that is welded to the beams, providing a stable and durable surface. Steel decking is made of solid steel and provides a heavy-duty option for larger or heavier items. Solid wood decking is a cost-effective option and is often used for smaller or lighter items. Overall, pallet racking decking is an essential component of pallet racking systems, ensuring safe and efficient storage of goods and materials.

Pallet Support Bars

Pallet support bars are horizontal bars that are placed underneath the pallets within a racking system to provide additional support to the pallets and prevent them from sagging or collapsing. These bars are usually made of steel and come in different lengths and thicknesses to fit different sizes of pallets and to support different weight capacities. Pallet support bars can be set up in a variety of ways, but most commonly they are installed parallel to the direction of the pallets. Some systems may require the use of additional hardware, such as clips or hooks, to secure the bars in place. Pallet support bars are an essential component of pallet racking systems and help to improve safety, efficiency, and productivity in warehouses and distribution centers.

Pallet Racking Boards

Pallet racking boards are specialized boards that are used in pallet racking systems to provide a stable surface for storing goods. They fit into the horizontal beams of the racking and create a flat shelf-like structure on which pallets, boxes, or other items can be stored. The boards are made from different materials, including wood, steel, wire mesh, or plastic, depending on the application and the weight of the goods being stored. They come in different sizes to accommodate different pallet sizes and can be customized to fit specific storage needs. The use of pallet racking boards helps to increase the efficiency of storage spaces by maximizing the vertical space available and making it easier to organize and access inventory.

Pallet Rack Guards

Pallet rack guards protect workers and equipment from rack damage and collapse. They come in various styles, installed on corners and ends to prevent machinery from damaging the rack. Using pallet rack guards ensures a safer work environment, minimizing injuries and equipment damage. Choosing guards requires considerations such as rack type, inventory weight, and forklift traffic frequency. High-quality materials, proper installation, and regular maintenance contribute to guard longevity and effectiveness.

Upright Protectors

Pallet racking upright protectors are safety devices that are used to protect uprights from accidental damage or impacts in high traffic areas. These protectors are designed to absorb the force of an impact and prevent the racking from collapsing or tipping over. Made from heavy-duty materials, such as steel or plastic, these protectors attach to the uprights with bolts, sleeves or clamps, forming a barrier around them. They are available in various sizes and are suitable for different types of pallet racking systems. The use of pallet racking upright protectors is considered essential for maintaining a safe and stable warehouse environment, preventing costly damage to inventory, and reducing the risk of workplace accidents and injuries.

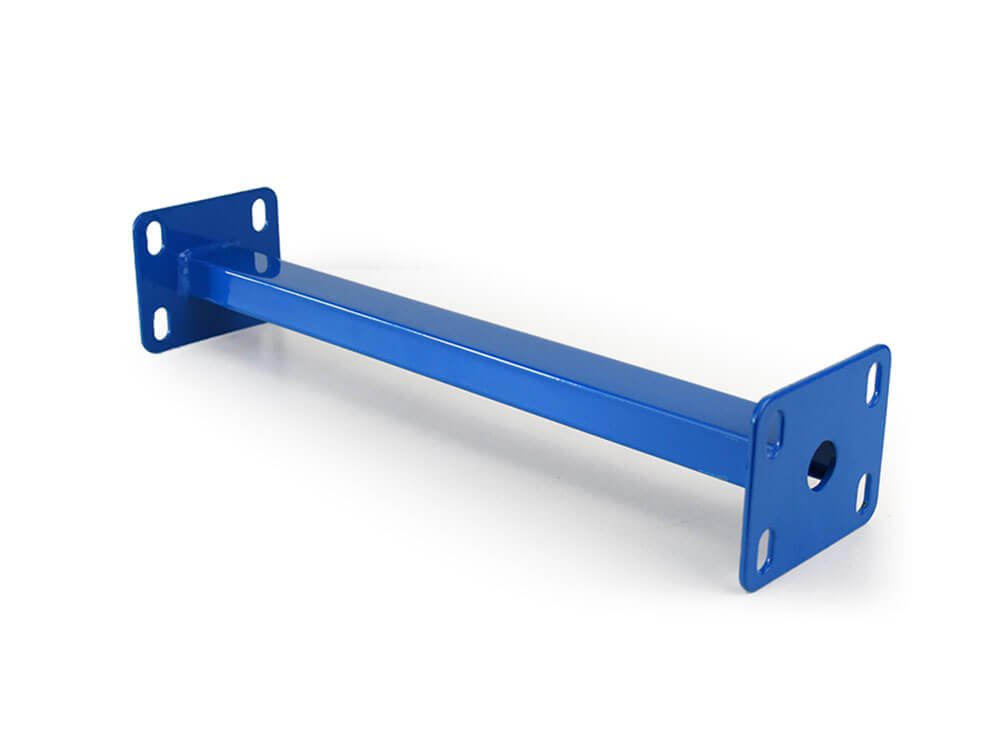

Row Spacer

Pallet racking row spacers are key accessories for warehouse racks, helping ensure proper spacing and stability. Available in various sizes and styles, the types of spacers include offset and flush. Offset provides spacing to make forklift maneuverability easier, while flush connects close racking rows preventing damage in transit. The benefits of using pallet racking row spacers are many, including increasing safety and stability in warehouse setups while creating clean and organized storage for workers.

Pallet Shuttles

Pallet shuttles are used for shuttle racking, an advanced warehouse storage racking system. The system involves an automated shuttle cart that moves along the storage lanes and arranges the pallets in the designated slots. Unlike traditional storage systems, the pallet shuttles eliminate the need for human intervention to operate forklifts, thus improving the warehouse’s space utilization and reducing the risk of accidents. Pallet shuttles also offer high-speed pallet loading and unloading capabilities, making them ideal for large-scale warehouse operations with high inventory turnover rates. The system is highly customizable and can be tailored to fit different warehouse layouts, making it an ideal option for modern warehouses looking to maximize their storage capacity and streamline their operations.

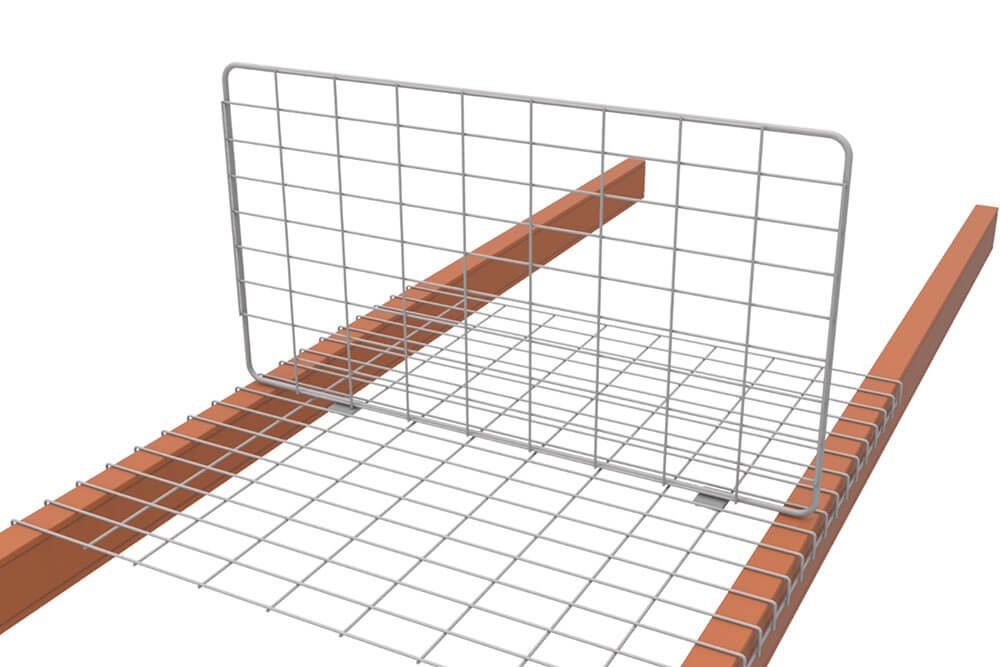

Pallet Rack Dividers

Pallet rack dividers are an accessory that can be attached to the beams of a pallet racking system to separate and organize stored inventory. These dividers can be composed of a variety of materials, including wire mesh, steel, or plastic. They come in various sizes and designs to fit different pallet sizes and storage requirements. Using pallet rack dividers improves warehouse organization by creating designated areas for specific products and preventing them from shifting or mixing with other goods. They also make it easier and more efficient to locate items, as well as reduce the risk of damage to goods. Pallet rack dividers are a cost-effective solution to optimize warehouse storage space and enhance productivity.

Pallet Racking Netting

Pallet racking netting is a type of safety netting system that is used in warehouses and other industrial facilities to prevent accidents caused by falling objects. It is installed between the pallet racks to provide an additional layer of protection for workers and equipment. The netting is made from strong and durable materials that are designed to withstand the wear and tear of daily use. It is available in various sizes and configurations to fit different pallet racking systems and can be customized to suit specific needs. Pallet racking netting is an effective way to enhance workplace safety and prevent injuries and damage to products and equipment.

Pallet Rack Safety Clips

Pallet rack safety clips are small accessories that are attached to the beams of a pallet rack to ensure that the beams stay securely in place. Pallet racks are essential storage systems in warehouses and other industrial settings, allowing goods to be stacked on top of one another for efficient use of space. However, these racks have the potential to be unstable, especially when heavy loads are being stored. This is where pallet racking safety clips come in. These clips are designed to hold the beams in place and keep them from shifting or dislodging, preventing accidents and ensuring the safety of workers and stored materials. Pallet racking safety clips are easy to install and can provide significant peace of mind to warehouse operators and managers.