Pallet rack decking is an integral component for increasing storage space, improving warehouse safety, and optimizing stock management. It converts your pallet racking system into a flexible inventory solution that can accommodate a wide range of items while maintaining stability and protection.

With so many decking options to choose from, it can be difficult to make an informed decision. From wire mesh to steel decking, each style has distinct benefits and addresses certain storage requirements.

This detailed guide will look at the many varieties of pallet rack decking available, their important pros and cons, as well as factors to consider when making your choice. Whether you’re dealing with heavy industrial loads or delicate products, this article will help you make an educated selection and maximize your inventory system.

Why Should You Care About Pallet Rack Decking?

Resting on the pallet racking system’s support beams is a horizontal surface called “pallet rack decking”. Consider it an additional shelf that provides a continuous platform inside each storage bay.

The main goal of pallet rack decking is to create a sturdy and secure platform for holding palletized products. While pallet racks offer support, decking ensures that these structures are equally distributed and do not fall through the spaces between beams, which possibly injures staff or damages the products below.

In addition, this racking element increases the adaptability of your storage solution by enabling you to store a greater variety of items. Smaller, loose objects, cartons, and even non-palletized commodities can be securely kept on decking, thereby making the most use of your warehouse space.

The benefits outlined above explain why many people employ pallet rack decking in their warehouses. Yet, with so many different options available as well as concerns like load capacity, fire safety, and budget, selecting the proper decking for your specific demands can be challenging. Let’s first explore the top decking options in the following section.

Discovering The Top 10 Pallet Rack Decking Options

This section will uncover the top 10 pallet rack decking options that deserve your consideration. In each decking type, you’ll explore what it is, how it can benefit your inventory facility, and what shortcoming you should be aware of before utilizing it.

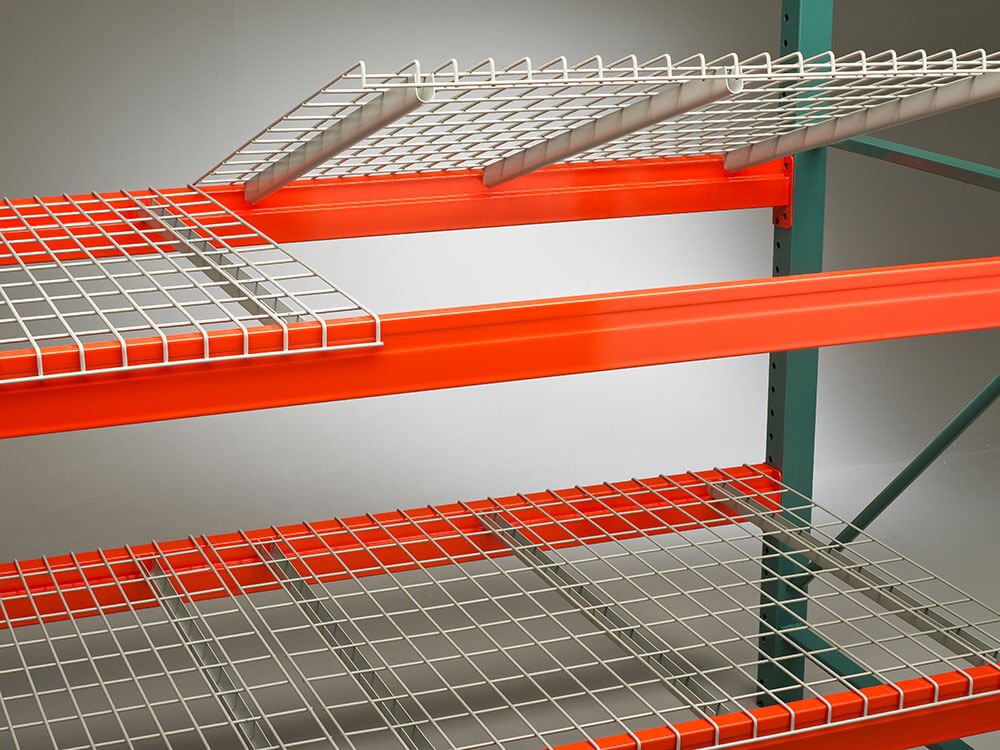

#1: Wire Mesh Decking

Striking a beautiful balance between durability, affordability, and safety, wire mesh decking is the most common option for pallet racking systems. It’s typically made of industrial-grade steel wires that have been welded into a grid pattern and provides a flexible solution for a wide variety of storage requirements.

One primary benefit of this decking type is its excellent fire resistance. Its open design enables sprinklers to properly reach all levels of the racking system, thus reducing fire risks. Furthermore, the mesh provides enough ventilation and light penetration, resulting in a safer, cleaner, and more pleasant working environment.

That feature makes it suitable for warehouses that handle food and medicines. Also, thanks to its top-notch versatility, wire mesh decking can store numerous objects, including pallets, cartons, drums, and other irregularly shaped items.

PROs:

- Offering excellent fire safety.

- Preventing small products from falling through.

- Facilitating great ventilation and light penetration.

CON:

- Not well-suited for very heavy loads.

#2: Plywood Decking

Believe it or not, plywood decking can be a highly cost-effective solution for your pallet racks. In addition to its affordability, this decking option is capable of storing lighter loads of varied forms and sizes. Its versatility enables open storage layouts with easy access to goods.

The smooth surface of plywood decking protects delicate items from scratches or damage during storage and retrieval. Moreover, it’s quite straightforward to install and replace, making it an ideal alternative for companies looking for a fast and easy decking solution.

Nevertheless, plywood decking does have certain limitations. It’s prone to moisture damage and warping, rendering it unsuitable for humid conditions or outdoor storage. The decking option is also not fire-resistant and can be damaged by sprinkler systems, creating possible safety hazards in the event of a fire.

PROs:

- Highly cost-effective.

- Simple to install and replace.

- Available in different thicknesses.

CONs:

- Vulnerable to moisture damage and warping.

- Not fire-resistant.

#3: Solid Steel Decking

Have you ever wondered how warehouses manage gigantic, oddly shaped goods that seem to defy gravity? Well, the answer lies in a seemingly simple yet incredibly strong solution: solid steel decking.

Solid steel decking converts your pallet rack into a storage fortress capable of carrying even the largest loads. Its smooth surface is ideal for bulk storage, bagged products, and even those pesky small objects that may slide between the cracks of other pallet rack decking options.

But this powerhouse is more than just raw strength. Besides being resistant to abrasion and steel, solid steel decking serves as a safety net, collecting leaks and spills from boxes or pallets. This helps avoid messy mishaps and potential risks.

This decking solution is normally constructed from 14-gauge steel sheets reinforced with 12-gauge steel channels on the bottom for maximum strength. This combination supports up to 3,000 pounds per deck piece, and the 1.5-inch waterfall edges on the front and back ensure a secure fit on standard 1.625-inch step beams.

PROs:

- Offering superior durability and a long lifespan.

- Having a high load capacity.

- Highly resistant to abrasion and impact.

CON:

- Potentially obstructing sprinkler systems.

- It is usually more expensive.

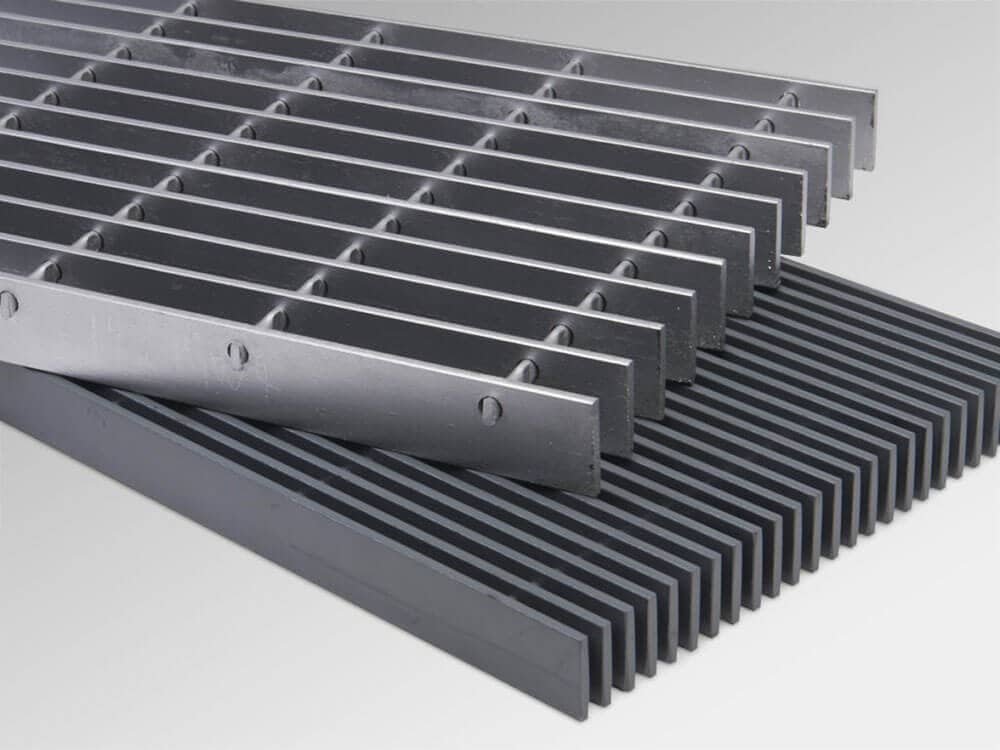

#4: Bar Grating Decking

Did you know that bar grating decking is actually a form of steel grating made exclusively for pallet racking systems? Unlike wire mesh, bar grating employs larger, solid metal strips instead of wires, giving it a high load-bearing capability.

This distinctive design makes bar grating decking suitable for warehouses that store heavy objects having irregular shapes with concentrated weight distribution. Consider those big industrial pieces of equipment with small feet; bar grating can easily manage them! A single piece can sustain 4,000 pounds or more, depending on the steel thickness used.

However, strength is not its sole asset. Because of its open design, bar grating performs well in terms of fire and ventilation. This enables sprinkler systems to work properly and guarantees enough airflow, leading to a safer warehouse environment.

It’s worth noting that under heavy loads, the spaced metal bars of this decking option might vibrate and make noise. This noise can be bothersome to workers and even violate noise restrictions in certain regions. Thus, warehouses with noise concerns should look into other decking choices.

PROs:

- Supporting high load capacity.

- Providing excellent ventilation and drainage.

- Allowing for light penetration.

- Highly corrosion-resistant.

CON:

- Causing noises when placing heavy objects on the decking.

#5: Perforated Decking

Perforated decking is crafted from robust 14-gauge steel (like that of solid steel decking), but features a distinctive pattern with 1-inch holes strategically spaced over the surface. These perforations have two functions: (1) boosting fire safety by enabling sprinkler water to penetrate, and (2) providing ventilation for stored items.

While resembling solid steel decking in strength, the perforations lighten the load, making it simpler to handle and install. The 12-gauge steel reinforcing channels beneath guarantee that it can withstand up to 3,000 pounds per piece, thereby widening its application.

The smooth powder-coated surface of perforated decking prevents stored products from harm, and the waterfall edges provide a tight fit on standard pallet rack beams. Yet, although the perforations are useful for fire safety and ventilation, they may not be suitable for housing textiles and other delicate items that can snag on the holes.

PROs:

- Enabling light penetration.

- Super easy to clean.

- Stopping small-sized objects from falling through.

CON:

- Not as robust as solid steel decking.

#6: Chipboard Decking

Although both chipboard and plywood decking are derived from wood, there’s a significant difference in their composition. While plywood comprises thin layers of wood veneer cemented together, chipboard is formed by compressing and bonding wood chips and resin under heat.

This distinction offers chipboard decking a smoother surface, allowing it to store materials like carpets that need a clean finish. It comes in a variety of densities, including high-density options capable of holding up to 2,200 pounds.

When compared with other pallet rack decking types, chipboard decking is the most cost-effective option. However, it may not be the best option for large loads or deep bays. Not to mention, if not appropriately maintained, it can sag or bend with time, jeopardizing the stability of stored items.

PROs:

- Acting as the most economical option.

- Very lightweight.

- Simple to cut and assemble.

CON:

- Prone to moisture damage.

#7: Medium-Density Fiberboard (MDF) Decking

Despite having comparable costs and smooth surfaces, medium-density fiberboard (MDF) decking has a clear edge over its chipboard counterpart in terms of density and moisture resistance. As the name implies, MDF decking is denser than chipboard decking, thereby providing greater durability and stability under heavier weights.

Also, the composition of fine wood fibers and resin makes MDF more resistant to warping and drooping than chipboard. This increased resilience leads to a longer lifespan and higher reliability in various warehousing settings.

It’s not only useful but also visually appealing. MDF’s flat surface really accepts paints, stains, and other treatments, allowing for modifications to complement your warehouse’s aesthetics. However, due to its vulnerability to moisture damage, MDF is not appropriate for outdoor usage or high-humidity environments.

PROs:

- Offering consistent density, ensuring even support across the entire decking surface.

- Matching warehouse aesthetics easily with paint, stains, and other finishes.

- Highly resistant to insects and rot.

CONs:

- Not moisture-resistant.

- Not well-suited for outdoor applications.

#8: Plastic Composite Decking

Many warehouses are starting to employ plastic composite decking because of its unique combination of durability and resistance. Unlike wood, it’s impervious to dampness, rot, and insect damage, making it a long-lasting option for both indoor and outdoor inventory.

In addition to that resistance, which translates into lower maintenance costs and a longer lifespan than standard wood decking, plastic composite decking is also capable of enduring high loads and severe temperatures. Its non-porous surface resists stains, chemicals, and impact, thus offering a clean and safe working environment.

Although somewhat more costly than wood-based decking options, plastic composite decking provides better long-term value. However, in wet conditions, please be aware that this decking surface becomes slippery, posing greater risks to warehouse employees.

PROs:

- Durable and long-lasting.

- Impervious to moisture and outdoor weather conditions.

- Demanding low maintenance.

CON:

- Becoming slippery when wet.

#9: Flow-Through Decking

Flow-through decking is the foundation of gravity-flow pallet racking systems. It has rollers or wheels that enable pallets to easily slide from the loading end to the picking face while following a slight inclination. This innovative design allows for a FIFO inventory rotation, prioritizing older stock and lowering the danger of product expiration.

This decking option not only optimizes stock management but also increases warehouse efficiency. Using gravity to move pallets lowers the requirement for forklift intervention in the racking aisles. This reduces traffic congestion while simultaneously lowering labor expenses and increasing overall productivity.

Although flow-through decking is initially more expensive, the long-term advantages outweigh the cost. It enhances inventory turnover, reduces product damage, and simplifies warehouse operations, resulting in cost savings and a more efficient supply chain.

PROs:

- Optimizing stock rotation by enabling the FIFO approach.

- Reducing forklift traffic, thereby improving warehouse safety.

- Enhancing storage density compared to conventional racking systems.

CON:

- Requiring relatively higher costs than other decking types.

#10: Cardboard Decking

Think cardboard is just for boxes? Think again! While sometimes ignored, cardboard decking can be an effective solution, particularly for those on a tight budget. But how does it do against wood-based alternatives like plywood, chipboard, and MDF?

Well, while not as robust as those counterparts, cardboard decking is more affordable and environmentally friendly. Made from recycled materials, it’s a sustainable option for organizations looking to reduce their environmental impact.

Its lightweight design also makes it very simple to install and handle, thus saving time and effort during setup. However, it’s important to note that cardboard decking is best suited for lightweight applications only. It’s not intended for heavy loads or continuous usage.

PROs:

- Very eco-friendly.

- Extremely lightweight, thus facilitating easy installation.

- Cost-effective for temporary needs.

CON:

- Not durable, making it suitable only for very light loads.

How To Choose Your Ideal Pallet Rack Decking

Now that you know all the popular pallet rack decking out there, it’s high time to learn how to pick the ideal option for your inventory facility. The process is straightforward, as you only need to consider the four following factors:

Assessing Load Capacity

Neglecting this critical factor is a recipe for disaster. Exceeding weight limitations can jeopardize rack stability, resulting in overloading and catastrophic collapses. To avoid such accidents, carefully assess the weight of your typical pallets and stored products when selecting the rack decking.

Once you have that figure, select a decking option that can comfortably support your highest loads while providing a built-in safety margin. But if you’re struggling to verify this factor, feel free to consult with a racking professional to identify the proper load capacity for your specific demands.

Using Certified Pallet Rack Decking

Uncertified pallet rack decking with substandard materials and workmanship can cause structural failures, placing your personnel and products in danger. Thus, to reduce these risks, only opt for certified decking that adheres to industry norms and regulations, such as those with Storage Equipment Manufacturers Association (SEMA) clearances.

Certified decking guarantees that materials and manufacturing processes meet high quality control measures. This ensures not only your racking system’s structural integrity but also its load-bearing capability, thereby facilitating a safe and compliant storage environment.

Ensuring Proper Fire Safety

Fire is the number one enemy of warehouses, presenting a serious threat to both goods and human safety. Therefore, during your selection of pallet rack decking, fire safety comes first. Choose materials and designs that allow for proper ventilation and sprinkler penetration.

Wire mesh and bar grating decking are ideal alternatives since their open layout enables sprinkler water to reach all levels and allows smoke to escape. If you want to use wood-based decking, pick materials that have been treated with fire-retardant chemicals and are designated as Class 0 or Class 1 to reduce flame spreading.

Determining Required Durability

How long do you expect your pallet rack decking to last? To answer this question, you need to determine your required durability. This factor is essential, particularly in busy warehouse settings. The sort of items you house, the frequency with which you access them, and even your cleaning practices all influence how long your deck lasts.

Heavy loads and regular forklift usage need more durable materials, such as solid steel or bar grating. On the other hand, smaller products are fine with the use of plywood or even cardboard decking for short-term storage. Briefly speaking, consider the wear and tear on your decking to ensure a long-lasting investment.

Pallet Rack Decking: A Complete Summary Table

This part is a one-stop location for all information about the top 10 pallet rack deckings presented above. Everything is packed into the following summary table, providing you with a quick and convenient way to brush up on knowledge whenever you’re available.

| Pallet Rack Decking Type | Load Capacity | Fire Safety/ Ventilation | Cost |

|---|---|---|---|

| Wire Mesh Decking | Medium | Excellent | Moderate |

| Plywood Decking | Light | Limited | Moderate |

| Solid Steel Decking | High | Limited | Expensive |

| Bar Grating Decking | High | Excellent | Expensive |

| Perforated Decking | Medium | Excellent | Moderate |

| Chipboard Decking | Light | Limited | Most affordable |

| MDF Decking | Light | Limited | Most affordable |

| Plastic Composite Decking | Medium | Limited | Moderate |

| Flow-Through Decking | Varies* | Varies* | Varies* |

| Cardboard Decking | Light | Limited | Most affordable |

* Flow-through decking varies contingent upon the layout and materials utilized.

Wire Mesh VS Plywood VS Steel: Which Should You Select?

Among the top 10 pallet rack decking options introduced above, wire mesh, plywood, and solid steel deckings are the most popular ones. The question is: how do you know when to use which decking type for your warehouse? Here’s a brief explanation just for you:

- Wire mesh decking: Thanks to its open design that allows for sprinkler water to flow freely and smoke to disperse, this option is a good choice for warehouses with rigorous fire rules or those that store hazardous products.

- Plywood decking: This cost-effective option is perfect for inventory facilities looking to keep lighter loads and objects of diverse shapes and sizes. However, beware that it’s flammable and not suitable for places with high fire risks.

- Solid steel decking: If you need an option for heavy-duty applications and facilities that store large, irregularly shaped objects, then solid steel decking is the go-to solution. Despite its incredible load-bearing capability, this option has restricted ventilation and is quite costly.

Conclusion

Bravo! You’ve now delved into the complexities of pallet rack decking, obtaining useful insights into the numerous varieties, their advantages, and critical factors for choosing the best solution for your warehouse.

Remember that selecting the correct decking is more than just about increasing storage space or improving aesthetics; it’s an important choice that affects warehouse safety, operational efficiency, and long-term cost savings.

Whether you choose the fire-resistant features of wire mesh, the low cost of plywood, or the impressive strength of solid steel, emphasize quality and industry compliance. Your warehouse’s performance is dependent on a well-designed storage system, and pallet rack decking plays an important role in attaining that objective. Thanks for reading!