Finding the appropriate pallet rack sizes for your inventory facility may save you a significant amount of money while also enhancing worker safety and boosting productivity. Knowing the right size and load capacity can also simplify the process of acquiring properly sized pallet racks, given the variety of options available.

Remember that your warehouse operations will only be successful if you can deliver orders efficiently. If your stored items are not well organized, production may be substantially lower than desired, leading to lower productivity and revenues.

While there are several actions you can take to boost warehouse efficiency, the most crucial one is having the correct pallet racking sizes. Though the job may seem difficult at first, you can easily get it done in just five easy steps. In this post, you’ll learn exactly what that process is and how to choose the ideal pallet rack dimensions.

Exploring Standard Pallet Rack Sizes

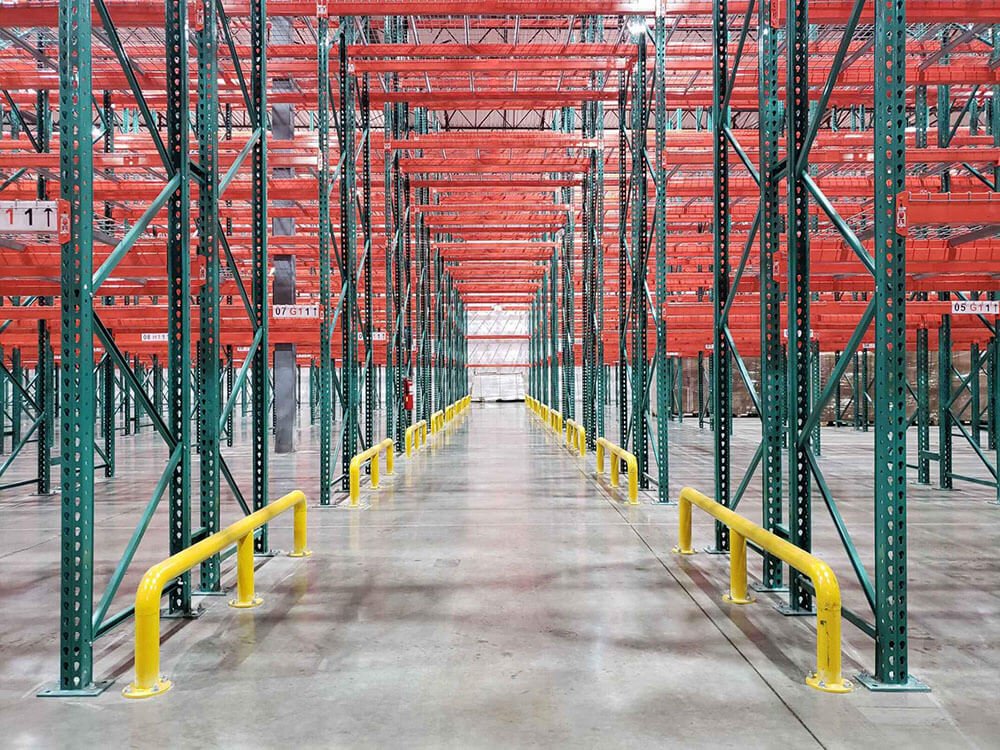

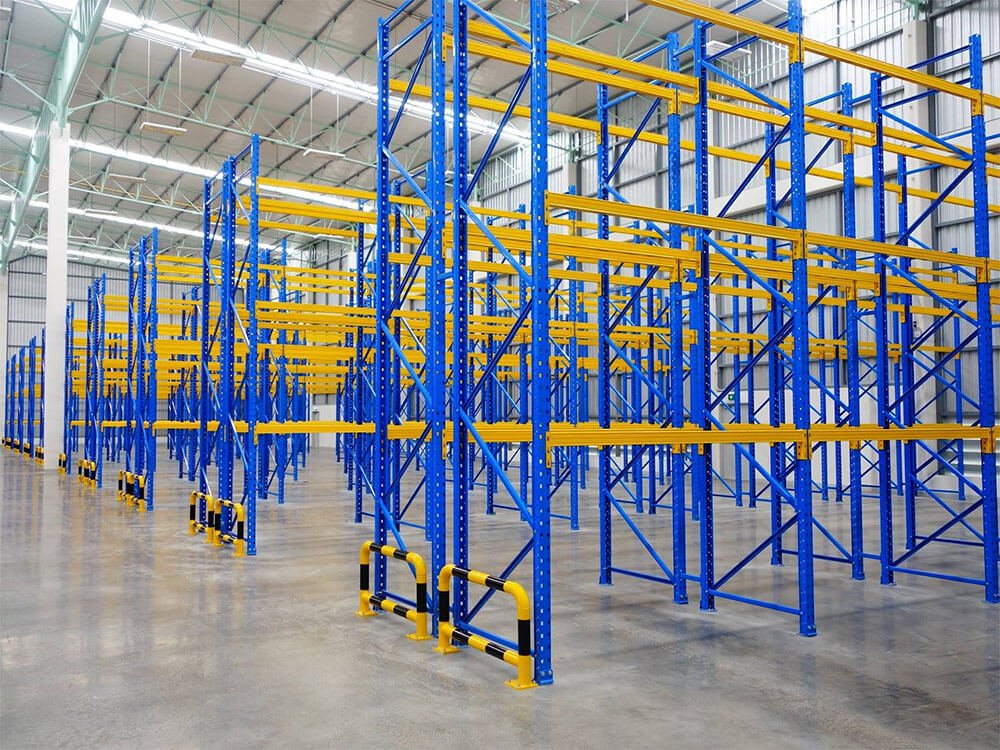

Pallet racking systems are indispensable for all warehouses and distribution centers. They are meant to provide you with room to store and organize your items until they are ready for delivery. These steel constructions are composed of upright frames, posts, cross braces, and horizontal beams.

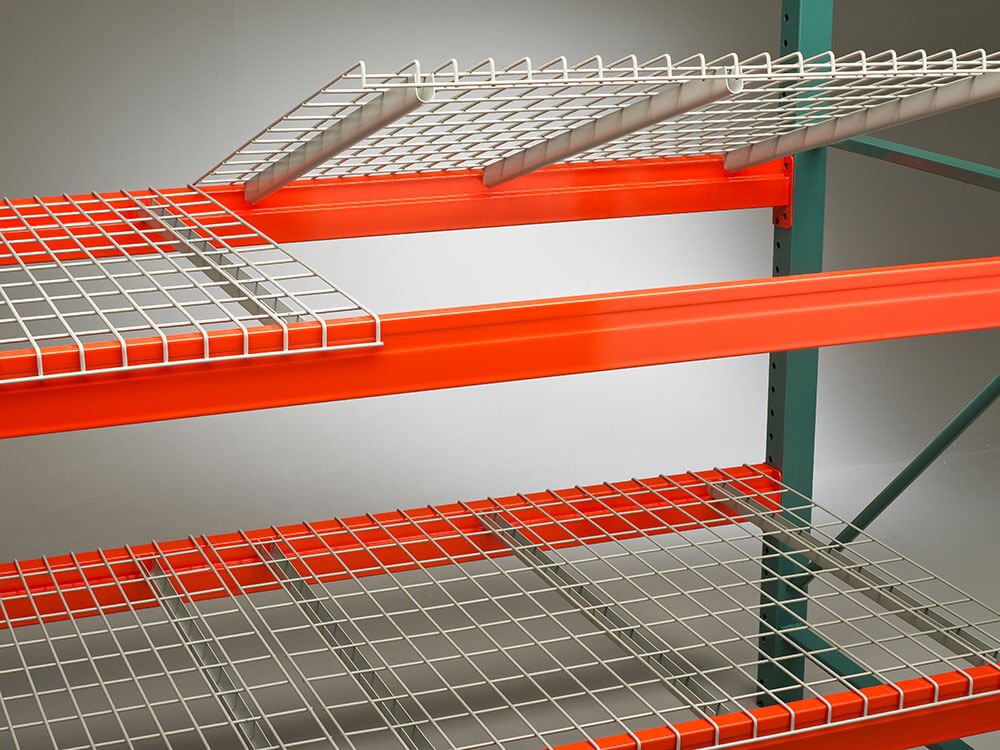

The pallet weight is supported by beams positioned between each upright. Higher uprights are equivalent to beams that are more widely spread apart. Frames and beams are often joined in two ways: by attaching each component to the uprights or by utilizing an interlocking mechanism to establish a slotted connection for each element.

Before deciding on a pallet racking system, you need to establish the size of your pallets. The pallet rack standards include the size of 40-inch wide by 48-inch deep, although these dimensions may vary depending on your products.

After selecting your pallet rack dimensions, you may determine the system’s depth as well as the pallet rack upright sizes. These figures will allow you to know what pallet rack beam sizes to purchase. The typical rack height is 7,620mm (25 feet), but you should always consider the height at which your forklift can move to find this number.

Choosing The Right Pallet Rack Dimensions With 5 Simple Steps

When attempting to determine the correct pallet rack sizes, you need to consider a wide array of aspects. Having an unclear process in mind might take you a ton of time, which can harm your productivity and efficiency. In this part, let’s unveil a simple 5-step procedure to pick your ideal pallet rack dimensions.

Step #1: Figuring Out Your Inventory Demands

Determining your storage requirements is the first task you should carry out in this 5-step process. Besides the standard pallet rack sizes of 48-inch deep and 40-inch wide, pallets come in a variety of other sizes.

So, in order to figure out which pallet racks to purchase, you should know the weights of your average and largest pallets. If you erroneously put too much weight on the racks, the whole system will become a safety risk.

When evaluating the necessary inventory capacity, let’s consider numerous aspects, including the pallet load sizes, warehouse space, and the amount of pallet depths, beam levels, pallets per beam level, and racking levels.

Use these values to assess your warehouse’s storage capacity and determine how many pallets you can employ.

Step #2: Computing Pallets’ Weight And Size

Once you’ve figured out your inventory demands, it’s easy to determine the suitable size and weight of your pallets. To be specific, let’s write down the following two key figures: (1) the load of your typical pallet, and (2) the load of your heaviest pallet.

These numbers are crucial for use in step 5, as they help you calculate the appropriate load capacity for your racks. Going above the storage capacity limit is a serious safety issue, so be sure you get the weight correct.

Step #3: Measuring Pallets’ Frame Depth

Pallets’ frame depth is an important determinant for computing the space between the load beams. To ensure a perfect fit, you should subtract six inches from your pallets’ depth. Doing this allows your pallets to overhang the beams by about 3 inches on each side, enabling the beams to support the pallet’s entire weight.

“So, what’s the point in having such overhang?”, you may ask. Well, the answer is pretty simple. When it comes to load beams, their purpose is to lift your pallet weight, not the wire decking that is put on top of them.

Here’s an instance. Suppose you have a regular 48-inch deep pallet. To get 3 inches of overhang on each side, let’s subtract 3 inches from 48 inches, which is 42 inches. Thus, a 42-inch deep frame provides sufficient overhang for a conventional 48-inch pallet, making it the most widely used frame depth.

Besides the above figure, 48-inch and 36-inch are the next most popular pallet’s frame depth.

Step #4: Finding Pallet Rack Upright Sizes

Vertical storage is usually the most cost-effective storage solution to store more items in the same area. If done correctly, it can result in significant savings. Pallet rack uprights come in typical sizes, ranging from 8 feet to 24 feet. Among them, 12-feet and 16-feet are the most frequently used heights in the industry.

To choose the appropriate upright height, let’s consider the following aspects:

Assessing Your Ceiling Height

To begin, let’s measure the height of your warehouse ceiling height first. Allow about 18 to 24 inches of space between your goods and the ceiling or sprinklers. This helps you meet the fire rules and offer much-needed clearance.

For example, if your warehouse ceiling is 15 feet high, you won’t be able to install 16-foot pallet racks, although these racks are suitable for 20-foot ceilings. Make sure you know how high your ceilings are in every location where you wish to extend your storage vertically.

Going As High As You Can

Another suggestion is to go as high as you can, even if it provides you with redundant storage rooms. Why is that? Well, the installation costs of a 12-foot frame and a 16-foot frame are likely negligible. Yet, the replacement expense from a 12-foot frame to a 16-foot frame is significantly large.

Thus, as pallet racks are big investments for your warehouse, focus on future growth when deciding which racks to buy, and don’t go short just to save a few cents. But this suggestion may lead you to the next pointer.

Beware Of Going Too High

This sounds confusing and even contradictory, right? Well, let me explain. In addition to the warehouse ceiling, you should take into account factors like your forklifts’ maximum operational height. If the vehicle can reach a maximum of 10 feet, you will be unable to fully use 16-foot pallet racks until you modify your storage equipment.

Also, beware of the 12-foot threshold. Products placed above that limit are subject to high-piled storage concerns. When applying for rack permits, your city will assess your fire sprinkler system and the flammability of your goods. During that process, they may restrict how high you can go based on those two factors.

Planning for development is crucial. Just make sure you understand your constraints and which pallet racks you can fully utilize.

Step #5: Picking Pallet Rack Beam Dimensions

Each pallet rack beam is defined by its length and height (also known as “face size”). Among the two figures, beam length influences how many pallets you can place on each beam level. Beam lengths are generally measured in inches.

The most widespread beam length is 8 feet, allowing for the placement of two pallet rack standards of 48-inch by 40-inch pallets. If you want to hold up to three pallets of such dimensions, opt for the 12-foot beams. For more details on the relationship between pallet rack beam dimensions and their storage capacity, check out the table below:

| Beam Length | Beam Height | |||

| 3 inches | 4 inches | 5 inches | 6 inches | |

| 8 feet | 2,000 lbs | 4,000 lbs | 6,500 lbs | 8,000 lbs |

| 9 feet | 1,500 lbs | 3,000 lbs | 5,500 lbs | 7,500 lbs |

| 10 feet | 1,200 lbs | 2,500 lbs | 4,500 lbs | 7,000 lbs |

| 12 feet | 800 lbs | 1,800 lbs | 3,000 lbs | 5,000 lbs |

| Storage capacity per pair | ||||

Remember the two key figures mentioned in step 2? Feel free to look at them again now. Your pallet weight is the most important criterion in choosing the appropriate beam dimensions. Please note that beam capacities are always reported per beam level, which corresponds to each beam pair.

So, if you require a load capacity of 5,000 pounds or more per beam level, a conventional 8-foot beam is definitely what you’re looking for. If your pallets aren’t too heavy, a 12-foot beam would be a better option.

Also, don’t forget beams’ face size, which varies from 3 inches to 6 inches. For large capacity demands, use the 6-inch height. Ensure that the face size and beam length are appropriate for the capacity you need.

Extra Factors To Consider When Selecting Pallet Rack Sizes

In addition to the straightforward process outlined above, there are a few other factors that will influence your pallet rack selection. Some of them include rack types, rack decking choices, and rack accessories. Let’s explore these additional aspects below.

Pallet Rack Decking

Pallet rack decking refers to the material that is positioned on the racking system to sustain loads of various sizes and weights. When it comes to this aspect, there are a plethora of options you can browse, including:

- Bar grating: If you need to store large loads of goods, bar grating can be your ideal decking option. Despite being a bit expensive, this material is very durable, simple to clean, and can fulfill almost any load demand.

- Wire mesh: This is by far the most affordable decking material available. Wire mesh decking is installed on the beams, spanning the whole rack length, enabling you to clearly see what you’re storing. Besides being non-flammable, this decking type has a normal load capacity of 900–1,100 kg.

- Plywood: This material is ideal for holding lightweight products. Nevertheless, you should opt for other more durable options when it comes to storing heavy items. Also, the fire marshal may be concerned about plywood decks as they are combustible, which might cause you to fail an inspection.

- Corrugated steel: Like bar grating and wire mesh, corrugated steel allows water to pass through, making it a popular material among fire marshals. Pallet rack decks made of corrugated steel are often called punch decks and offer significant load capacity.

- Perforated steel: If you need a flat surface for your inventory, perforated steel decks can be the ultimate solution. These decks are often built with many welded supports to provide a large and smooth storage area. In addition, perforated steel comes with holes that enable water to flow through, which increases fire safety.

Pallet Rack Accessories

In terms of accessories, there are also many sorts that you can add to your inventory systems to increase their usefulness. Here are a few extensions that are worth your consideration:

- Pallet supports: These accessories offer support for the bottom parts of pallets. Normally, each pallet needs two pallet supports that share the same depth with its uprights.

- Safety netting: Often made from nylon or polypropylene, safety netting offers extra protection for your storage system across its numerous levels. You can install safety netting anywhere on the pallet racks to prevent goods from falling.

- Column guards: Also known as post protectors, these tools are excellent methods to safeguard your inventory systems from wayward forklift drivers or other warehouse accidents. These guards are often mounted either directly to the uprights or separately from the rack post.

- Floor shims: These metal shims are placed beneath the upright plates to help level the racks and keep them from swaying. They are a must to have when your warehouse floor is uneven.

- Row spacers and wall ties: The purpose of these accessories is to securely hold pallet racks at predetermined distances from warehouse walls or other racking rows. You should apply row spacers to each upright’s top and bottom sections in a racking row when the upright height exceeds six times the depth.

Pallet Rack Configurations

Besides pallet rack decking materials and accessories, it’s critical to pick the suitable racking configurations for your facility. Each rack type may have its unique dimensions. Thus, deciding on the right pallet types can help you select their sizes more quickly.

- Selective pallet rack: This is the most popular warehouse racking type, with horizontal beams linking directly to vertical uprights. Its open design makes the selective pallet rack highly accessible.

- Drive-in pallet rack: This racking system is unique for its optimization of the warehouse’s ground area by using the LIFO method. This layout allows forklifts to travel inside the system easily and safely.

- Drive-through pallet rack: While drive-in systems are suitable for the LIFO technique, drive-through solutions are better suited to the FIFO method since they utilize two separate lanes for both loading and unloading products. As the name implies, forklifts can drive through the system from one end to the other.

- Push-back pallet rack: Similar to the drive-in system, the push-back pallet rack also provides high-density storage in a LIFO configuration. All pallets are placed on a cart. Each time a new pallet is added, the first one will be pushed back towards the rear of the system.

- Pallet flow racking: This system features inclined wheels or rollers that enable pallets to move from the rear aisles to the front aisles. It utilizes the FIFO method, meaning that when the front pallet is emptied, the following load automatically moves into the position to improve picking efficiency.

Conclusion

In conclusion, choosing the right pallet rack sizes is crucial for maximizing your warehouse storage space and ensuring its efficiency. Understanding the available options empowers you to make an informed decision more quickly and accurately.

This article has provided a straightforward 5-step process that you can utilize whenever there’s a need to install new pallet racking systems. There are also sections about extra considerations that can help you pick more well-suited dimensions.

With the right pallet rack dimensions tailored to your unique storage requirements, you can unlock your warehouse’s full potential and gain a competitive edge in today’s dynamic business landscape. Thanks for reading!