If you manage a warehouse, are a logistics specialist, or own a business, you know how important it is to make the most of your storage space and be more efficient. Designing pallet racking layout effectively ensures proper use of the warehouse space.

Pallet racking is one of the most common and versatile storage solutions for warehouses of all sizes and industries. In this post, I’ll guide you through the process of designing the most suitable pallet racking layout to meet your specific requirements.

Why Pallet Rack Layout?

Pallet rack layout is the way you arrange your pallet racks on your warehouse floor. It affects how you store, access, and move your inventory, as well as how you utilize your available space. A good pallet rack layout can help you:

Benefits/ Advantages of a Well-Designed Pallet Racking Layout

- Increase your storage capacity and density

- Reduce your operational costs and waste

- Enhance your safety and ergonomics

- Streamline your workflow and productivity

- Adapt to changing demand and inventory levels

As you can see, pallet rack layout is not something you can ignore or take lightly. It can make or break your warehouse performance and profitability. That’s why you need to plan carefully and design strategically before you install or modify your pallet rack system.

5 Steps to Create a Perfect Warehouse Racking Layout

So how do you create a perfect warehouse-racking layout? I’ve outlined five simple steps below:

1. Analyze Your Inventory And Throughput

To efficiently design your pallet racking system, begin by analyzing the products you store. Consider factors like product type, quantity, frequency of receiving and shipping, dimensions, and weight.

This information will guide your decisions regarding the type, size, and quantity of pallet racks needed, as well as the most suitable loading and picking methods for your operations.

2. Measure Your Warehouse Space And Constraints

The second step is to measure your warehouse floor. Measure the height, width, and length. Also, think about the shape. Also, you need to think about any obstacles. These could be things like columns, doors, or windows.

You also need to consider where the sprinklers, lights, and vents are. This will help you know how much space you have for your pallet racks. It will also help you figure out the best way to arrange them.

3. Choose Your Pallet Rack System And Accessories

The following step is to pick the best pallet rack system for your inventory and throughput. There are many types of pallet racks, like selective pallet racking, drive-in/drive-through pallet racking, push-back pallet racks, pallet flow racking, radio shuttle pallet racks, and so on.

Each one has its pros and cons depending on how you need to store things and what you like. You also need to choose the right accessories for your pallet racks, like pallet rack beams, pallet rack uprights, wire mesh decking, safety bars, row spacers, column protectors, etc. The durability, longevity, and functionality of your pallet racks are all determined by these factors.

4. Design Your Pallet Rack Layout Using Software Or Tools

Step 4 is to design how you will set up your pallet racks. You can use computer programs or tools to help you picture and make the best use of your space. There are a lot of programs and tools you can use. Like AutoCAD, SketchUp, and LibreCAD.

You can also talk to a professional pallet rack designer or seller who can give you ideas and solutions tailored to your needs. The goal is to come up with a plan that lets you store as much as possible in the smallest space while still being able to move around easily.

5. Installation of pallet racking according to the designed pallet racking layout

The final step is to properly install and maintain the pallet rack according to the designed pallet rack layout drawings. Follow the manufacturer’s instructions and safety guidelines when installing pallet racking.

Regularly inspect and maintain your pallet racks to make sure they’re performing well. Also, review and update your pallet rack layout as needed to reflect any changes in your inventory.

Factors to Consider for Pallet Racking Layout

Besides the steps mentioned above, there are also some factors that you need to consider when designing your pallet rack layout. These include:

- Your budget: How much money can you afford to spend on your pallet rack system? This will affect the type, size, quantity, and quality of the pallet racks that you can buy.

- Your growth: How do you expect your business to grow in the future? This will affect how flexible and scalable your pallet rack system and layout should be.

- Regulations: What are the local codes and standards, such as fire and safety codes that apply to your warehouse? This will affect the safety and compliance of your pallet rack system and layout.

- Environment: What are the environmental conditions that affect your warehouse? This will affect the material and design of your pallet rack system and layout. The temperature, humidity, lighting, and ventilation of your warehouse may require special rack materials or coatings to prevent corrosion, rust, or damage.

- Building structure: The shape, size, and layout of your warehouse will affect the rack placement and orientation. You should consider the ceiling height, column spacing, floor loading, and any obstacles that might interfere with the rack system.

- Pallet size and type: The dimensions and weight of your pallets will determine the rack depth, height, and capacity. You should also consider the type of products you store, such as date-sensitive, fragile, or bulk items.

- SKU / pallet count: The number and variety of your SKUs and pallets will influence the rack density and configuration. You should aim to maximize the storage space and minimize the aisle space while ensuring easy access and visibility of your inventory.

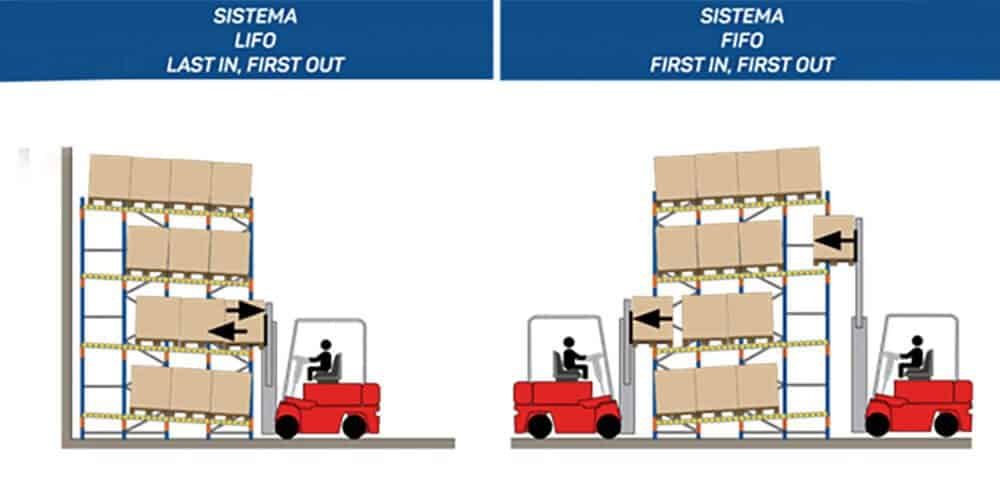

- Order of inventory retrieval: Whether you need a LIFO (last-in, first-out) or FIFO (first-in, first-out) system will affect the type of rack system you choose. For example, selective pallet racks are suitable for both LIFO and FIFO, while drive-in racks are more suited for LIFO.

- Product flow/accessibility requirements: The frequency and volume of your product movement will determine the rack accessibility and throughput. You should design your rack system to optimize the product flow and reduce the travel time and distance for your workers and equipment.

- Material handling equipment: The type and size of your forklifts, pallet jacks, conveyors, and other equipment will influence the rack design and aisle width. You should ensure that your equipment can safely and efficiently maneuver and load/unload your pallets.

LIFO vs. FIFO in Pallet Racking Layout

An important factor that you need to consider when designing your pallet rack layout is the inventory rotation method that you use.

There are two main methods: LIFO (last in, first out) and FIFO (first in, first out). LIFO means that the last pallets that you load are the first ones that you unload, while FIFO means that the first pallets that you load are the first ones that you unload.

Each method has its pros and cons depending on your inventory type and turnover.

When FIFO Is Suitable

- Products with a short shelf life that expire or deteriorate quickly

- Products with a high demand and turnover rate

- Products that require strict tracking or tracing

- Products with a high variety and low volume

When LIFO Is Suitable

- Products with a long shelf life and do not expire or deteriorate quickly.

- Products with low demand and turnover rate.

- Products that do not require strict tracking or tracing.

- Products with low variety and high volume.

Depending on your inventory rotation method, you need to choose the right type of pallet rack system and layout for your warehouse.

Conclusion

To summarize, the importance of designing a pallet rack layout that’s both efficient and effective cannot be overstated. It plays a major role in optimizing warehouse storage capacity, cutting costs, boosting safety, and making operations run smoother.

By following the five steps in this article, and choosing the appropriate pallet racking system based on your business’s needs, you can create a layout that saves space, and improves inventory management.

By investing in a well-designed pallet rack layout, you can transform your storage space into a strategic asset that supports your business growth and success.