Pallet Racking Quote Reference

Guangdong Lijin Storage Equipment Co.,Ltd. Pallet Racking Quotation Reference

Factory Address: NO.6 Chongde Road, Cuntou, Hengli Town, Dong Guan City, Guang Dong Province, 523881 China

Tel: +86 – 769-81769090 Mobile Number: +86 13544633933

Email Address: michelle@lracking.com Contact Person: Michelle Zheng

| Items | Components | Specification (mm) | Qty | Unit | Unit Price ($) | Total Price ($) |

|---|---|---|---|---|---|---|

| 1 |

Upright frame

Upright frame

|

H6000*D1200*90*70*1.5 | 1 | SET | 1 | 1 |

| 2 |

Rack beam

Rack beam

|

L2700*110*50*1.2 P‘ type | 1 | PCS | 1 | 1 |

| 3 |

Rack board

Rack board

|

L900*D1200*T0.7(with 3 reinforcement under below) | 1 | PCS | 1 | 1 |

| 4 |

Upright protectors

Upright protectors

|

L200*150*300*1.5 | 1 | PCS | 1 | 1 |

| 5 |

Guardrail

Guardrail

|

L1000*50*300*1.5 | 1 | PCS | 1 | 1 |

| 6 |

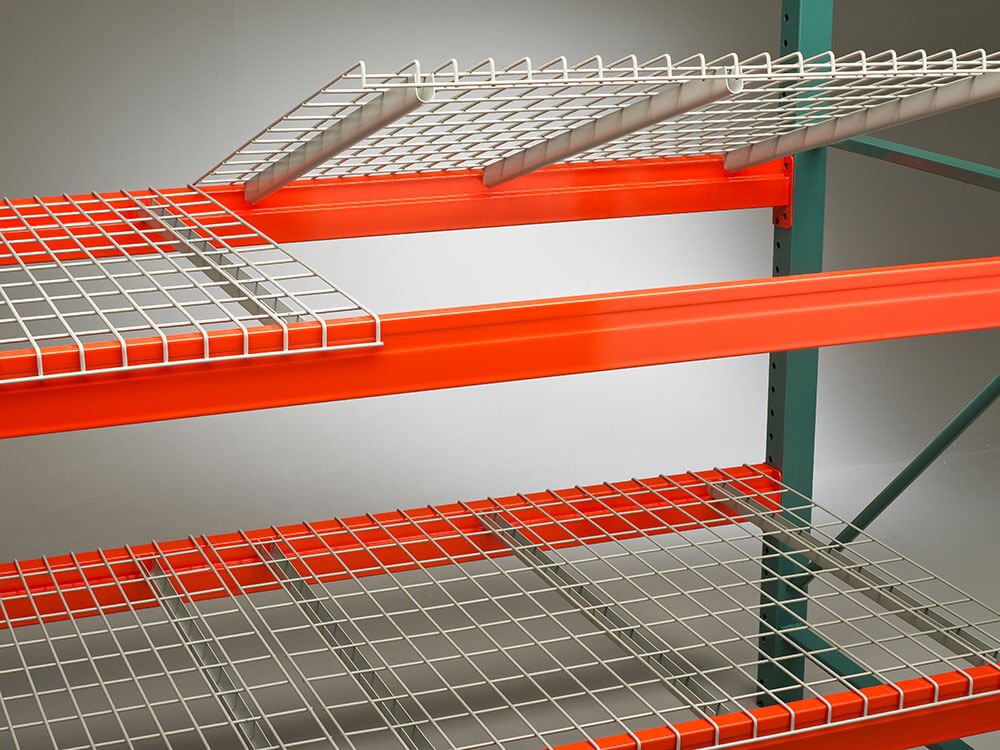

Wire mesh decking

Wire mesh decking

|

L1200*D1100*1.0 | 1 | PCS | 1 | 1 |

| Total amount |

|

|

6 | PCS | $6 | $6 |

Remarks:

1. The above price is FOB.

2. The expiration period of this quotation is 15 days.

3. Exchange rate of USD:RMB=1: 7.1

Commercial terms:

1.Material: Q 235 B Cold rolled steel;

2. Features: Easy to assemble and disassemble; Appearance: Electro Static Dusting Spray;

3. Quality Guarantee: 5 Years from the delivery date;

4.Origin: Dongguan,China;

5.Lead Time : 30Work Days (beside 6th~22th, Feb. this is our holiday for CNY);

6. Payment: 40% T/T in advance and balance 60% before delivery;

7. Packing: All the component is packed by air bubbles.

8. Factory Audit (Acceptable or Not): Acceptable;

Superficial treatment:

1. Storage rack surface adopts epoxy resin static paint finishing treatment, the thickness of the coat is 60-80 microns.

2. Spray process: remove exterior oil→washing→acid cleaning to remove the rust→washing→parkerising→washing by high pressure→parch→static paint finishing→solidify under high temperature.

Features:

1. The beam allowable flexivity length is 1/200, upright max. allowable flexivity height is 1/1000.

2. Upright hole distance is 75mm, and the beams can be adjusted height arbitrarily, a particular rhombus hole design can be; used covertly. There are safety bolts on the beam to prevent moving the beams when the fork truck is raising and dropping.

3. Superficial process: epoxide resin static paint finishing treatment, test the hardness by 2H pencil without scratch, racking superficial is acid and alkali-resistant, and the thickness of the coat is about 100-80 microns.