Pallet racking is a part and parcel of various industrial sectors and their warehouses, however, ensuring safety with pallet racking is always very important. When it comes to installing the pallet racking system, the most important thing is to ensure that they are safe for the workers and surroundings.

Some of the aspects of pallet racking safety that you must be aware of are discussed in this guide below so let’s take a look.

Understanding Pallet Racking Safety

What is Pallet Racking?

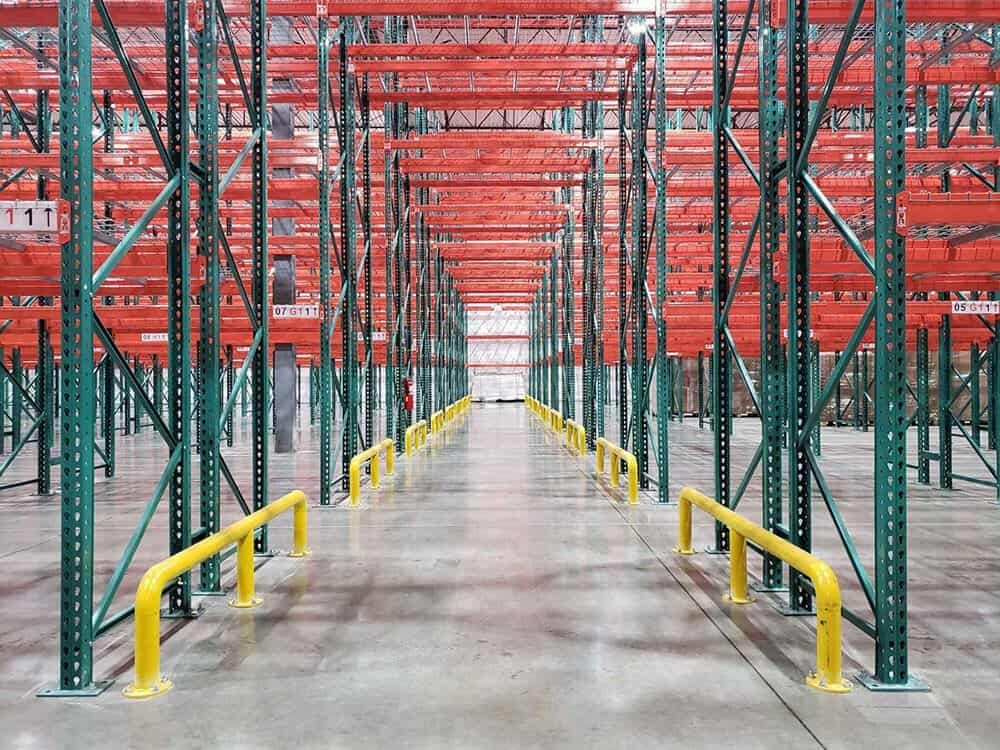

Pallet racking is a storage system that is implemented in a warehouse to store and organize palletized goods in an efficient way. It comprises horizontal beams and vertical frames that create shelves allowing pallets to be accessed and stacked conveniently.

Pallet racking is quite popular for use in warehouses and helps to maximize the overall storage space and offers quick access to the goods. The structural integrity and stability of a pallet racking system are very important for safety. The design of the pallet racking system must be capable of supporting weight and distributing the pallets without collapsing.

Common Risks and Hazards

There are various risks and hazards associated with pallet racking and some of these are given below followed by the consequences of such risks.

- Overloading is placing more weight on the pallet racks than they can hold which may cause a risk.

- Lack of proper assembling of the racking system is also a reason which leads to accidents with the pallet racking.

- During the process of material handling, the collision may result in serious hazards.

- When loads are not secured properly, they lead to a risky situation.

- Failure to maintain the racking systems timely and not keeping a check on them is also a cause of hazard.

Some of the consequences of the potential risks and hazards may include injuries due to overloading and structural failures leading to the falling of pallets. Collapsing of the pallet racking also damages the goods and disrupts the supply chain.

Pallet Racking Safety Tips

Some of the pallet racking safety tips are given below which must be implemented in all the warehouses consisting of a pallet racking system.

Installation and Design

The installation of the racking system must be carried about by professionals who know about the manufacturer guidelines and are even aware of the industry standards.

The pallet rack design needs to be sufficiently capable of even distribution of weight across the beams so that the stress on the individual components can be avoided. There must be some space between aisles and racks which allows the reachability of forklifts without any collisions.

Regular Inspections and Maintenance

You can develop a regular schedule for inspection which can be monthly or weekly depending on the usage of the racking system.

It helps to identify any indications of rusting, loose screws, or any other wear and tear signs. If you come across any signs of damage make sure to repair them to prevent any hazard.

Loading and Unloading Best Practices

Ensure the even distribution of weight and do not overload the racks to avoid collapsing racks. Also, employees must be trained in loading and unloading techniques in order to avoid hazards and accidents.

Protective Measures

Barriers and guardrails when installed along the racking system protect from potential risks, pallet racking decking can be chosen to secure pallets and help prevent items from falling off the pallet racks. Also, you must label the weight limits so that the racks are not overloaded.

Don’t Overload Racking

Strictly adhere to weight limits which are given by the racking manufacturer in order to ensure that the structure of the racking system is maintained and does not overload the pallet racks.

Warehouse Safety Suggestions

The installation of pallet racking systems is commonly observed in warehouses and some of the warehouse safety suggestions that may prove to be helpful are given below:

Employee Training and Awareness

Employee training sessions are very important to keep them updated on the safety procedures and equipment use, these training sessions also allow them to stay updated with the emergency protocols. Employees must be encouraged to report unsafe conditions and develop a culture of safety.

Emergency Preparedness

Emergency preparedness is very important and in this case, evacuation routes, emergency response plans, and procedures for dealing with fires and collapses of racks must be in place. The employees should also practice emergency drills on a regular basis so that they can develop the efficiency to respond during a crisis.

Ergonomics and Workflow Optimization

The design of the workstations should be optimized in a way that the need for bending, reaching, and lifting excessively is reduced as all this has a chance of leading to injuries. Also, the products must be organized in a way that they can be accessed immediately with ease so that the risk of accidents can be minimized.

Warehouse Safety Checklist

In order to ensure that the warehouse is functioning without any risks, the warehouse safety checklist must be followed as given below.

Daily Safety Checks

Daily safety checks must be carried out in order to ensure that a safe working environment is maintained. You can ensure that the aisles are clear of debris and obstructions so that the movement of staff and equipment can be carried out smoothly.

Also, racking systems must be checked for any visible damages like loose screws or bent frames as these issues may lead to stability risks. Daily checks of the emergency exits to ensure they are kept unobstructed so that in case of any emergency quick evacuation is possible. Equipment like first aid kits and fire extinguishers also should be verified and checked for functionality.

Weekly and Monthly Safety Checks

Weekly and monthly inspections comprise a detailed analysis of the warehouse for assessing any risks or potential hazards. During the weekly and monthly analysis, the racking system’s stability is looked after and any signs of uneven load distribution are addressed.

Expiry dates of safety equipment are checked and if replacement and services are needed these equipment are replaced or serviced. The inspection of flooring is also important to check for any uneven surfaces that may cause tripping.

Load capacity labels are assessed to see if they are in good condition and offer accurate information. Also, employee training records should be checked to confirm that relevant timely training is attained by them.

Record Keeping

It is very important for the safety of a warehouse to ensure that a detailed record of maintenance and inspections is present. These detailed records comprise the date of inspection, issues that have been found, measures for correction, and signatures of people who conducted the checks.

Appropriate documentation offers to track the safety performance over a period of time and also helps to identify issues that keep on recurring. By regular review of these records, safety protocols can be achieved and addressed timely.

ANSI Pallet Racking Safety Guidelines

ANSI 16.1 comprises pallet rack safety regulations for all types of industrial racking systems which comprise pallet racks, stacker racks, or moveable shelves. Some of the important aspects of these safety guidelines are as follows:

Damaged Components Replacement and Repairs

Damaged components require replacement by qualified professionals and a recommended and documented procedure shall be followed in this case. The repair components should be strong enough to match the strength of undamaged components.

The process of repairing which comprises assessment, design, and installation should be looked after by a quality professional rack engineer. The assessment of the rack repairs must also address the load capacity that can be safely held by repaired racks.

Owner Maintenance

The structural integrity of the racking system installed must be maintained by the owner and the proper maintenance and operation procedures must be assured. The damages should be inspected regularly and any damaged part of the rack should be freed up from the load.

Owners should not attempt repairing the racks on their own despite having sufficient resources and skills and rather a proper engineering oversight should be present. Unless there is a proper engineering oversight, the repairs would not be considered safe for the warehouse racking system.

Review of Reconfigurations, Alterations, and Additions

Every type of racking reconfiguration, addition, and alteration should be evaluated by a quality engineer so that they can assess that the changes made meet the actual installation and its exact requirements. You can hire a licensed professional engineer to take a look at the proposed configuration for the racking system to check if they are acceptable or not.

Damage of Rack

In case of any visible damage to the racking system, the portion of the rack should immediately be unloaded unless the damaged portion is replaced or repaired. You can contact a qualified engineer to carry out an evaluation of the effects of damage that causes disruption in the structural integrity of the rack. After evaluation and repairs, once the racking system is competent enough then only it should be used again.

OSHA Safe Warehouse Guidelines

OSHA stands for the Occupational Safety and Health Administration which has provided guidelines for the purpose of ensuring a safe working environment for the employees. The regulations of OSHA which pertain to employees working in an environment surrounded by a racking structure comprise the following:

According to OSHA General Duty Clause section 5(a)(1), employers are bound to offer their employees a working space that is free from all types of recognizable risks that may cause any serious harm or death to employees.

Get Professional help from Lracking

The guide above highlights the significance of installing safe and risk-free pallet racking systems, if you are also inclined towards sourcing a customized pallet racking system for your warehouse, you can get in touch with Lracking.

Lracking provides you with a customized version of the racking system which is according to your specifications and space. They ensure safety as they follow the safety guidance while they design and manufacture these racking systems.