Picking the right pipe storage rack type for your warehouse is a critical task, as it offers a secure and orderly means to store and transport heavy materials. From horizontal and vertical racks to cantilever and other heavy-duty alternatives, each pipe storage rack design has its own set of characteristics designed to meet specific demands.

This article will equip you with foundational knowledge about industrial pipe storage racks, including their composition, applications, and key benefits. It also presents numerous pipe storage rack ideas and discusses important factors to consider when selecting the best option for your needs.

Pipe Storage Rack 101

A pipe storage rack is a specialized inventory solution to effectively store, handle, and manage numerous pipes and tubes. Its main function is to create a secure and neat warehouse environment for holding pipes, making them conveniently accessible and reducing the danger of damage.

There are a plethora of pipe storage rack designs to house pipes of diversifying dimensions, lengths, and materials in an organized way. The following parts will delve into more detailed aspects of pipe storage racks, from their elements to industry-specific applications.

Pipe Storage Rack Composition

Also known as warehouse pipe racks, these inventory structures comprise a series of horizontal beams spanning the pipe length, steel supports, and multiple separators that are spaced equally, around 20 feet apart.

These separators provide compartments for vertical storage of pipes of varying diameters, thereby optimizing inventory space while being conveniently accessible. Additionally, the struts join the beams to provide stability and rigidity.

Pipe Storage Rack Applications

Pipe storage racks are widely used in a variety of sectors, including petrochemicals and power plants. Take the petrochemical industry as an example. You can easily see pipe storage racks in these warehouses and facilities to support pipes, cable trays, insulation, and equipment, ensuring that everything is safe and efficient.

These storage solutions are also useful assets in other industrial warehouses to facilitate the secure routing of cables and pipes. The more you explore and learn about pipe storage racks, the easier it is for you to pick the ideal racking type for your facility.

Key Advantages Of Pipe Storage Racks

There’s a reason why many warehouse managers trust and utilize pipe storage racks. The following are some of these structures’ benefits you will have when employing them in your inventory facility:

- Optimizing space utilization: Pipe storage racks can maximize your warehouse’s vertical space, thus freeing up precious floor footprints for other processes and enhancing overall organization around the facility.

- Offering quick accessibility: Since pipes and cables are systematically arranged in these racking structures, warehouse workers can easily identify and collect required items, thereby decreasing downtime and enhancing efficiency.

- Augmenting warehouse safety: Besides the enhanced accessibility and warehouse space utilization, pipe storage racks also lower the likelihood of accidents by reducing tripping and sliding dangers. As a result, these solutions facilitate a safer working environment.

- Protecting pipes better: It’s pretty evident that pipes and tubes held by racks are better safeguarded as these inventory solutions keep your products from hitting the floor or hard surfaces, hence reducing the possibility of dents, scratches, and other threats that can jeopardize their integrity.

- Highly customizable: One key benefit that sets pipe storage racks apart is their customizability. In other words, you can easily configure them to store pipes of different lengths, diameters, and weights. This feature enables businesses to tailor these storage solutions to their exact needs.

- Improving storage capacity: Pipe storage racks are built to last thanks to the use of durable and solid materials like industrial steel. Thus, they are capable of holding a large number of pipes, which is equivalent to higher inventory capacity.

Exploring The Top 5 Pipe Storage Rack Ideas

Now that you’re familiar with what pipe storage racks are, it’s time to delve into their various configurations. The below part will walk you through the top five pipe storage rack designs that most warehouses prefer.

#1: Vertical Pipe Storage Racks

The first pipe storage rack design is a great solution for storing longer materials, such as pipes and sheets, by keeping them upright. These vertical racks optimize storage capacity while also allowing for quick, efficient selection without the need for ladders.

Many warehouse professionals favor vertical pipe storage racks as they are cost-effective and easy to build, thereby maximizing floor space and providing simple access to items. They also utilize dividing mechanisms to prevent product damage while ensuring secure and transparent inventory.

PROs:

- Maximizing the warehouse’s vertical space.

- Preventing damage that may happen to the stored pipes.

- Providing easy and quick accessibility to pipes.

CON:

- Limited to upright inventory.

#2: Horizontal Pipe Storage Racks

The following pipe storage rack design utilizes horizontal beams and supports to provide a level, accessible platform for storing long pipes. These steel racks usually consist of a number of parallel compartments that run horizontally, enabling pipes to be placed flat.

Compared to their vertical counterparts, these horizontal racks take up more floor space. However, their design allows for simple organization and access without the need for ladders, making them suitable for warehouses where footprint is less of an issue and rapid, easy recovery of long pipes is required.

PROs:

- Facilitating easy organization of stored pipes.

- Offering accessibility without ladders.

- Well-suited for long pipes.

CON:

- Occupying more of the warehouse’s floor space.

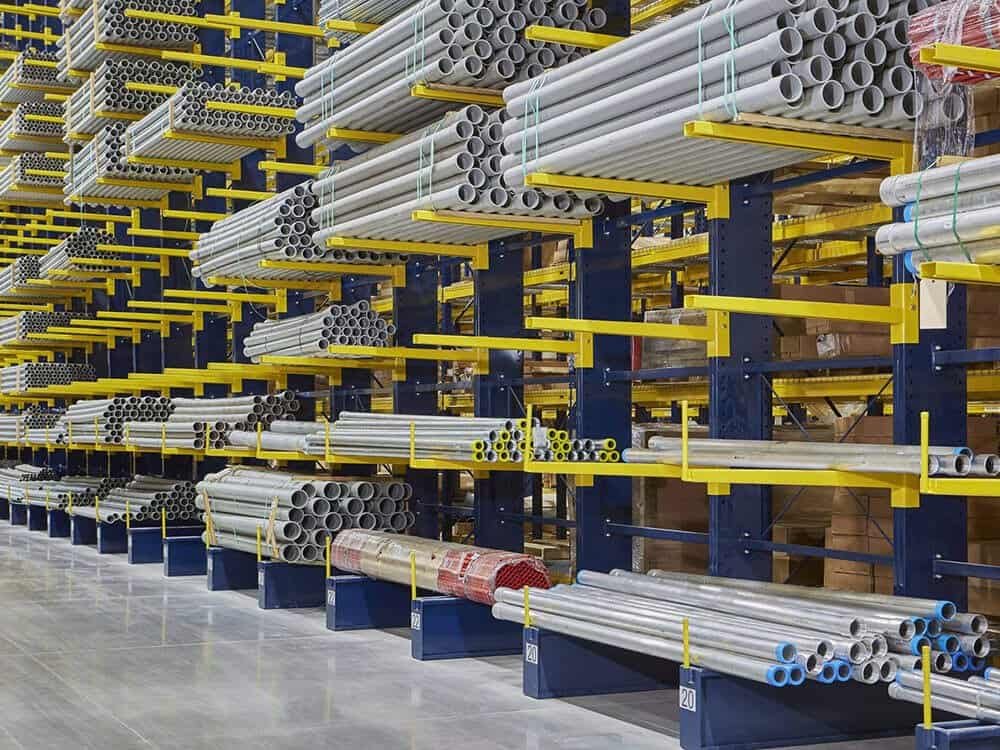

#3: Pipe Storage Cantilever Racks

Comprising vertical columns and movable horizontal arms, pipe storage cantilever racks can carry long pipes of various lengths, weights, and materials (such as PVC pipe storage racks). These arms are easily adjustable up or down to fit a wide range of material sizes. Moreover, with the pipes loaded and unloaded from one side of the rack, making storage and retrieval more accessible.

One major strength of cantilever racks is their large weight capacity, allowing them to handle heavy pipes both effectively and safely. This characteristic makes them ideal for industrial settings like warehouses. Yet, due to their sturdy and customizable structures, these racks have higher installation costs than other industrial pipe racks.

PROs:

- Ideal for holding long items.

- Having adjustable arm levels.

- Providing a high weight capacity.

CON:

- Requiring relatively high installation costs.

#4: Stackable Pipe Racks

Although stackable pipe racks have vertical stacking height constraints, limiting the total quantity of items that can be stored, these inventory solutions offer many substantial benefits. The most brilliant one is their stacking mechanism, which enables optimal use of space and reduces footprints in warehouses with limited floor space.

Plus, their modular architecture allows them to be very versatile and easily relocated to other spots in the facility. This effortless relocation is the top reason why warehouse managers choose stackable pipe racks: to meet their constantly changing storage demands.

PROs:

- Saving footprint when employed via the stacking mechanism.

- Simple to relocate the racks to other spots.

- Highly flexible.

CON:

- Facing limited vertical stacking heights.

#5: Rolling Pipe Storage Racks

If you’re searching for mobility and adaptability in a pipe storage rack design, then rolling racks are your exact answer. Featuring casters or wheels for convenient movements, rolling pipe storage racks are useful in circumstances where pipes must be routinely moved from one spot to another.

Despite their many benefits, these racks pose certain stability issues. Their wheels and mobility nature might make them less stable than permanent racks, particularly when hauling large cargo. Therefore, proper use and management are required to reduce these dangers.

PROs:

- Mobile and versatile.

- Easy to reposition around the warehouse.

- Maximizing accessibility.

CON:

- Posing certain stability risks.

Crucial Factors When Choosing Pipe Storage Racks For Your Warehouse

Knowing the many types of pipe racks for sale is only half of the equation. In order to pick a well-suited option for your inventory facility, you’ll need to go over a set of essential factors to make your decision-making process more effective.

Warehouse’s Available Floor Space

When selecting pipe storage racks, make sure to assess the available floor space in your warehouse. This factor is essential, as it can narrow down your options immediately. For example, vertical and stackable pipe racks are optimal choices for smaller facilities as they optimize vertical space.

In contrast, cantilever and horizontal pipe storage racks may require additional floor space, but they provide more convenient access to long pipes and tubes. Briefly speaking, by accurately measuring your warehouse layout, you can pick the most appropriate pipe storage rack type more easily.

Pipe Size And Weight

Another important consideration when browsing pipe storage rack ideas is your stored pipes’ characteristics, specifically their dimensions and weight. Long, heavy pipes are best kept in heavy-duty pipe storage racks like the cantilever type. However, lighter, shorter pipes are great when held by vertical or stackable racks.

Make sure to observe and understand your pipes, as those are valuable inputs for your pipe rack selection. Besides the pipe size, don’t forget to purchase racks that have enough weight capacity. You never want to witness the consequences of overloading your inventory solution!

Loading And Unloading Requirements

If you’re still unsure of which pipe storage rack design to choose, think about your loading and unloading operations. If you often move pipes, rolling pipe storage racks may help you handle them more quickly and efficiently.

In situations where frequent access is important, you should opt for cantilever or horizontal racks. However, if you’re facing footprint constraints, then utilize the vertical option, as this alternative maximizes vertical space at the expense of easy accessibility.

Environmental Conditions

Environmental conditions where you place your racks also play an important role in your decision-making process. If your operations require positioning your storage solutions outside, make sure to opt for outdoor pipe storage racks, as they use weather-resistant materials like galvanized steel.

For indoor racks, although they may not need as rigorous protection, they should still be sturdy and appropriate for the warehouse environment. Therefore, consider indoor racks with protective coatings to prevent corrosion and damage while also preserving the durability and quality of stored pipes.

Safety Regulations And Industry Standards

The most crucial aspect when choosing any storage solution is safety, and pipe storage racks are no exception. Ensure that you follow all applicable safety requirements and industry standards. In other words, your chosen racks must fulfill load capacity, stability, and construction quality criteria.

Additionally, proper labeling of your pipes with essential information like size, material, and application is necessary, as this practice allows your warehouse employees to easily identify the pipes they want and reduce mistakes. If you’re unsure how to do this, consult with experts and utilize their insights to facilitate a secure storage environment.

Cost Considerations

You can only realize your plans for pipe storage racks when your budget allows, as cost is always an important consideration. You should be wise with your money and choose an option that is both quality and functional.

Investing in high-quality racks can be expensive up front, but it will be cost-effective over time due to the solutions’ durability. Also, you’ll optimize your expenses in the long run, as these racks require less maintenance compared to typical structures.

Essential Tips For Installing And Maintaining Pipe Storage Racks

Once you’ve selected your ideal pipe storage rack, it’s important to put extra effort into learning a handful of essential tips to facilitate their safe and easy utilization. The following is a collection of those tips, just for you!

Site Preparation And Rack Assembly

Thorough site preparation and careful construction are required for a successful pipe storage rack installation. First, analyze your warehouse area to find the best location, taking into account accessibility, weight capacity, and workflow efficiency.

To maintain a safe working environment, remove any impediments from the designated spot. Also, follow the manufacturer’s instructions for building the racks and pay special attention to precisely align connectors and securely tighten bolts. Another important aspect is to anchor the structure to the floor or wall for optimal stability.

After assembly, check for damage or misalignment and test their load-bearing capability to verify your pipe storage racks can withstand the desired weight.

Loading And Unloading Best Practices

Maintaining the integrity of pipe storage racks requires adhering to optimum loading and unloading techniques. To do this, train your warehouse staff on the correct handling procedures, stressing the importance of staying within weight limitations and maintaining equal load distribution.

One useful practice is to arrange heavy pipes on lower levels and lighter ones on upper levels to provide top-notch stability to the structure. In addition, always use proper equipment, such as forklifts or cranes, to safely transport heavy or lengthy pipes. This helps lower the possibility of accidents and enhance your racks’ longevity.

Routine Inspections

Another necessary tip is to schedule frequent checkups to detect symptoms of wear, damage, or misalignment in your pipe storage racks. Look for corrosion, bent components, or loose bolts, and repair them right away. Also, don’t forget to inspect the anchor points to verify that the racks are firmly fixed to the warehouse floor or wall.

Periodically test the load-bearing capability to ensure that your pipe storage racks can still sustain the specified weight. Regular audits also help ensure that the pipes are appropriately organized, positioned, and labeled for efficient handling.

Proactively keeping records of inspections and maintenance operations allows you to monitor the state of your inventory systems over time and resolve any possible issues before they become critical.

Are Pipe Storage Racks Suitable For Outdoor Applications?

The answer is a big yes! Pipe storage racks are certainly suitable for outdoor use. However, although most of these structures are steel pipe storage racks, this seemingly durable material is not totally weatherproof since rain, wind, and snow may erode its look, surface hardness, and overall integrity over time.

To overcome this issue, many pipe storage rack manufacturers intentionally build their pipe storage racks from stainless steel or apply protective coatings. Powder-coating the steel or galvanizing it with hot zinc prevent the material from being oxidized when placed outside, thus ensuring your racks can survive severe climatic conditions while keeping the stored pipes intact and accessible.

Conclusion

In summary, pipe storage racks are vital for warehouses that work with tubes and pipes of various diameters. They offer an economical storage option while also optimizing inventory space and safeguarding employees from hazards.

When selecting a pipe storage rack design, consider the kinds and sizes of pipes you want to store. In addition, examine the available area, weight capacity, and any unique environmental conditions that the rack may experience.

To utilize the pipe storage racks safely and efficiently, make sure you fully understand the pipe storage rack manufacturers’ regulations and weight capacity standards. Also, conduct regular audits and maintenance to spot and address any possible safety issues as soon as they arise.