If you think that shelf and rack are two interchangeable terms, think again! They may serve the same purpose of storing goods in an organized way, yet these two storage devices are actually different in many ways.

This article will take you on an exciting adventure where shelves and racks take the spotlight, weaving their unique tales in your warehouses. Despite the common mix-up of these terms, this article is your roadmap for clarification.

Understanding the similarities and differences between rack and shelf will be your key to making informed choices. Without further ado, let’s embark on this storage journey right away!

Defining A Rack

Rack is a popular storage solution capable of holding heavy and bulky items in a neat way, thanks to its sturdy structure with the support of aluminum or steel poles and beams.

Different Rack Types

There are numerous varieties of racks available on the market, with each serving a distinct function. Let’s discuss a few of the most fundamental rack types below:

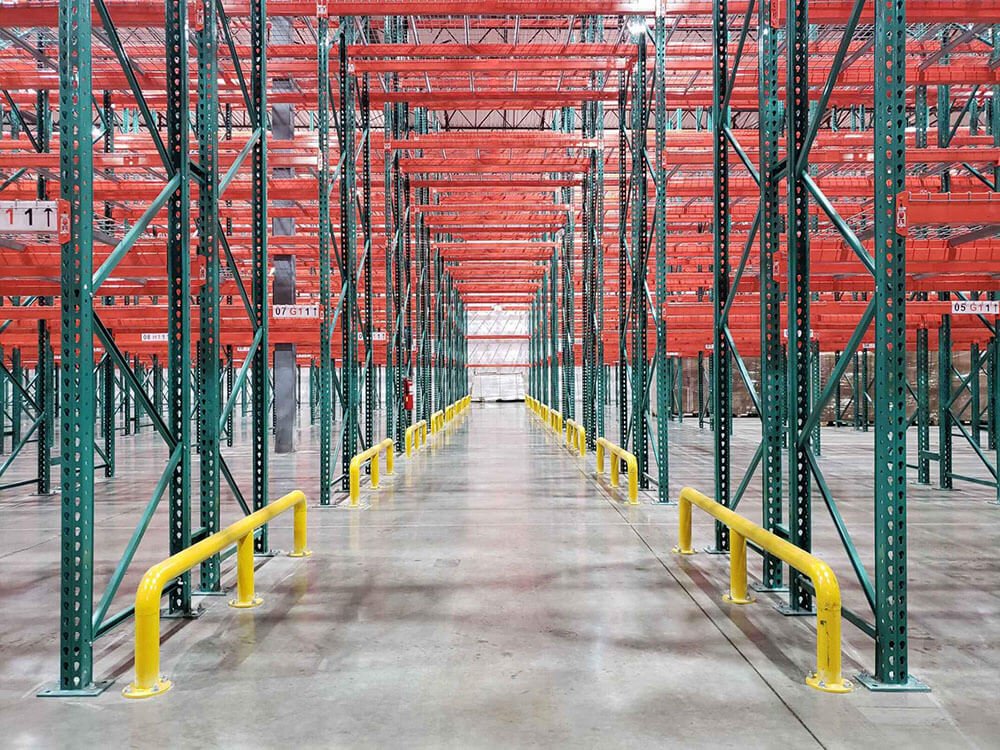

Selective Pallet Racking:

Not only is it the most affordable option, but selective pallet racking is also the most popular choice in many warehouses. Available in various sizes and height customizations, this racking option allows you to store pallets neatly and easily.

The best thing about selective pallet racking is that it provides direct access to each pallet in your storage facility, rendering you the ability to pick and retrieve items effortlessly.

Push-Back Pallet Racking:

It is safe to say that push-back pallet racking is a brilliant way to optimize warehouse space and eradicate the need for heavy forklifts. It works perfectly for “last in, first out” (LIFO) storage systems.

When a new pallet is loaded on this rack type, it will occupy the front position and push subsequent pallets toward the other end of the rack. When you unload the outside pallet, the remaining pallets in that lane will advance back to the front.

Drive-In Pallet Racking:

Drive-in racks are another exceptional option for LIFO storage procedures, where the final pallet loaded is the first available for retrieval. This rack variety requires the least space for aisles, as it only needs one for both the entry and exit of forklifts.

Therefore, warehouses with limited floor areas will benefit the most from utilizing drive-in pallet racking. However, as forklifts have to access the inner areas of the racks, ensure that your forklift drivers are skilled enough to prevent unnecessary accidents.

Pallet Flow Racking:

If drive-in racks work well with LIFO systems, pallet flow racking (or gravity flow racking) is the ideal choice for “first in, first out” (FIFO) configurations. Each lane of this racking variety can hold up to twenty pallets in depth to facilitate warehouse space optimization.

Thanks to the beds of rollers equipped with centrifugal brakes, pallet flow racking allows for pallets loaded on one side to be easily retrieved on the other side. This setup helps avoid warehouse accidents, as forklifts no longer need to drive inside the racks.

Narrow Aisle Pallet Racking:

The ultimate goal of narrow aisle pallet racking is to reduce the aisle width in order to increase storage capacity. While other rack varieties require aisles with at least 3 meters in width, this rack type can fit in 2-meter aisles effortlessly.

Narrow aisle racks also provide exceptional adaptability by incorporating height-adjustable beams to accommodate various categories of products. Plus, its price is relatively low, which most warehouses can easily afford.

Automated Storage And Retrieval System (AS/RS):

Let’s meet AS/RS, the ultimate warehouse maestro who effortlessly takes charge of the nitty-gritty: sorting, storing, and fetching your products when you need them most. It’s not just a real-time inventory guru; it’s the wizard of space-saving for your warehouse.

Employing this automated system is like having a team of robots that make sure your inventory is handled with superhero-like accuracy and speed. It also reduces the need for humans to intervene, thus minimizing mistakes and enhancing safety.

Benefits Of Using Racks

Let’s dive into the awesome perks of using racks. These things can seriously make your warehouse life a breeze:

- Saving that floor space: Racks are like the wizards of vertical space. Instead of hogging the floor, they reach for the sky, giving you more room to dance.

- Friendly on the wallet: Racks aren’t breaking the bank. Seriously, they’re the budget-friendly pals of your warehouse. You’ve got a bunch of types to choose from to fit your vibe and budget.

- Ensuring safety: Sturdy and well-installed, racks are your safety heroes. No more dodging risky piles of goods – it’s a safer, smoother dance in the warehouse.

Drawbacks Of Using Racks

Now, for the not-so-fun part, let’s talk about racks’ drawbacks:

- More maintenance needed: To keep the safety vibes high, racks need a bit of love. Regular check-ins, and some maintenance effort – it’s like the dance routine you didn’t sign up for but gotta do to keep things groovy.

- Not one-size-fits-all: Racks are cool, but they can’t store everything. Have delicate or quirky-shaped items? Well, they might need a different spot, like a cozy shelf perhaps.

Defining A Shelf

Distinct from racks, a shelf is crafted for holding products horizontally on a flat surface. It can be freestanding or supported by wall mounts and brackets. Warehouse shelves can be highly customized, with various shapes, sizes, and materials for you to choose from.

Different Shelf Categories

When you’re picking shelves for your warehouse, think about the basics, like how high they go, how sturdy they are, and if they match your products. Now, let’s dive into some awesome options for your warehouse shelves.

Steel Shelving:

Let’s talk about steel shelves, the most common shelving option on the market. Sturdy, easy to put together, high versatility and low maintenance make steel shelving the go-to for warehouse wizards.

The two most popular varieties include the old-school nut-and-bolt type and the modern compression clip type. Both types are built for the big leagues, such as certain workshops and heavy-duty inventory facilities.

Boltless Rivet Shelving:

Boltless rivet shelving is the DIY champ of storage. Crafted from particle board and held together by nifty metal clips or rivets, these shelves are a breeze to assemble. They’re also tough, versatile, and come in various sizes and styles, catering to the unique storage needs of your gig.

This shelf type is perfect for lighter loads and works well with small homes, offices, or warehouses. If you crave maximum flexibility in your inventory space, boltless rivet shelving is your ticket to storage bliss!

Wire Shelving:

Despite not being the Hulk of toughness, wire shelving is definitely the MVP of top-notch visibility. It might not lift heavy loads, but high visibility is what sets it apart from other warehouse shelving.

Having it in your warehouse is like possessing the see-through magic trick for your storage game. Regarding application, wire shelving is perfect for places that need a bit of air and light to protect your goods’ shelf life.

Clipless Shelving:

Never judge a book by its cover, and never underestimate the capability of holding heavy objects of the small-sized clipless shelving. Some models can lift an impressive 300 kg of materials.

As the name suggests, clipless shelving is characterized by the absence of hardware or clips and just comprises particle board and steel bracing. This structure significantly simplifies the assembly process, eliminating the need for specialized equipment.

Bulk Rack Shelving:

Bulk rack shelving is a light-duty member of the warehouse shelf family, despite having the words “rack” and “bulk” in its name. Not only is it boltless (which simplifies the assembly procedure), but this shelf type also offers high durability and flexibility.

This shelving option is ideal for warehouses with limited inventory areas and can handle both light and medium-sized loads. Plus, warehouse staff can access products on this shelf type from all angles, thus reducing the loading and retrieval durations.

Mobile Aisle Shelving:

If you need another option for storage facilities with limited space, give mobile aisle shelving a shot! Mounted on wheels or casters, these shelves are capable of moving from one side to another effortlessly.

You can spot this special shelf type in most offices and libraries, as these places have limited floor areas and require high mobility. Mobile aisle shelving is also customizable, offering a wide range of styles and sizes to meet your diverse storage demands.

Advantages Of Utilizing Shelves

Now that you are accustomed to the top common shelf varieties, let’s dig deeper to know what advantages these storage tools can offer you.

- High versatility: You can customize warehouse shelves in a plethora of ways, from adjusting their heights to changing their materials. They all adapt well to diverse products and various storage scenarios.

- Great for decoration: Since warehouse shelves are available in many styles, they are surely great for decorative purposes. The two most recommended shelf styles are floating shelves and corner shelves.

- Saving floor space: Another brilliant thing about warehouse shelves is that they make good use of your vertical space and can also be affixed to walls. That way, you can free up a huge amount of floor space for other storage purposes.

Disadvantages Of Utilizing Shelves

Similar to racks, warehouse shelves also have their drawbacks. Let’s find out what they are right below:

- Carrying less weight: Shelves are designed to be lightweight storage devices that can only carry light to medium-sized loads. If your products are heavy, consider utilizing the racking system.

- Offering limited storage space: Besides their inability to hold large stuff, warehouse shelves provide very limited space for such items as well.

Comprehensive Comparison Between Shelf VS Rack

With all the understanding provided in the aforementioned parts, the following section will execute a comprehensive comparison between shelf vs rack via nine distinct features. After reading it, you will know what their similarities and differences are.

#1: Floor Space

Racks occupy less of the warehouse’s floor space than shelves.

The rationale lies in the essence of each storage solution. Racks are designed to best utilize the vertical space (by stacking multiple pallets on top of one another) and thus require less floor space.

Shelves, on the other hand, expand horizontally and store items using their many flat boards. Hence, the more products you have, the more floor space you need to install enough shelves to hold them.

#2: Weight Capacity

Shelves offer lower storage capacity than racks.

Why? Well, let’s have a look at their structures again. While racks rely on multiple levels and horizontal bars to hold heavy pallet loads, shelves utilize just a small flat surface to lift a limited amount of goods.

#3: Organizing Ability

Racks offer better-organizing abilities than shelves.

Although both storage devices can contain a variety of products, racks often store identical items in a single unit, making it easier to handle and sort products.

On the other hand, you can place different objects on the same flatboard of a shelf. Despite providing more flexibility, this trait somehow decreases the warehouse shelf’s organizing ability.

#4: Accessibility

It is a bit tricky here with these criteria, but I’m leaning more towards the shelves team. In other words, shelves provide higher accessibility than racks.

The ultimate goal of shelves is to allow warehouse staff easy access for manual handling (picking and retrieving goods). That’s why you don’t get to see high shelves very often.

Regarding racks, their sole purpose is to store heavy items neatly. Having direct access to all items is not a priority. You can clearly see this with the drive-in pallet racking when forklifts are required to travel deep into the rack for goods access.

#5: Durability

In most scenarios, racks are more durable than shelves.

This superior durability is attributed to the metal used to make most warehouse racks. While metal can be corroded, it will take a long time before corrosion actually occurs.

Also, I know that metal shelves do exist. However, shelves are made from other materials as well. One typical material example is wood. Even if well-constructed, wood shelves can’t escape their fate of warping, rotting, or even cracking.

#6: Safety

Both racks and shelves are safe for product storage only if they are correctly installed and used.

Regarding shelves, you should watch out for the items’ weight when loading to avoid collapsing due to overload.

Likewise, racks require proper installation to ensure maximum safety. If not, risky accidents, such as tipping over, may occur and cause huge dangers to both products and human capital.

#7: Customization

Customizations are possible for both shelves and racks, but racks are superior in this criterion.

Of course, you can adjust the shelf’s height. But that is probably everything you can customize on your shelf. Not to mention, the height adjustment here is limited to the shelf’s flat surfaces only.

Conversely, racks provide significantly higher options for customization, such as adding more levels to maximize your warehouse space, or utilizing inclined rails so that pallets can slide to the other side on their own, reducing the need for manual labor.

#8 Environmental Conditions

Racks are less affected by environmental conditions than shelves.

This is likely the easiest conclusion to explain. As mentioned earlier, racks are made of metal and, thus, are more durable and suitable for application in various environments, such as high temperatures or high moisture.

Shelves, on the contrary, are available in many different materials, such as wood and plastic. Clearly, these materials do not perform really well in the aforementioned environmental conditions.

#9: Maintenance Requirements

Both racks and shelves require considerable maintenance efforts to preserve their appearance and optimal function.

Depending on the design and material of these storage devices, you’ll need distinct maintenance measures. For instance, metal racks and shelves demand anti-corrosive treatments, while wood devices need refinishing actions.

#10: Cost

Last but not least, shelves are normally more cost-effective than racks.

The style, size, and material used all have an impact on the price tags of racks and shelves.

However, as racks require more sophisticated technology to render their ability to hold heavy items, they surely cost more. Shelves often come with a simpler design to fit their lower capacity.

Comparison Recap Between Shelf Vs Rack

If all the nitty-gritty details above are a bit overwhelming to you, don’t hesitate to utilize the following recap table for your quick reference:

| Comparison Term | Shelf | Rack |

| #1: Floor Space | Require more | Require less |

| #2: Weight Capacity | Lower | Higher |

| #3: Organizing Ability | Lower | Higher |

| #4: Accessibility | Higher | Lower |

| #5: Durability | Lower | Higher |

| #6: Safety | Require correct installation and use | Require correct installation and use |

| #7: Customization | Lower | Higher |

| #8: Environmental Conditions | Lower | Higher |

| #9: Maintenance Requirements | Depend on material and style | Depend on material and style |

| #10: Cost | Lower | Higher |

Shelf VS Rack: Practical Guidance On Which Option To Choose

When grappling with the decision between shelves and racks for your storage needs, it’s crucial to assess many criteria. Here are some perspectives to look at for an easier decision-making procedure.

- Product weight: If you’re aiming for heavier items, consider racks for your warehouse. However, if you only need to store lighter objects, such as papers or household appliances, then shelves are a better choice.

- Warehouse layout: For warehouses with limited floor areas, you should opt for racks to utilize the vertical space. On the other hand, shelves are more suitable if floor space is not a big issue for you.

- Storage environment: Racks and shelves react differently in different storage environments. Typically, the harsher the environmental conditions, the better it is to use racks for storage.

Summary

In short, the choice between shelf vs rack is all about finding the storage soulmate that vibes with your needs. Shelves, the lightweight yet versatile champs, are perfect for your everyday stuff. Racks, the heavy lifters, tackle the big and bulky items like superheroes swooping in for the rescue.

This article has compared both storage devices against 10 distinct features, to reveal their similarities and differences. Whether it’s the cost-effectiveness of shelves or the customization of racks, each has its moment to shine.

Hopefully, the content herein has provided you with helpful input to make the final choice more effortlessly. Thanks for reading!