China Very Narrow Aisle VNA Pallet Racking System Manufacturer

What Is VNA Pallet Racking

VNA (Very Narrow Aisle) pallet racking is a high-density storage system designed to optimize warehouse space utilization by reducing aisle widths while maximizing vertical storage capacity. It typically utilizes dedicated narrow-aisle forklifts and narrow aisles to access pallets stored at higher heights. VNA racking systems are typically equipped with rail or wire guide systems that allow forklifts to operate in aisles as narrow as 1.6 meters (approximately 5 feet) through the guide system. Ideal for warehouses with limited floor space, the VNA racking system maximizes storage density without compromising individual pallet accessibility.

How does narrow aisle racking work?

Very Narrow Aisle (VNA) racking works by using a narrow-aisle forklift specifically designed to navigate extremely narrow aisles with precision. These narrow-aisle forklifts are guided by a system of wires, guide rails or other navigation aids mounted on the warehouse floor or ceiling. VNA racking systems eliminate the need for wide aisles and can store pallets closer together, greatly increasing storage capacity. The racking systems themselves are designed to fit into narrow aisles while maximizing vertical storage space, often reaching heights of 40 feet or more. This configuration enables the warehouse to store large numbers of pallets while still maintaining access and replenishment of individual items.

Very Narrow Aisle Pallet Racking Design

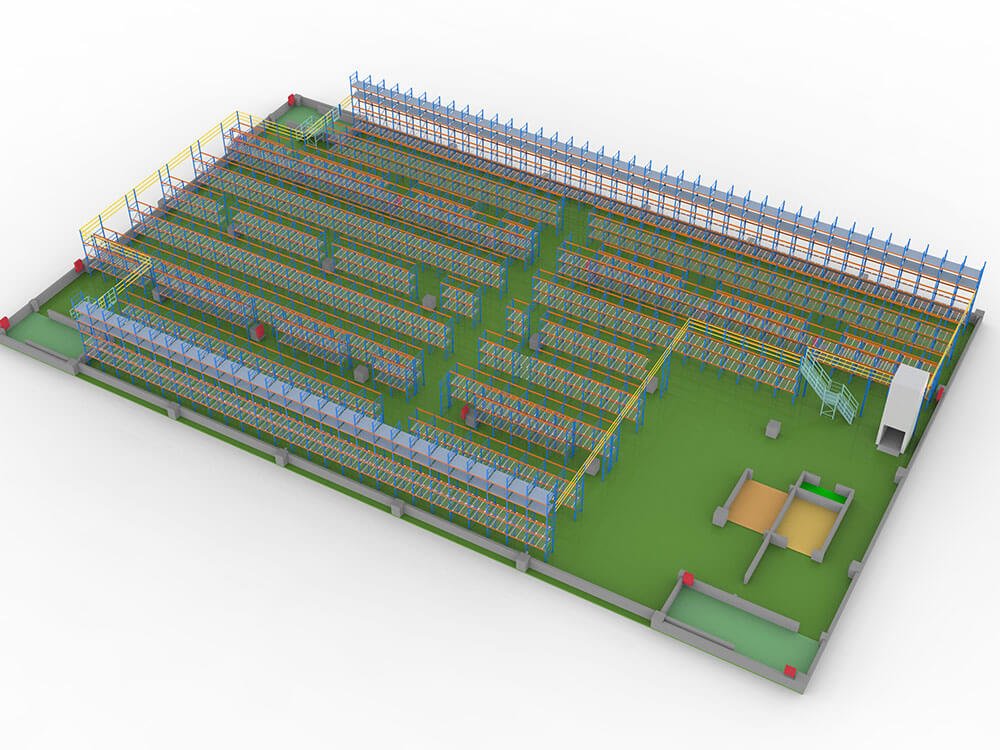

VNA Pallet Racking Layout Design

Please send us detailed data such as warehouse size, cargo size, etc. Our engineers will design a reasonable layout plan for you.

Three-dimensional drawing of VNA Pallet Racking

The exact dimensions of the racks, the load and the number of tiers will be presented to you in a three-dimensional drawing.

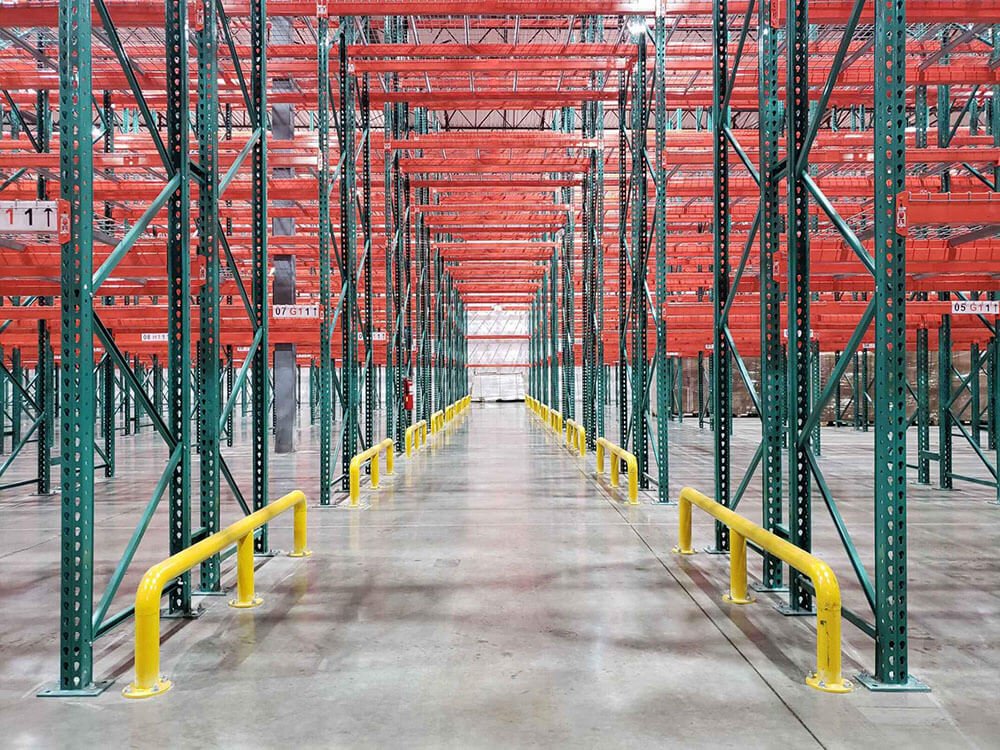

Rendering of VNA Pallet Racking

If the project is complex, we can also produce installation drawings for you, and we can even produce renderings if necessary.

Why Choose Lracking Custom Very Narrow Aisle Pallet Racking

There are several advantages to choosing Lracking for customized Very Narrow Aisle (VNA) pallet racking: First, Lracking has been manufacturing VNA racking for more than 16 years, and has a wealth of experience in the industry, having built a variety of narrow aisle racking projects. Secondly, our VNA pallet racking has passed ISO9001, CE, TUV and AS4084 certifications, so the quality of our products is trustworthy. Moreover, as China is a vast country with a lot of land, Lracking, as a manufacturer of narrow aisle pallet racking in China, usually has a cost advantage over manufacturers in other countries while guaranteeing the quality of pallet racking.

Application of VNA Very Narrow Aisle Pallet Racking

VNA pallet racking for warehouses

VNA shelving is ideal for warehouses that require high-density storage and high SKU (stock keeping unit) turnover. The system improves the efficiency of inventory management, order picking and overall warehouse operations. In addition, VNA pallet racking can be customized to fit specific warehouse layouts, load capacities and product sizes, ensuring the best storage solution for individual needs.

vna pallet racking for high pile storage

VNA (Very Narrow Aisle) pallet racking is the ideal solution for high pile storage in warehouses where space optimization is critical. By utilizing narrow aisles and dedicated forklift, VNA racking allows for dense vertical storage, maximizing the use of available space. The system enables warehouses to store pallets at higher levels while maintaining ease of access for efficient picking and replenishment.

vna pallet racking for high density storage

VNA (Very Narrow Aisle) pallet racking is ideal for high-density storage applications where space optimization is critical. With narrow aisle configurations and dedicated forklifts, VNA racking maximizes vertical storage capacity while maintaining accessibility to individual pallets. The system allows warehouses to store large quantities of goods in a limited footprint, making it ideal for facilities with high storage requirements. In addition, the VNA palletized racking system is designed to accommodate heavy loads, ensuring safe and efficient storage of goods in high-density environments.

Frequently Asked Questions About Very Narrow Aisle Pallet Racking

Do I need a special narrow aisle forklift for narrow aisle racking?

Yes, you typically need a special narrow aisle forklift for Very Narrow Aisle (VNA) racking systems. These forklifts are designed to operate within the narrow aisles and are often equipped with features such as articulating mast and turret heads to maneuver in tight spaces. They may also have guidance systems to ensure precise positioning within the aisle. These specialized forklifts are essential for maximizing storage density and efficiency in VNA racking configurations.

What is the MOQ for VNA Pallet Racking?

For narrow aisle pallet racking, we do not have a minimum order quantity. However, since VNA pallet racking is custom pallet racking and requires a specialized narrow aisle forklift to use. So if you order too few narrow aisle pallet racks the cost will be huge and we don’t recommend you to do so. If you don’t need too much pallet racking, we recommend that you consider selective pallet racking, which has similar functionality and is usually available in lower starting quantities, which will save you money.

What are the advantages of VNA racking system?

Benefits of the Very Narrow Aisle (VNA) racking system include: Increased storage capacity: VNA racking systems have narrower aisles than traditional racking systems, which allows for more efficient use of warehouse space to maximize storage capacity; Increased accessibility: Despite the narrower aisles, the VNA system is designed to allow for easy access to stored pallets. 3. Narrow aisle forklifts can efficiently navigate these aisles to accurately retrieve and store pallets; Enhanced Selectivity: The VNA racking system provides excellent selectivity for quick and direct access to individual pallets. This is especially beneficial for warehouses with high SKU turnover or where specific pallets need to be accessed frequently.

What is the structure of very narrow aisle racking?

The structure of Very Narrow Aisle (VNA) racking typically consists of upright frames, horizontal load beams, and pallet rails or guide rails. The upright frames provide the vertical support for the racking system, while the horizontal load beams support the pallets. Pallet rails or guide rails are installed on the floor within the aisles to guide the specialized narrow aisle forklift. These guide rails ensure precise positioning of the forklifts within the narrow aisles, allowing for safe and efficient operation. Additionally, the racking system may include accessories such as wire mesh decking, row spacers, and aisle end barriers to enhance safety and stability.

What is the difference between narrow aisle racking and selective pallet racking?

Narrow aisle racking and selective pallet racking differ primarily in their aisle width and storage density. Narrow aisle racking is designed for tighter aisles, typically less than 6 feet wide, maximizing storage density by reducing aisle space. It requires specialized forklifts for operation. Selective pallet racking, on the other hand, features wider aisles, allowing for easy access to each pallet. While it offers lower storage density compared to narrow aisle racking, it provides greater flexibility in pallet selection and retrieval.

What is the load capacity of very narrow aisle racking?

The load capacity of narrow aisle racking depends on a variety of factors such as the design of the racking system, the type of forklift used and the size of the pallets stored. In general, narrow aisle racking systems are designed to support heavy loads, typically between 1,000 and 3,000 kilograms per pallet position. However, the exact load capacity should be determined by the actual specifications of each rack. You can consult Lracking for more information on narrow aisle racking load capacity.