The warehouse is one of the most crucial parts of every business; it is where the products are stored, and efficiency plays a vital role. When designing a warehouse, there are so many aspects that must be kept in mind, which help to maximize space, improve efficiency, and be cost-effective.

Hence, your warehouse design plan is very important to be designed carefully, incorporating all the important elements.

If you are looking forward to learning about the important aspects that you should incorporate into your design plan, the guide below can help.

Understanding Warehouse Design Planning

The basic aspect of a warehouse design plan is understanding it carefully and highlighting the key elements that need your attention during the process of designing.

Definition of a Warehouse Design Plan:

A warehouse plan is a strategy that is designed in detail and features the aspects of a warehouse, which are space organization workflow and equipment. The plan ensures that the space is utilized in the best possible way with the efficient movement and handling of products. The physical layout of the warehouse must be compatible with the operational requirements.

An effective design of a warehouse is inclined towards making the best use of space utilization and incorporates safety. The operational costs are also reduced by streamlining the processes, and the handling time is minimized, which uses the equipment and labor.

An effective warehouse design maximizes space utilization, improves workflow, and enhances safety. It helps reduce operational costs by streamlining processes, minimizing handling time, and making efficient use of labor and equipment.

A good design is also adaptable, allowing for future expansion or reconfiguration as business needs change. Additionally, it ensures compliance with safety and building regulations.

Key Elements of a Warehouse Design:

Some of the elements of the warehouse design comprise the following:

- Space utilization in an efficient way is crucial, and it determines the layout of the storage areas and racking systems that are implemented. It also comprises analyzing the space in such a way that clear pathways are present for the workers to commute.

- The layout of the warehouse must be designed with the movement of the goods kept in mind. This comprises keeping an eye on the process of receiving, storing, picking, packing, and then shipping areas. The warehouse, which is well-planned, can help minimize travel time and enhance the flow of operations.

- The right equipment, like conveyor belts and forklifts, is crucial in huge warehouses, and their placement is important to be a part of the warehouse design plan.

- The warehouse design must be efficient enough to enhance the workflow of the warehouse, which improves productivity.

Initial Steps in Creating a Warehouse Design Plan

When creating a warehouse design plan, the initial steps to consider are as follows:

Assessing Warehouse Requirements:

The first stage is assessing the warehouse requirements, which comprises the nature of products, the quantity of products, and whether there are any specialized storage needs. This will help you to create a design that aligns with your requirements.

Setting Clear Objectives:

Keep your objectives clear during the design process of the warehouse plan. When you have in mind goals like enhancing inventory management, optimizing space, and improving operational flow you will be able to create a focused design that supports your objectives.

Understanding Inventory Flow:

You must know the flow of inventory in your warehouse. You have to analyze the way goods move through your warehouse. It is very important to understand the flow of inventory so that the layout of the warehouse can be optimized and unnecessary bottlenecks can be eliminated. It enhances the process of loading the goods, unloading them, and even rotating them for an improved organization.

Factors to Consider in Warehouse Design Planning

The important factors to consider in the process of warehouse design planning are very important to make your warehouse organized, and some of these factors are as follows:

Space Optimization:

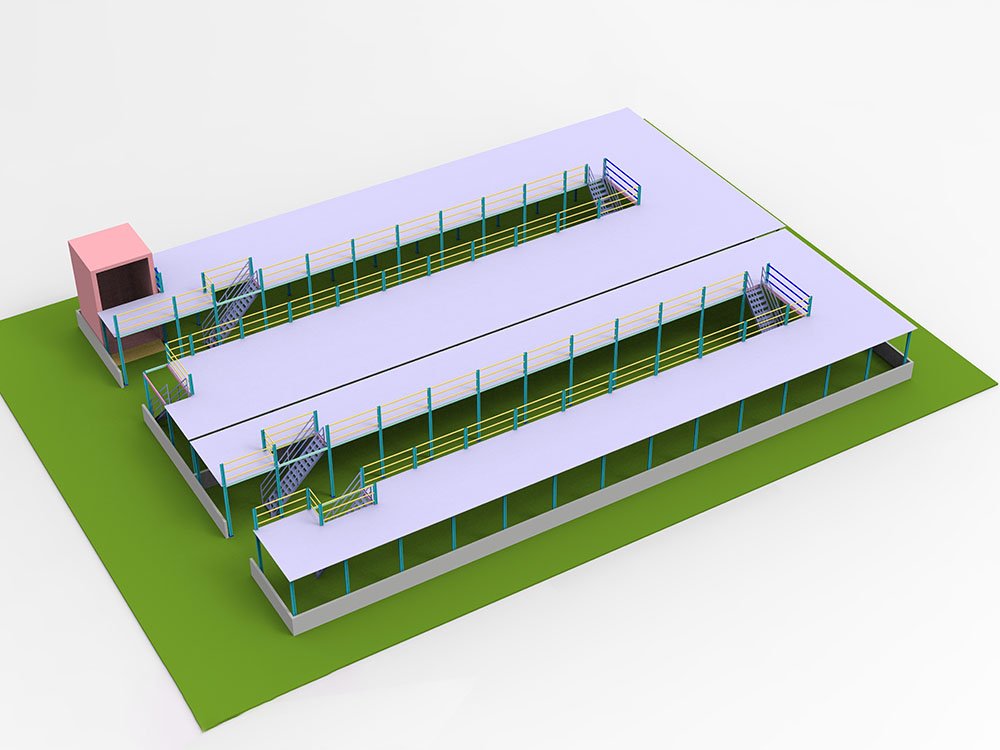

Make the best use of space in your warehouse design. Utilizing horizontal and vertical space is very important for improving the storage capacity of the warehouse. In order to achieve this, you have to make the best use of mezzanines, incorporate adequate racking systems, and ensure that the aisles are wide enough to support the equipment access.

Layout Design Principles:

The simple warehouse design plan will ensure the flow of traffic and easy accessibility. It consists of organizing the storage spaces well and ensuring that the time for each product is minimized. The pathways need to be clean so that workers as well as equipment may reach the products and also ensure safety.

Scalability:

Warehouse design should be created with scalability in mind so that future growth and expansions in the business can be catered to. When a design is scalable, the reconfiguration of the warehouse is easy, and the existing warehouse and its system can easily adapt to the growth. It helps to save money as well as time in the long run.

Types of Warehouse Layouts

There are different warehouse layout types that can be incorporated in a warehouse, each having its own pros and cons.

Linear Flow Layout:

A linear flow layout is suitable for the warehouse, which needs products to move from one end to another. It has a very simple and uninterrupted layout, which is suitable for high-volume operations and the simple handling of inventory.

U-Shaped Layout:

A U-shaped warehouse layout offers improved efficiency in terms of space and also ensures better control over the process of receiving goods and shipping them, in such a layout. The receiving and shipping areas are side by side and create a u-shape design. It reduces the travel distance, and the goods coming in and going out are rotated appropriately.

L-Shaped Layout:

An L-shaped warehouse layout is suitable for warehouses with limited space. It makes use of two sides of the warehouse, where the receiving side is at one corner and shipping on the other. It offers flexibility in the workflow but needs to be designed through very careful planning.

Modern Trends in Warehouse Design Plan

Due to innovations in technology, warehouses are equipped with automated storage systems. Hence, incorporating these trends in the warehouse design plan is crucial.

Integration of Automation and Technology:

Warehouse management systems and structured storage and retrieval systems can help to streamline warehouse operations. These methods help to reduce the human errors and speed up the operations.

Sustainable Design Trends:

As the demand for automated management systems is growing in a warehouse, sustainability is also an important factor. Hence, energy-efficient lighting systems, eco-friendly racking systems, and the incorporation of solar panels is increasing.

Flexible Design Elements:

Flexibility in a warehouse is a key to adapting to the changes that arise in demand. In this case, some flexible racking systems, adjustable shelves, and modular racks are important to warehouse design. These elements help to quickly adapt to the changes that appear as a result of the demands and trends.

Warehouse Design Plan for Space Optimization

The warehouse design plan must be inclined towards space optimization; some of the ways this could be achieved are as follows:

Storage Solutions:

Choose the right storage solution so that the space in the warehouse can be optimized. The pallet racking systems are quite suitable in this case and can store palletized products. Moreover, warehouses that have limited space may also find a warehouse mezzanine to be a suitable choice and give additional storage space.

Zoning the Warehouse:

You can also divide warehouses into different functional zones. You can designate areas for receiving, storage, picking, packing, and shipping. This helps reduce time consumption and enhances the flow of goods.

Vertical Storage Utilization:

Vertical space maximization is a very effective way to help optimize storage capacity, and for this, you can incorporate vna racking systems. It is suitable for such warehouses that have high ceilings, and the accessibility of the products is possible using forklifts and other equipment.

Warehouse Design Plan with Safety in Mind

The warehouse design plan should include safety features so that the workers may move through the warehouse without any issues.

Compliance with Safety Standards:

When designing warehouses, the need to adhere to OSHA guidelines is very important. This consists of ensuring that the racking installation, aisle width, assessment of laid limits, and ventilation are considered. By complying with these regulations, the safety of the workers is enhanced.

Safe Equipment Placement:

Equipment placement should be carried using specific areas where the ladders and forklifts can be stored. The storage space must be easily accessible so that there are no obstacles in between.

Emergency Exits and Signage:

Warehouse design plans must account for energy and signage. The Exit routes should be free from any barriers so that in case of emergency workers can quickly evacuate. Moreover, emergency signage is also very important, followed by first aid kits, fire extinguishers, and exit signs.

Warehouse Design Plan for Improved Workflow

The design plan of the warehouse must consider the aspects which improve the workflow.

Ergonomic Design Considerations:

The ergonomics in the warehouse design improves productivity. The positioning of workstation tasks should be designed in a way that they are easy to reach, and task tables must be adjustable. The concept of design must be focused on ensuring the comfort of the workers.

Streamlined Picking and Packing Processes:

The picking and packing processes should be streamlined and efficient. To minimize the travel time between picking and packing locations, the obstacles from the path must be removed. Also, barcode scanners should be implemented so that the process of packing can be sped up.

Material Handling Efficiency:

Material handling systems like conveyors are implemented so that the process of storage and shipping can become automated. It helps to allow workers to focus more on complex tasks and even enhances the efficiency of the workflow.

Creating a Scalable Warehouse Design Plan

The warehouse design plan must take into consideration future growth and expansion so that later on, the footprint of the warehouse does not need to be expanded. Some of the aspects of creating such a warehouse design plan are as follows:

Designing for Growth:

Designing a warehouse requires keeping growth in mind and ensuring scalability. In this case, you need to plan some added storage, and racking systems must also be such that they can be vertically and horizontally extended. It helps to eliminate the need to opt for costly designs and to spend on future expansion.

Modular Racking Systems:

Modular racking systems are scalable and hence they offer flexibility to incorporate the inventory. The adjustable pallet racking systems and shelves can also be adapted to different sizes of loads. Hence, such systems can be arranged as needed without any renovation requirements.

Adaptable Layouts:

Layouts of the warehouse that offer adaptability can help to accommodate the evolving demands for storage. It helps to increase flexibility in products when the demand rises. It also ensures that the warehouse is capable of meeting the market demands.

Cost-Effective Strategies in Warehouse Design Planning

When creating a warehouse design plan template, cost-effective strategies need to be implemented. Some of these are given below.

Budget-Friendly Storage Solutions:

The shelves and racking systems must be chosen in ways that they offer budget-friendliness. You can also opt for modular racking systems and simple storage methods so that you can have durability and affordability.

Energy Efficiency:

Warehouses are usually huge and are operational day and night hence the cost of electricity is a concern. You can think about implementing energy-efficient lighting solutions and also look forward to incorporating smart climate control systems so that the cost of energy can be reduced. Lights that are operated using motion sensors are also incorporated as an energy-efficient solution.

Lean Warehouse Principles:

The lean principle focuses on minimizing wastage and making the best use of resources. The lean warehouse principles help to streamline the process of inventory and reduce the movement of inventory. It even helps to avoid excess handling, reduce labor costs, and even avoid overstocking.

Common Mistakes to Avoid in Warehouse Design Planning

When designing a warehouse plan template, some mistakes that are commonly made by people and must be avoided are discussed in this section below.

Overlooking Space Requirements:

The assessment of space required for the warehouse operations leads to issues. It is important to analyze the storage space very well so that neither it is underutilized or overcrowded. Inadequate space management may cause severe challenges.

Ignoring Workflow Patterns:

The movement of the products through the warehouse is also considerable. Not keeping this in mind leads to a waste of time and also impacts the flow of goods. It leads to increased travel distance and time, and hence delays occur.

Neglecting Safety Protocols:

Safety protocols, when neglected, may lead to a risky move as they can impact the lives of the workers. Aspects like the proper placement of equipment, and clear walkways are a must for a safe design.

Conclusion

The optimization of the space for a warehouse in an efficient way requires having hands on the right warehouse design plan. If you are looking forward to having an efficient and safe warehouse designed with the right racking systems in place, you can contact us at Lracking. We ensure to make use of our expertise and provide you with a design that enhances the workflow.