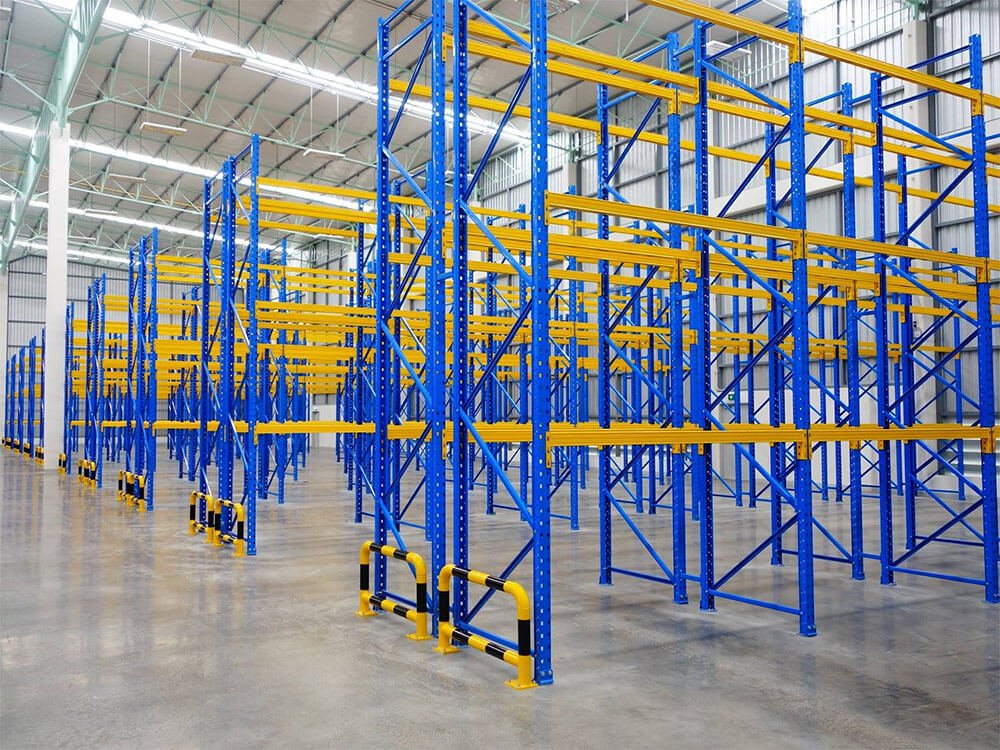

Modern warehouses and industrial storage solutions depend upon metal racking systems. These systems offer a flexible and economical method to organize and store products as effectively as possible, maximizing space and aiding optimal workflow. Though small, for businesses dealing with large inventory, choosing the right metal racking system can significantly boost productivity and storage capacity. Keep reading to find out about metal racking systems and how to choose a good one according to your business needs.

What is Metal Racking?

A structured shelving system for heavy load support and organization in warehouses, manufacturing facilities, and retail stores is called metal racking. Metal racking systems are built with durable materials such as steel or aluminum and are typically constructed to handle wear and tear, making them suitable for heavy duty storage. Metal racking can be categorized as heavy duty metal racking or light duty metal racking for different storage requirements and environmental.

Types of Metal Racking Systems

There are different categories of metal racking systems based on particular storage needs. There is heavy duty metal racking for industrial environment, metal storage racking for general purpose use, metal warehouse racking for high density storage. They offer different benefits for distributing specific inventory needs.

1. Pallet Flow Rack

Pallet flow racks depend on gravity to keep products moving and are best suited to high-volume, fast-moving inventory. Placed on a slight incline, gravity helps to move items along a tidy path toward easy picking, enhancing storage efficiency.

Benefits: For FIFO (first in, first out) inventory, the pallet flow racks are an ideal solution because of their space efficiency and straightforward access.

2. Push Back Rack

Loading from the front into push-back racks allows for quick loading while back-pushing previous pallets to fit new products. For large volumes of the same SKU or similar products, these racks are ideal, as one pallet can occupy the same space as multiple pallets.

Best Use: Great for LIFO (last-in, first-out) inventory systems where the products are not frequently rotated.

3. Selective Pallet Rack

Selective pallet racking is the most versatile and most commonly used system that gives direct access to each pallet. This system is suitable for warehouses where SKUs differ as it prevents moving other products to each pallet.

Benefits: Selective racks have high accessibility and flexibility, which makes them suitable for facilities that hold various inventories.

4. Drive-In/Drive-Thru Rack

Drive-in and drive-thru racks provide the forklift access direct into the racking system to load and unload loads, thereby increasing vertical storage density. They are typically used for uniform goods whose turnover rate is high or frequently rotated.

Advantages: Saves floor space for uniform goods, high-density storage.

5. Cantilever Racking

Cantilever racking is designed to store bulky, long, and irregularly shaped items imcluding pipes, sheets, as well as lumber. It has no front columns, which serve to maximize accessibility and storage efficiency as desired.

Ideal For: Stores where they store large, unwieldy items that require large open storage as well.

6. Double Deep Pallet Racking

Double-deep pallet racking stores pallets two deep, yielding double the storage space compared to standard racks. While it’s easier to retrieve later, it usually requires special equipment.

Benefits: Maximum floor usage with minimal aisle space and high storage density.

7. Adjustable Pallet Racking

You can adjust it in terms of height, depth and width, accommodating multiple sizes and types of loads. This system is easy to adjust as a business grows, making it flexible for changing storage needs.

Best Use: However, it is ideal for businesses that require versatility in storage options.

8. Shelving

For smaller items or bulk products, basic shelving systems are acceptable, as well as allowing for easy access in retail and office settings.

Ideal For: Where easy product access is essential: retail spaces, offices, or warehouses.

9. Multi-Tier Racking

Incorporating multi-tier racking optimizes vertical storage space by stacking different levels, offering high-density storage in limited space. For storing tools, small parts and inventory of various sizes, this system is perfect.

Best Use: Warehouses with plenty of vertical room but little floor space.

10. Longspan Shelving

Larger, heavier items are better suited for longspan shelving which is used for products that don’t fit on traditional shelves. It’s highly durable and can meet warehouse-specific weight demands as well.

Ideal For: Sufficient sturdy support is required for oversized and bulkier items.

11. Wire Shelving

Perishables and delicate items can hang well in wire shelving because it allows for ample ventilation and visibility. The types of areas that typically use this system are the food and healthcare sectors.

Benefits: Its airflow and visibility make it suitable for perishable or sensitive goods.

12. Bulk Rack Shelving

Large open storage areas of bulk rack shelving are ideal for high-volume items that aren’t palletized. As such, this type of shelving is quite commonly employed in warehouses, factories, and distribution centers.

Best Use: Suitable for non-palletised items and loose goods.

13. Rivet Shelving

Rivet shelving has riveted beams for added support and is suited for small—to medium-sized items. Assembling is easy and can be tailored to a range of inventory requirements.

Ideal For: It is used for small warehouses or retail storage needs.

Metal Racking Systems Key Benefits

Space Optimization

You can effectively make use of available space with Metal racking systems. They allow you to store more items in a smaller space, hence maximizing vertical storage. It will enable you to make better use of your floor area by eliminating clutter.

Durability and Strength

Metal racking systems are made of steel and other metals, robust enough to withstand severe use and support heavy loads, which makes them ideal for heavy duty warehouse environments.

Cost-Effectiveness

While theInitial investment for metal racking systems can be high, the durability and low maintenance requirements will result in significant long term savings. These racks are durable and retain their value.

Customization

Metal racking systems can be tailored with adjustable shelving and different load capacities to meet certain specifications. As with any selection, adjustable pallet racking is highly flexible, allowing for future growth and changing storage demands.

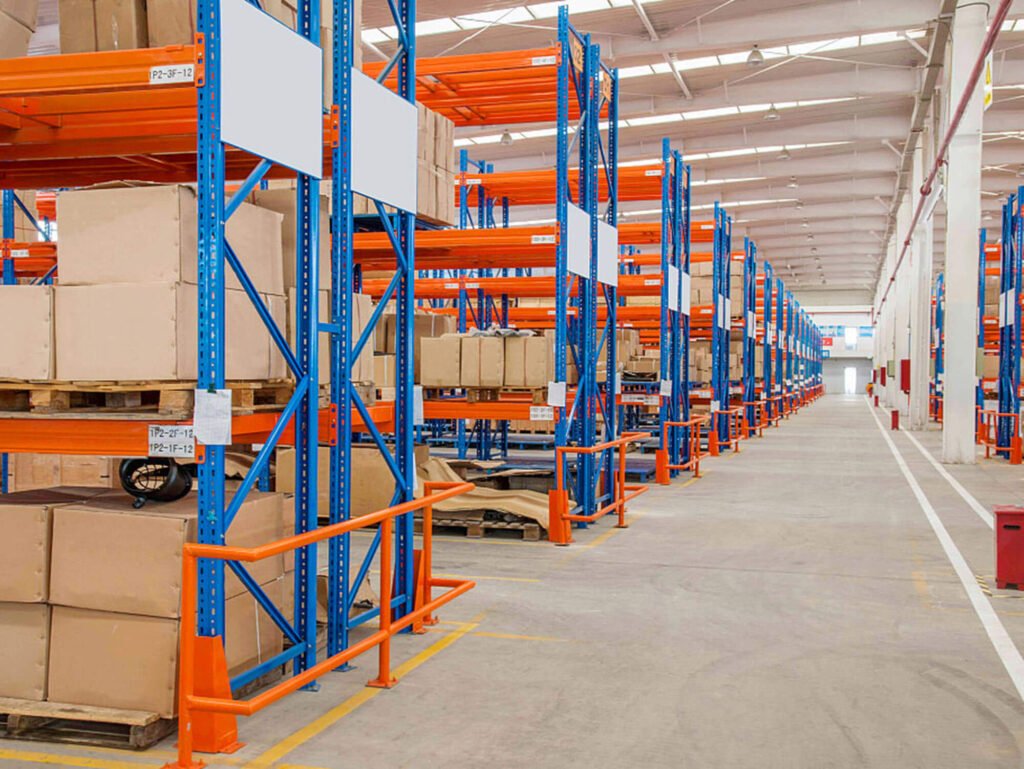

Improved Organization

Metal racking systems provide better access to inventory and easier inventory location and control. They also save time spent searching for products and encourage good workflow, ultimately increasing productivity.

Selecting the Optimal Metal Racking System for Your Business

Load Capacity

It is key to identify the weight limit on each racking type. Make sure to select a metal racking system that will correctly support your storage requirements without compromising security or racking integrity.

Available Space

Calculate your available storage and choose a racking design that maximizes it. Optimal racking setup includes consideration of both horizontal and vertical space.

Type of Goods Stored

The ideal racking system depends on the type of goods—bulk items, fragile products, or irregularly shaped goods. There are racking types suited to different inventory types.

Safety and Compliance

Ensure that your chosen metal warehouse racking meets safety standards and obeys regulations. It will ensure worker safety and prevent compliance issues.

Customization Options

Metal racking systems also provide customization options, including modifying size to fit warehouse layouts. Additional technological improvements, such as RFID tracking, can also contribute to more efficient inventory and monitoring.

Applications of Metal Racking

Warehouses

For large scale storage, metal warehouse racking is necessary in increasing storage density and inventory control. For SKU management in varying SKUs, there are different systems, such as selective or double deep racking.

Manufacturing Facilities

Among other storage systems widely used in manufacturing is heavy-duty metal racking to store raw materials, machinery, and finished products. They function seamlessly, supporting smooth workflow and efficient storage.

Distribution Centers and Retail Stores

Metal storage racking is used in retail and distribution centers to store products for easy organization and convenient access. It makes product retrieval easier and order fulfillment faster.

Other Industries

Metal racking systems are used in a wide array of different industries, spanning from cold storage and automotive industries to libraries and museums. Cold-resistant materials for food storage and adjustable shelves for libraries are some of the required features for each application.

Metal Racking Systems Installation and Maintenance

Installation Process

Proper installation is absolutely critical for stability and structural integrity. To avoid safety risks, consider loading capacities, floor anchoring, and rack alignment.

Maintenance Tips

Ongoing maintenance will prolong the life of metal racking systems. Racks are inspected, cleaned and repaired to keep them in the best possible condition and avoid accidents.

Safety Guidelines

Follow safety guidelines, including proper load distribution and weight limits, and ensure the pack is clearly marked with your contact information. Safety audits and proper loading practices are conducted regularly to ensure safe operation and storage.

Cost Considerations

Advantage: The first investment you incur may be high, but by choosing quality materials and durable structures, the maintenance and longevity of the metal rack systems will be saved in the long run. The price varies with respect to the quality of the material, custom work, and how complicated the installation is. Finding the right type that fits your budget and marks your exact storage needs.

Conclusion

By enhancing warehouse efficiency with metal racking systems, these systems offer robust, adaptable, and space efficient storage solutions for a wide variety of industries. Investing in the right metal racking system designed specifically for your business needs could make a huge difference to productivity, player safety and overall storage space. If you are still contemplating getting such a racking system for your requirements, consider consulting with storage experts who will help you select the system that is perfectly aligned with your storage requirements and operational goals.