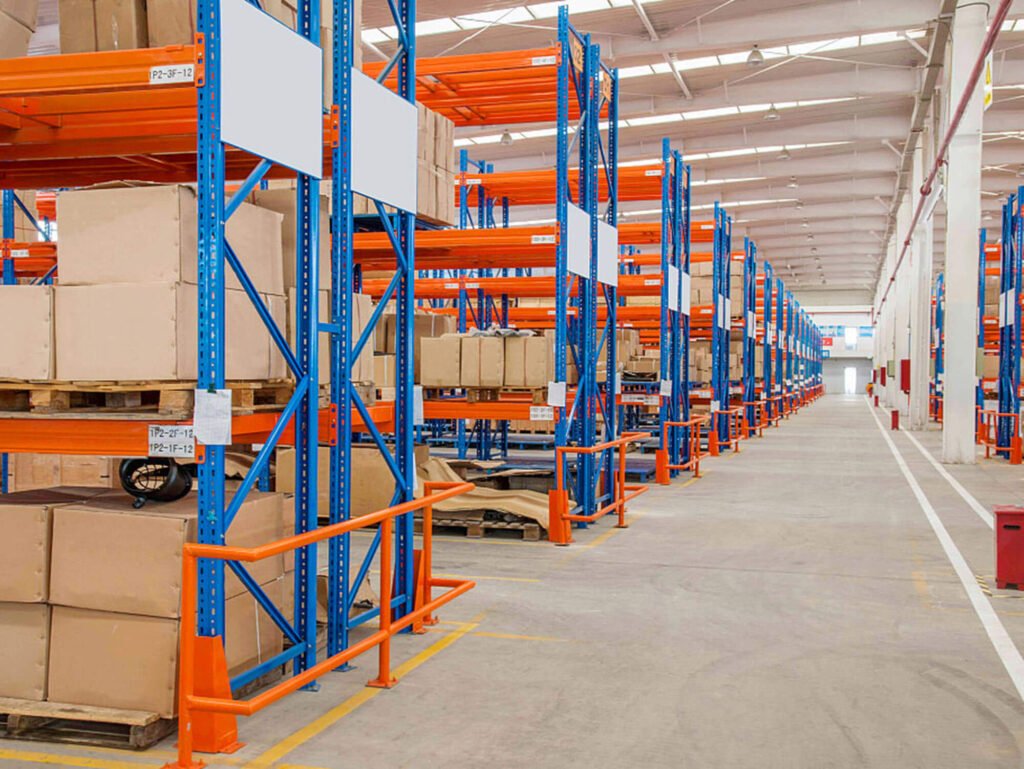

Heavy-duty pallet racking manufacturers are what you need if you have a lot of heavy things in your building, like big machines and bulky tools. They can offer solid solutions designed to withstand the most difficult loads while keeping your warehouse orderly and secure.

But wait, not all racking manufacturers are the same. Choosing the correct one is like choosing a reliable companion for your warehouse adventures. You want someone who understands what they’re doing, does high-quality work, and has your back when it comes to safety and dependability.

In this post, you’ll go over everything you should know about heavy-duty warehouse racking manufacturers. Specifically, this guide looks at what makes them tick, what to look for when selecting one, and even provides insider advice on how to get the most bang for your money.

Choosing A Heavy-Duty Rack Manufacturer: Key Factors

Choosing the correct heavy-duty pallet racking manufacturer is no easy task. You’ll want a brand that is trustworthy, experienced, and can actually do the work. So, to find that reliable manufacturer, it’s vital to consider the following essential factors:

#1: Experience And Expertise

Let’s say you’re employing a chef. You wouldn’t want someone who has just learned how to boil water, right? The desirable choice would be a seasoned professional who knows their way around the kitchen. The same applies to heavy-duty racking manufacturers.

Look for organizations that have been operating for a long time, have a solid track record, and, preferably, specialize in heavy-duty applications. Besides their homepages, where they should display the above information, you should also search for valid testimonials from your connections.

Checking for certificates is another wise decision. Heavy-duty rack manufacturers accredited by respected organizations, such as the Rack Manufacturers Institute (RMI) or the Fédération Européenne de la Manutention (FEM), should be reliable, as these certificates demonstrate that they adhere to high quality and safety requirements.

#2: Design And Engineering Capabilities

Imagine attempting to construct a Lego castle without instructions. It’d be a disaster, right? That’s why design and engineering capabilities are so important when selecting a heavy-duty warehouse racking provider.

They should have bespoke design choices, such as the ability to make racks that are exactly the size and shape of your warehouse. They should also be able to work with complicated layouts, such as multi-level systems or small aisles.

And never forget about safety! A reputable manufacturer will do extensive structural studies and calculations to guarantee that their racks can bear the most extreme loads and comply with all safety laws.

#3: Manufacturing Processes And Quality Control

Have you ever purchased a piece of furniture and it came apart after a few months? Isn’t it frustrating? Hence, it’s critical to choose a pallet racking company that employs high-quality materials and production procedures.

Inquire about the steels they use, their welding procedures, and how they finish the racking structures. You’d want a manufacturer that utilizes high-quality steel, employs expert welders, and has stringent quality control methods in place.

They should also adhere to rigorous quality standards by having certain certifications below:

- Certifications related to heavy-duty racking: This category includes three main standards, which are EN ISO 3834-2 (ensuring precise and consistent welding for sturdy racking structures), EN 1090-1 (guaranteeing the racks meet European steel construction safety standards), and EN 13501-1 (A2-s1, d0) (validating the racking paint contains no lead and does not spread fires).

- Certifications related to heavy-duty rack manufacturers: Beyond product-specific certifications, the manufacturers themselves should qualify for the following standards: ISO 9001 (indicating their dedication to customer satisfaction and continuous improvement), ISO 45001 (showing their adherence to occupational health and safety management systems), and ISO 14001 (highlighting their commitment to environmental management).

#4: Reputation And Customer Service

Word of mouth may be an effective tactic, particularly for large purchases such as warehouse racking. As mentioned earlier in the #1 factor, ask around in your sector to see who other warehouse managers would suggest. You can also read online reviews and testimonials to get a sense of a manufacturer’s reputation.

Besides reputation, customer service is important too! Take note of how attentive a manufacturer is to your queries. A trustworthy producer will give excellent customer care throughout the purchasing process, from the first consultation to post-sales assistance.

#5: Lead Times And Delivery

Time is money in business; thus, lead times and delivery are crucial factors to consider when selecting a pallet racking company. How long will it take to design, produce, and deliver your racks? Can the manufacturer satisfy your project’s timelines?

Make sure to ask about their delivery options and charges as well. Do they provide worldwide shipping? Can they manage the customs and import regulations? Having your racks delivered on schedule and in excellent shape is important to keeping your warehouse operations running smoothly.

Cost Considerations For Heavy-Duty Pallet Racking

Let’s address the elephant in the room: expense! While heavy-duty warehouse racking is required for successful warehouse operations, it’s crucial to understand the cost implications. This will allow you to make more informed selections and strike the ideal balance between cost and quality.

Decoding The Factors That Influence Cost

Several variables influence the total cost of heavy-duty racking. First and foremost, the materials utilized have an important impact. High-strength steel is obviously more durable than normal steel, though it costs more.

Additionally, the design intricacy and any adjustments necessary will influence the pricing. For example, adding features like seismic reinforcement or specialty coatings will raise the expenditure.

Labor expenses related to production and installation are another consideration. Reputable manufacturers with competent labor teams may cost more, but they provide more certainty of quality and knowledge.

Finally, always factor in transportation prices, as these figures vary according to the distance between the manufacturer and your warehouse, as well as the size and weight of the racking system.

Finding The Right Balance Between Cost And Quality

While it’s tempting to opt for the lowest price, remember that quality and safety should never be sacrificed when it comes to heavy-duty pallet racking. Investing in high-quality structures from a trusted manufacturer improves the lifespan and reliability of your system, eventually saving you money on repairs and replacements in the future.

Low-cost pallet racking might result in hidden expenses in the long run. Poor materials and construction lead to repeated failures, thus demanding costly repairs or perhaps total replacement.

Furthermore, inferior racking systems pose safety risks, which might result in accidents, injuries, or inventory damage. The most dangerous part is that these expenses can rapidly accumulate, turning the original “bargain” into your worst regret.

Exploring Cost-Effective Options

How then can you acquire premium heavy-duty warehouse racking without breaking the bank? You might make your investment more reasonably priced via the following ways:

- Negotiating with manufacturers: Don’t be afraid to discuss pricing and conditions with prospective suppliers. Many manufacturers are eager to provide discounts, particularly for large purchases or returning clients.

- Buying in bulk: If you have a big warehouse or plan to expand, acquiring more racks can typically lead to considerable cost savings.

- Considering used or reconditioned racks: For companies with limited budgets, used or refurbished racking is an affordable choice. But before purchasing, carefully assess the safety and condition of the racks.

Benefits Of Choosing A Chinese Heavy-Duty Rack Manufacturer

China has emerged as a worldwide industry leader when it comes to heavy-duty warehouse racking. Chinese heavy-duty rack manufacturers provide an appealing mix of cost savings, producing experience, and rising quality standards. Let’s consider the specific benefits of choosing a Chinese supplier for your needs with warehouse racking.

Cost Advantage

One of the most important benefits of sourcing heavy-duty racking from China is the considerable cost reductions. China’s low labor costs and economies of scale result in more competitive pricing than manufacturers in other nations.

Plus, their established supply chains, efficient manufacturing methods, and availability of a diverse variety of raw materials all contribute to Chinese racking systems’ affordable cost. This is ideal for companies trying to optimize their budget without compromising on quality.

Manufacturing Expertise

With decades of expertise in heavy-duty racking, Chinese racking manufacturers have polished their abilities and know-how, inventing efficient production methods and leveraging cutting-edge technology to make high-quality racking systems.

The sheer magnitude of China’s manufacturing industry results in a huge production capacity, enabling enterprises to meet even the most stringent order quantities and deadlines.

This is especially beneficial for firms with big warehouses or those experiencing quick expansion, since Chinese manufacturers can easily adjust output to suit changing demands.

Quality And Certifications

While quality issues have always been associated with Chinese items, the environment has changed considerably in recent years. Prominent Chinese heavy-duty rack manufacturers now adhere to strict quality control processes and have international certifications such as ISO 9001, FEM, and RMI.

These certifications exhibit a commitment to quality management, product safety, and international standards. By choosing a well-known Chinese manufacturer, you can ensure the quality and durability of your pallet racking system.

Customization Option

Chinese heavy-duty rack manufacturers are noted for their adaptability and readiness to accept unique designs. That’s an immense benefit for organizations that require specialized storage or warehouse configurations.

Whether you want a racking system with non-standard dimensions, particular load capabilities, or special features like seismic reinforcement, Chinese manufacturers can satisfy all your requirements precisely. This degree of customization guarantees that your racking system fits exactly into your warehouse and maximizes storage space.

Overcoming Challenges

While sourcing from China has many benefits, be aware of possible issues and take proactive steps to address them. Language and cultural differences may be challenges at times, but you can resolve them by communicating clearly, building strong relationships, and, if required, using translation services.

Maintaining quality control is also really crucial. To ensure product quality and compliance with safety regulations, carefully look at potential suppliers, get samples, and conduct inspections.

Working With A Heavy-Duty Pallet Rack Manufacturer

Working with a heavy-duty pallet rack manufacturer is a collaborative process that involves more than just acquiring a product. This part outlines vital phases you should conduct for a smooth partnership.

Consultation And Design

The first step in working with a manufacturer is a detailed consultation to determine your warehouse’s specific needs. This phase is typically about providing your warehouse layout (dimensions, ceiling height, and other impediments), as well as information about the items you keep, their size, weight, and any special handling requirements.

After having these insights, the manufacturer’s design team will collaborate with you to draft a unique racking design that optimizes storage capacity while conforming to safety rules and industry standards. They’ll consider aisle width, beam spacing, and upright height to promote efficient product flow.

3D modeling tools are often used during the design stage to show how the racking structures fit and run in your inventory facility. This approach seeks to guarantee that the resultant design will satisfy your requirements.

Installation And Implementation

Once the design is complete, the manufacturer will supervise the installation. A team of skilled installers will erect and secure the racking system in accordance with the confirmed design. Proper installation is vital for the racking system’s safety and lifespan, since faults or oversights can jeopardize its structural integrity and cause accidents.

After installation, the manufacturer should train your warehouse workers on how to use the racking system safely and efficiently. Some key topics include correct loading and unloading techniques, weight capacity restrictions, and regular inspection and maintenance duties.

In addition, the manufacturer should provide continuous support and maintenance to guarantee that your racking system continues to function well. This last step may involve regular inspections, repairs, or modifications as required. You’ll get to know more about this step in the next part.

Lracking: A Reliable Chinese Manufacturer Of Heavy-Duty Racking

With a strong reputation and more than 16 years of industry expertise, Lracking has become a top brand in the field of heavy-duty pallet racking producers. But how does this Chinese producer distinguish itself from the rivals? Let’s investigate the elements that appeal to companies looking for robust and quick racking solutions.

Extensive Product Range And Customization

Lracking provides a comprehensive range of heavy-duty racking solutions, including pallet racking, mezzanine flooring, and cantilever racking, to meet the different storage demands of numerous sectors.

The Chinese manufacturer understands that every warehouse has various needs, hence their capacity to provide tailored racking systems ensures that your storage solution is fit for your particular need.

Whether you want conventional configurations or custom designs, Lracking’s skilled engineers and designers can work with you to construct a racking system that maximizes warehouse space and throughput.

Quality Assurance And International Certifications

Lracking not only provides a diverse choice of heavy-duty racking solutions, but it also prioritizes quality by adhering to tight manufacturing standards and employing high-quality materials.

Their products have received the ISO 9001:2015 and AS 4084:2012 certifications, as well as being certified by TÜV Rheinland as a verified supplier. These achievements display their dedication to safety and conformity with international standards, reassuring clients that Lracking’s storage systems are long-lasting, safe, and secure.

Cost-Effectiveness And Value

Heavy-duty pallet racking from China might be an affordable option for firms looking to optimize their budget. Lracking’s established supply networks and efficient manufacturing methods allow it to provide more affordable price ranges when compared to other manufacturers in other nations.

Plus, their ability to deliver tailored solutions at reasonable expenses makes them an appealing choice for organizations of all sizes.

Commitment To Customer Service

Apart from the above mentioned factors, Lracking enjoys its customer-centric approach and offers complete help throughout the purchase process. Their will to create long-term bonds with clients helps define them as a consistent and reliable friend.

From initial consultation and design to installation and after-sales support, their team of specialists is always committed to your pleasure.

Innovation And Sustainability

Last but not least, Lracking values innovation, continuously investigating new technologies and materials to improve their heavy-duty racking. They try to provide cutting-edge racking solutions that boost warehouse productivity, safety, and sustainability.

This dedication to research and development ensures that Lracking’s products remain at the forefront of the industry, meeting the changing needs of modern warehouses.

Conclusion

Not only is it hard to pick the right heavy-duty pallet racking manufacturers, but that choice can make or break how safe and efficient your facility is. Remember that it’s not enough to just find the best choice. You need to find a partner who can give you a safe, reliable, and high-quality racking system.

That explains why you should do your research, ask the correct questions, and prioritize quality above money. Consider factors like character, knowledge, creative abilities, manufacturing processes, and lead times. Don’t be hesitant to seek assistance if necessary, and always prioritize safety and compliance with industry standards.Bear in mind that it is a prudent decision to invest in a heavy-duty pallet racking system that is both durable and long-lasting for the future of your warehouse. These principles are prioritized by Lracking, a reputable and dependable Chinese company that offers heavy-duty pallet racking options. Thanks for reading!