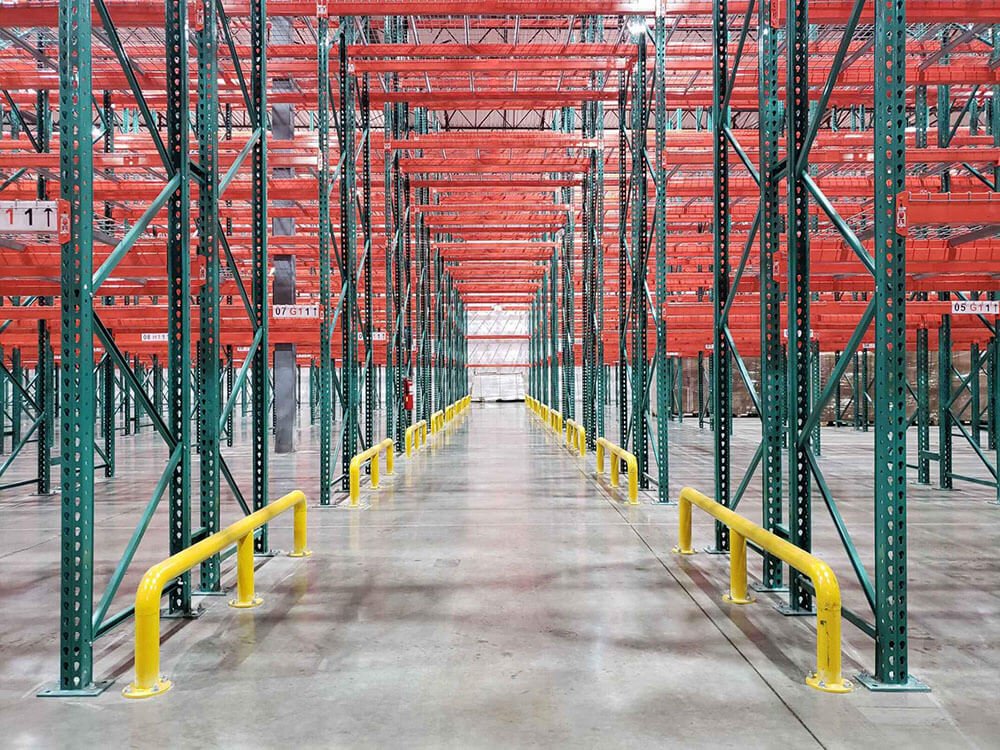

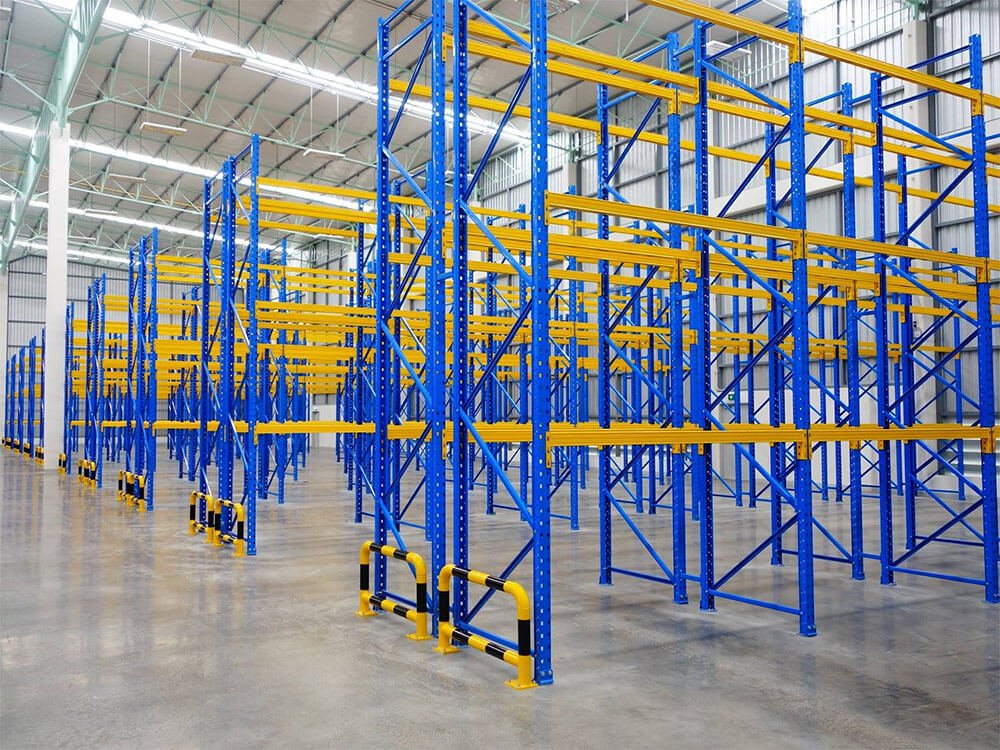

china heavy duty industrial pallet racks for storage for sale

What Is industrial pallet racking?

Industrial pallet racking refers to a storage system designed to store palletized materials in warehouses and distribution centers. It consists of upright frames, horizontal beams, and wire mesh decking or pallet supports. This system allows for efficient use of vertical space while providing easy access to stored goods using forklifts or other material handling equipment. Industrial pallet racking comes in various configurations, such as selective pallet racking, drive-in racking, radio shuttle racking, push-back racking, and pallet flow racking, etc, catering to different storage needs and space constraints in industrial environments.

Features of customized industrial pallet racking

Customized industrial pallet racking offers several features tailored to specific storage requirements:

1. Flexible Design: Customization allows for the design of pallet racking systems that precisely fit the available space and accommodate the unique characteristics of the stored items.

2. Height and Width Adjustability: The height and width of the racking can be adjusted to maximize vertical storage space and accommodate varying pallet sizes.

3. Load Capacity Optimization: Custom designs ensure that the racking system can safely support the intended load capacities, considering factors like pallet weight, dimensions, and load distribution.

4. Material and Finish Options: Clients can choose from different materials, such as steel or aluminum, and finishes like powder coating or galvanization, depending on their durability and environmental requirements.

5. Accessories Integration: Customized solutions can incorporate accessories like pallet supports, wire mesh decking, column protectors, and safety features to enhance functionality and safety within the warehouse.

6. Compliance and Safety Standards: The design can adhere to industry standards and regulations to ensure safe operation and compliance with local codes and regulations.

7. Scalability and Expansion: Custom pallet racking systems are designed with scalability in mind, allowing for future expansion or reconfiguration as storage needs evolve over time.

Industrial Pallet Racking Design

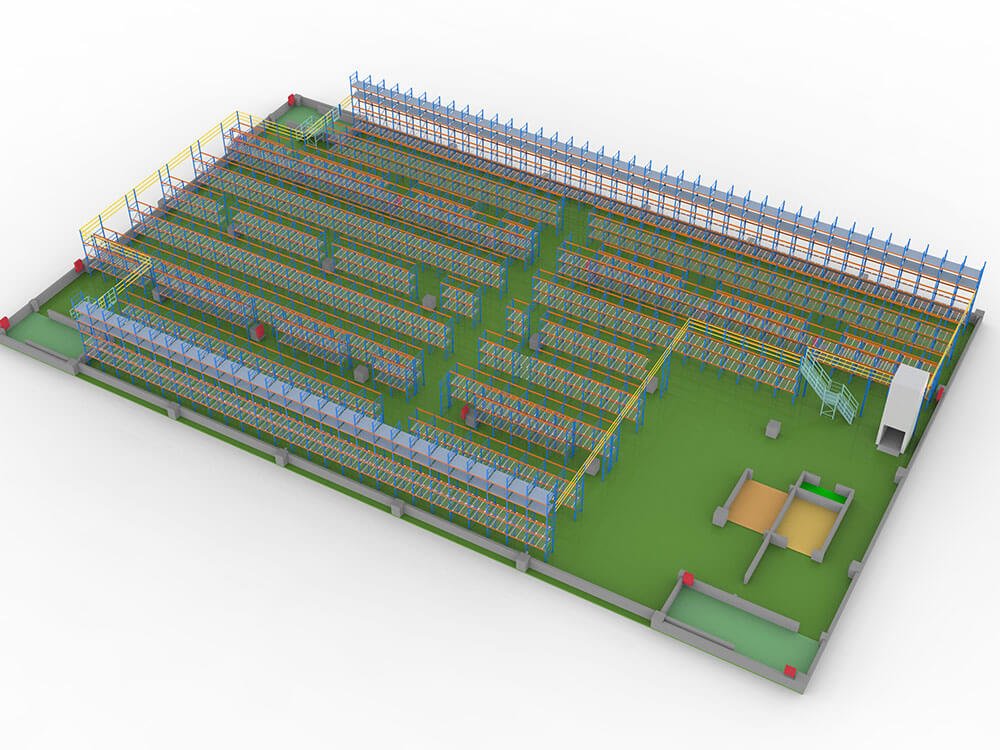

Industrial Pallet Racking Layout Design

Please send us detailed data such as warehouse size, cargo size, etc. Our engineers will design a reasonable layout plan for you.

Three-dimensional drawing of industrial pallet racking

The exact dimensions of the racks, the load and the number of tiers will be presented to you in a three-dimensional drawing.

Rendering of Industrial Pallet Racking

If the project is complex, we can also produce installation drawings for you, and we can even produce renderings if necessary.

Why Choose Lracking Custom Industrial Pallet Racking

There are several benefits of choosing Lracking for customized industrial pallet racking:

1. Expertise and experience: As a top pallet racking manufacturer in China, Lracking has nearly two decades of experience designing and manufacturing customized pallet racking solutions for specific warehouse requirements.

2. Customization Options: Lracking offers a wide range of customization options including sizes, load capacities, and pallet racking accessories to ensure that the pallet racking system perfectly fits the needs of your warehouse facility.

3. Quality Assurance: Lracking’s strict adherence to quality control measures and industry standards, as well as our professional certifications such as ISO9001, CE, TUV, and AS4084, ensures that your customized pallet racking system will be durable, reliable, and long-lasting.

4. Cost Advantage: China is a large manufacturing country with abundant labor resources. Sourcing industrial pallet racking from China has obvious cost advantages while ensuring quality.

5. Full Support: From initial drawing design to racking installation and post-sales support, Lracking provides full assistance throughout the process to ensure a smooth and successful implementation of a custom pallet racking solution.

6. Safety and Compliance: Lracking makes safety a top priority when designing palletized racking systems, ensuring compliance with relevant safety standards and regulations to create a safe working environment within the warehouse.

Application of Industrial Pallet Racking

Industrial rack for Warehousing and Distribution Centers

In large-scale warehousing and distribution operations, industrial pallet racking maximizes vertical space utilization, enabling high-density storage of goods. This facilitates streamlined inventory management and order fulfillment processes, improving overall operational efficiency.

Industrial Pallet Racks For Cold Storage Facilities

Industrial pallet racking is suitable for cold storage environments, such as refrigerated warehouses and food processing facilities. Its sturdy construction and compatibility with temperature-controlled settings enable the safe and organized storage of perishable goods while maximizing space utilization.

Industrial Pallet Racks For Manufacturing Facilities

Industrial pallet racking is extensively used in manufacturing plants to store raw materials, work-in-progress inventory, and finished goods. The ability to customize rack configurations allows for efficient organization and easy access to materials needed for production processes.

Frequently Asked Questions About Industrial Pallet Racking

What are the types of industrial pallet racking?

There are several types of industrial pallet racking, each designed to meet different storage needs and warehouse layouts. Some common types include: selective pallet racking, drive-in pallet racking, push-back pallet racking, pallet flow racking, double-deep pallet racking, narrow aisle pallet racking, shuttle pallet racking, gravity pallet racking, mobile pallet racking, and ASRS, to name a few.

How long is the warranty on industrial pallet racking?

Industrial pallet racking generally belongs to heavy-duty pallet racking, so the materials used are very thick, and they are not easily damaged under normal circumstances. To ensure your peace of mind in purchasing, we provide a five-year warranty service for industrial racks under non-human-induced damage situations.

What is the load capacity of industrial pallet racking?

The load capacity of industrial pallet racking varies depending on a number of factors, including the type of racking system, the size of the beams and uprights, and the quality of the steel. In general, standard selective pallet racking systems typically have load capacities between 1000 and 3000 kg. However, depending on the type of racking system (e.g. selective, drive-in, double-deep, narrow aisle racking), the spacing of the beams and the type of pallets to be stored, the load capacity can vary considerably. It is important to consult with the manufacturer of your pallet racking system to determine the specific load capacity for your application.

How much does industrial pallet racking cost?

The cost of industrial palletized racking can vary greatly depending on several factors, including the type of racking system, size, load capacity, quality of materials, and accessories required. As a rough estimate, selective pallet racking systems typically cost between $30 and $50 per pallet position, while more specialized racking systems such as drive-in or shuttle racking can cost between $50 and $200 per pallet position. These are general estimates, however, and it’s best to consult with the racking manufacturer to get an accurate price for your specific needs.

How long does it take to customize industrial pallet rack?

The time it takes to customize an industrial pallet rack can vary depending on a variety of factors, including the complexity of the design, the size of the project, and more. Generally speaking, it usually takes 15-20 days to customize the industrial racks required for a 500-square-meter industrial warehouse. For more accurate times, please communicate directly with the industrial racking manufacturer.

Can industrial racking be integrated with warehouse management software?

Yes, industrial racking systems can be integrated with warehouse management software (WMS) to optimize inventory control, order processing, and overall warehouse efficiency. By connecting industrial racking with WMS, businesses can track inventory levels in real-time, automate inventory replenishment, manage picking and packing processes more efficiently, and improve overall warehouse organization. This integration enhances inventory accuracy, reduces errors, and streamlines warehouse operations for better productivity and customer satisfaction.