Pallet racking cost is always a primary consideration for budget-conscious warehouse managers and administrators. When researching the expense of pallet racking, it is virtually impossible to find an exhaustive answer right away.

In reality, there are numerous cost-influencing variables in the realm of pallet racking and storage applications, including the rack’s capacity, dimensions, material, racking type, and the new-or-used pallet racks.

Clearly, estimating pallet racking costs is a daunting task. So, if you’re having such difficulty, you can refer to the content herein. This article aims to provide price ranges for certain pallet racking types and explain why this investment can help consumers like you enhance warehouse performance in the long run.

Key Questions You Must Answer Before Thinking About Pallet Racking Cost

Before thinking about pallet racking expenses and making an investment in this type of asset, you need to ask yourself a handful of questions. Otherwise, all later considerations and estimations will become worthless. Here are the key questions:

- What are your storage demands? – It is imperative to establish a clear understanding of your storage demands. Think about the measurements and characteristics of the items you will stock. These inputs will reveal your ideal pallet racks and further inventory requirements (such as cold storage or stocking of hazardous materials).

- Do you need any specific additional components? – Wire mesh, safety barriers, and column protectors are a few of the pallet racking accessories that you can employ to personalize your pallet racks. Although they may increase your overall pallet racking cost, these additions are great sidekicks for certain pallet systems and can improve warehouse safety.

- What is your available budget for pallet racks? – Designating a specific budget in advance is crucial. This practice helps map out all the viable pallet racking types available to you. Doing this also facilitates healthy financial health for your business, as you are less likely to go over budget with your choices.

Understanding Various Factors Influencing Pallet Racking Cost

Although the pallet racking cost appears straightforward at first glance, it is actually influenced by a number of factors. Besides self-evident elements like pallet racking’s height and weight capacity, there are other factors that may surprise you. Here is a detailed cost breakdown analysis for pallet racking.

Pallet Racking’s Weight Capacity

Pallet racking is designed to store a specific weight range of materials and products. Going beyond that upper limit is not only unwise but also a guarantee for disasters. Fortunately, that vital information is displayed on each pallet rack, specifying its maximum weight and allowable beam elevations.

When choosing a suitable pallet racking system for warehouses, weight capacity is often the most crucial consideration, which is contingent upon your stored product’s characteristics. A general rule is that racking systems supporting greater weight capacities are often made from expensive materials and thus bear a higher cost.

Pallet Racking’s Height

How high your storage system goes is another critical factor that determines the pallet racking cost. This dimension is often limited by a few elements, such as the warehouse’s height, fire safety regulations, forklift reach, and the rack structure itself.

Although maximizing product storage height can significantly improve vertical space utilization, it also entails increased expenses and more stringent regulations.

For instance, if you intend to store items that exceed 3.5 meters (or 12 feet) in height, you’re venturing into the realm of high piled storage. This causes your local authority to increase its scrutiny during the permitting process, with a particular focus on safety concerns.

In addition, you must ensure that the additional product weight will not overload your uprights. To do that, you’ll need to invest in more supporting accessories. In brief, the price of pallet racking systems increases proportionally with their height.

Pallet Racking Types

There are numerous pallet racking options available on today’s market. In addition to the standard selective racks, which are utilized in most warehouses, you can find a wide variety of other racking systems that meet your inventory needs. And you should expect to find varying prices for different pallet racking types.

Selective pallet racks are properly the most popular and economical option out there. Besides, you can consider pallet flow, drive-in racks, and even the costly pushback options. Each design has its own pros and cons and can cater to your distinct storage demands.

So, when thinking of which pallet racking systems to use, cost consideration is important, but assessing the long-term benefits that a specific racking option can offer to your storage facility is also critical.

Pallet Racking Quality

Let’s say you want to employ selective pallet racks in your warehouse. You go online, search for their price, and are surprised that this information varies from one supplier to another. Why is it? Well, the answer lies in differences in pallet racking quality.

When designing a storage rack system for customers, manufacturers must take into account many factors, including their actual storage demands and the warehouse’s conditions. These inputs will determine the required quality of the pallet racking, such as what material it should be made from to achieve customers’ desired weight capacity.

Moreover, each rack company has its own manufacturing method and technological expertise. So, choosing more professional partners requires a larger budget due to the higher-quality racks they produce.

Pallet Racking Quantity

Your pallet racking budget is also influenced by the dimensions and configurations of your warehouse, which ultimately determine the number of racks you need. Therefore, it is essential to evaluate the arrangement and available space of your storage facility before thinking of the pallet racking cost.

As pallet racks are offered in sections, let’s take into account the number of sections required for every aisle. There are numerous rack systems commercially available, so consider carefully the number you need that will meet your storage demands and budget.

While high-quality pallet racking costs you more money, a large quantity of racks (if your warehouse permits) may help you receive volume discounts from suppliers or manufacturers.

Pallet Racking’s Status: New Or Used

In most cases, the cost of used pallet racking is going to be less than the cost of new pallet racking. If you’re on a tight budget and don’t care much about aesthetics, second-hand pallet racks are a good choice since they offer relatively equivalent quality compared to new racks but can save you lots of money.

However, there are reasons why people still trust new pallet racking for their warehouses. Utilizing used racks comes with a few risks, such as no warranty, hidden damages from previous uses, and difficulty scaling up your facility as their designs are often obsolete and incompatible with modern racks.

Briefly speaking, the selection between new or used pallet racking is really a budget issue. While the former provides various benefits, from quality to warranty, it surely costs more than the latter.

Pallet Racking’s Markets

The market, the most ever-changing factor, is next on our list of factors influencing the pallet racking cost. The market here means the supply and demand for a particular product at a point in time. When demand is high, prices go up. This rule applies to all items, and pallet racking is no exception.

Therefore, it is necessary to look at the purchase timing when budgeting your pallet racking cost. For example, if you buy pallet racks when the price of steel on the market is rising, you will need more money for the investment as steel is one of the main materials in these storage solutions.

Other Factors

Now that you’ve gone over the major factors, let’s explore a few other variables that can affect the cost of your pallet racking. The following list can give you a more all-rounded picture of how pallet racking costs vary.

- Permit applications: You will need a permit in certain situations, such as high-pile storage mentioned above. Therefore, permit applications should be on your budgeting list, as there will be fees. Permitting fees and approval times might vary drastically depending on your location.

- Building codes and local regulations: When choosing pallet racking systems, don’t forget to consider building codes and local regulations, especially fire safety stipulations. These rules will require certain modifications to your racks’ design, such as allowing enough room for egress routes, and thus increase the overall cost.

- Installation difficulty: The cost and effort needed to complete pallet racking installation are directly proportional to its difficulty. Of course, more time and more people are required to put many large racks to work. Conversely, installing a few small-sized pieces is easier and faster.

- Warehouse floor specifications: To utilize certain racking systems, especially heavy-duty racking, you will need to upgrade your warehouse floor. Make sure the floor is robust enough to withstand the weight of the fully-loaded racking system above. This upgrade can indirectly contribute to your total pallet racking cost.

- Seismic testing: This is often mandated by municipal laws if you are installing pallet racking in seismically active areas. Maintaining the racks’ quality service in these locations requires the compliance of many regulations and thus may significantly increase the cost of design and installation.

- Additional services from manufacturers: If you choose to use additional services, such as pre-sales, after-sales, or maintenance services, expect that the total pallet racking price will rise. Although they cost a bit more, these services are indeed necessary to safeguard your equipment and ensure its functionality.

Cost Estimations Of Popular Pallet Racking Types (How Much Does Pallet Racking Cost)

So far, this article has covered all the basic variables that help shape your pallet racking cost. Now, in the upcoming part, you will get to know the price ranges of the top pallet racking types. However, please take these costs with a grain of salt, as they are just estimations.

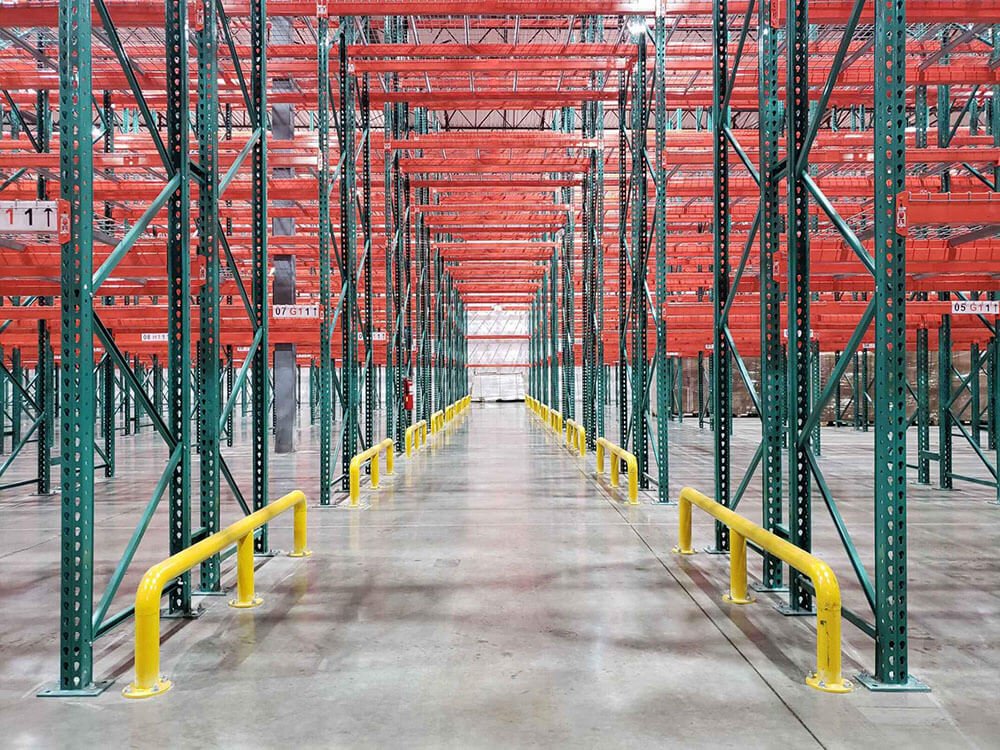

Selective Pallet Racking

Also known as single-deep racking, this is the most common type of pallet storage system due to its economical cost and wide selection of upright heights and beam sizes for custom configuration. It allows for access to 100% of the loads, making each pallet in the storage highly visible and easy to handle.

Selective pallet racking systems are available in different price ranges, from as low as $30 per rack to as high as $130 per rack. However, the typical cost ranges from $50 to $80 per pallet position.

Double-Deep Pallet Racking

This system is an adaptation of the selective pallet racking type, modified to increase storage density by using two rows deep for racking storage (instead of one row in selective racks). However, it requires more expensive loading and unloading equipment and reduces selectivity to 50%.

The normal cost for double-deep pallet racks varies from $80 to $200 per pallet position.

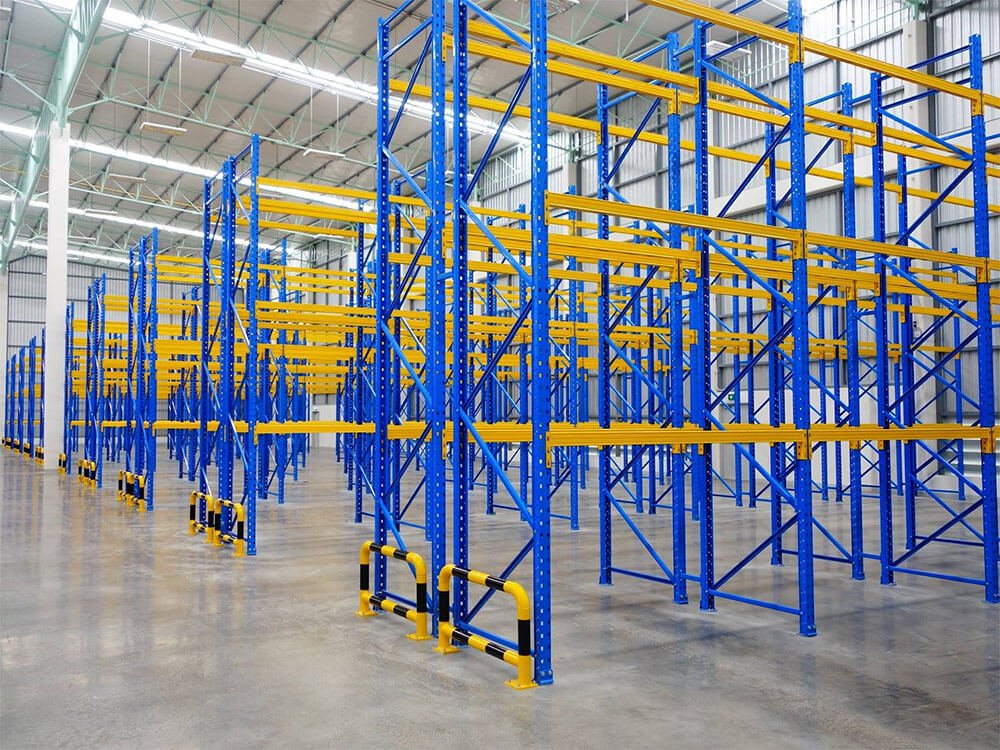

Drive-In Pallet Racking

This special racking system allows forklifts to drive directly into the rack to load and unload pallets. It is ideal for storing large quantities of similar products and facilitates high storage density.

To have drive-in pallet racking functional in your warehouse, you will need to invest about $30 to $70 per pallet position. Some models with a higher number of depths will be more costly, reaching up to $140 per pallet position.

Pallet Flow Racking

Pallet flow racking, or gravity flow racking, is a storage option that utilizes the FIFO (first-in, first-out) loading system, making it ideal for perishable goods and high-volume work with low SKU counts.

The cost of this storage system is typically higher due to its added complexity in installation and function. Expect to pay about $300 to $500 for each pallet rack of this type.

Push-Back Pallet Racking

This racking system allows pallets to be stored up to six deep on either side of an aisle, giving you a higher storage density than selective and drive-in racks. The two most popular variations of push-back racks include one with rollers and another with shuttles.

The more depths you select for this pallet racking type, the more expensive it will be. However, pushback racks’ price often ranges from $150 per rack (for 2-pallet deep) to over $270 per rack (for 5-pallet deep).

Investing In Pallet Racking Systems: Is The High Cost Worth It?

No one can dispute how vital pallet racking systems are to optimizing storage space and improving warehouse efficiency. However, they come with a relatively high upfront capital, which can be intimidating for some businesses. In this part, let’s discover if this investment decision is worth it by looking at a few aspects below:

- Considering long-term benefits: Despite the hefty initial investment, pallet racking solutions can save you a lot in the long run. By utilizing vertical space wisely, your warehouse can stock more goods without extending the floor size. Compared with facility expansion, investing in pallet racks is more affordable.

- Improving workplace productivity: By making storage more organized, pallet racking systems boost your warehouse efficiency. Your staff can spend less time accessing and retrieving the items. Thus, productivity rises, orders are filled more quickly, and profits grow, which justifies the upfront cost of pallet racks.

- Protecting goods better: Improper handling or stacking in traditional storage procedures might cause product damage. Suitable pallet racking types can help you avoid just that by shielding items from potential harm. This ensures goods are always ready for fulfilling orders and thus enhances your profits.

Conclusion

To maximize storage capacity and best utilize warehouse space, having the right type of pallet racking is crucial. Besides considering your storage demands, you must also be aware of the pallet racking cost in order to make smart choices.

There are a plethora of options available on the market, each of which has a different price tag. These prices are affected by many variables, including weight capacity, height, type, and your purchase timing. Therefore, estimating pallet racking costs is no easy task.

Fortunately, this article has analyzed all aforementioned factors in detail, enabling you to project the cost more easily and accurately. It also displays price estimations for some popular pallet racking types. Hopefully, the information herein is helpful when you are planning to install pallet racks in your warehouse.