View all Lracking warehousing equipment products

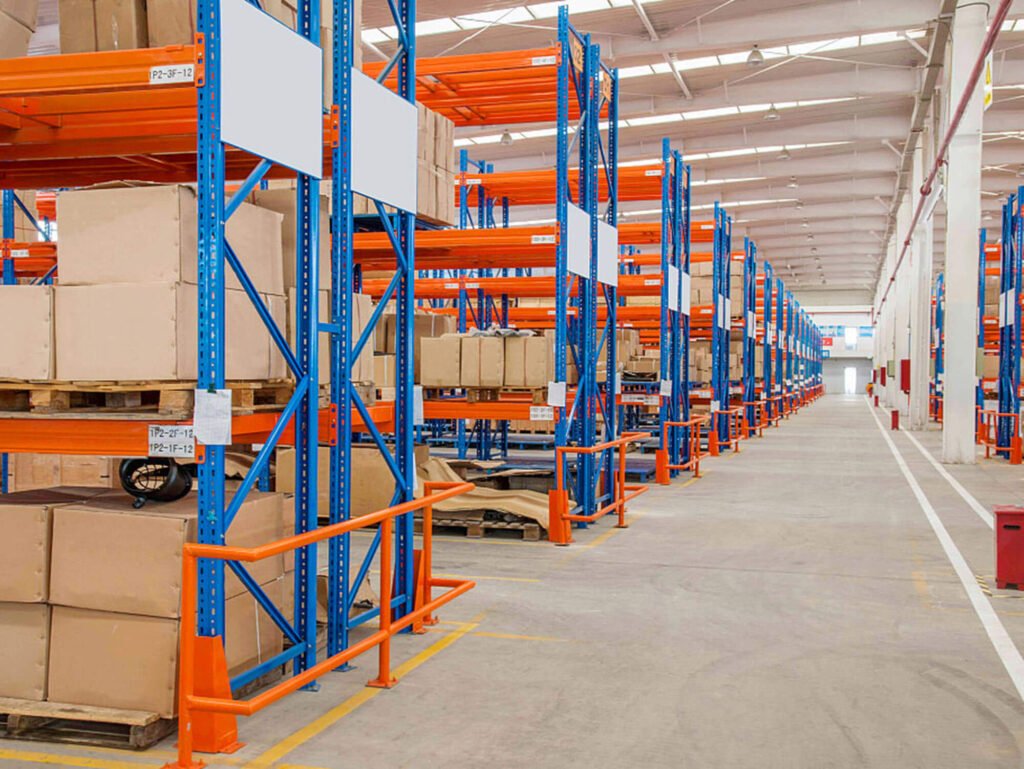

Industrial pallet racking is a racking system used in warehouses and industrial facilities to store and organize products and materials on pallets.

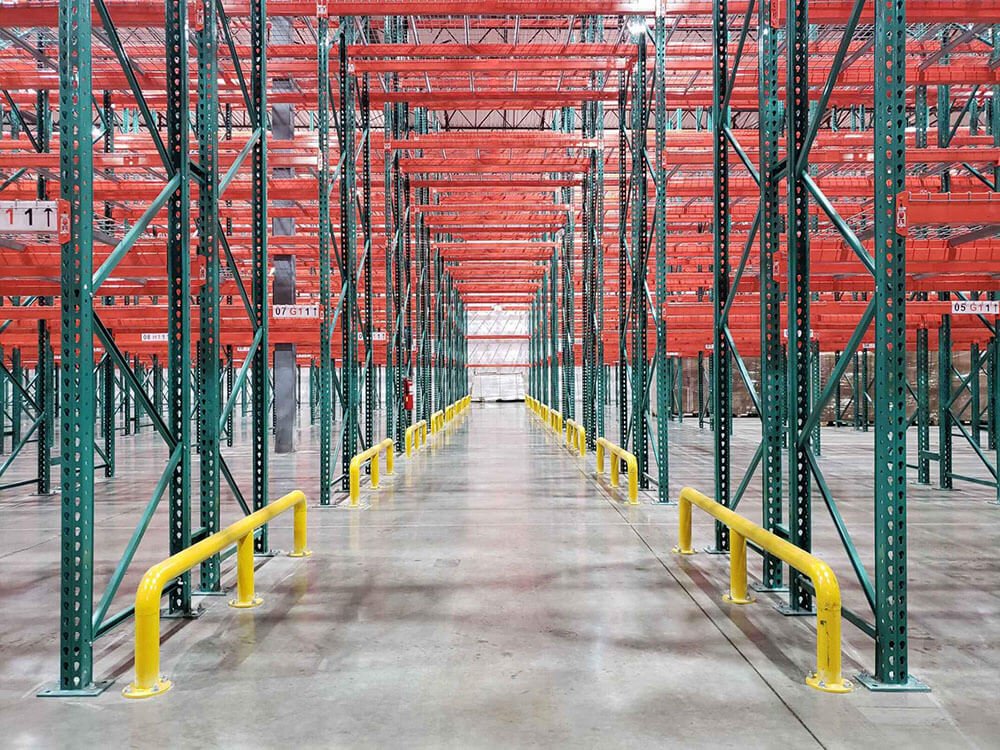

Teardrop pallet racking is named for the inverted teardrop shaped holes in its upright frame. The beams have round pins and the racking uprights are connected to the beams by pallet rack safety clips.

Drive-in pallet racking is a high-density storage solution that allows forklifts to drive inside the racking system to store and pick up pallets, hence the name drive-in racking.

Shuttle pallet racking is a high-density storage system that utilizes automated shuttles to move pallets within the racking, reducing the need for forklifts and increasing storage capacity.

Very narrow aisle pallet racking is a high-density pallet storage system that maximizes warehouse space by reducing aisle width and utilizing taller heights to store more products.

Double deep pallet racking is a LIFO storage system where two pallets can be stored by depth in the racking system. A double deep forklift is required to access the goods.

An automated storage and retrieval system is a computer-controlled racking system used to store and retrieve goods in a warehouse or distribution center.

A mobile pallet rack is a high-density storage system that uses heavy-duty wheeled carriages to move individual rows of pallet racking back and forth, creating an aisle only where it is needed.

Selective pallet racking is one of the most common rack storage systems that allows for easy access and selection of individual pallets, but it suffers from low space utilization.

Heavy-duty racking is a storage solution made of sturdy materials designed to support and organize heavy and bulky goods. Heavy-duty racking has a load capacity of 1000kg or more per level.

Light-duty racking is a storage system for storing lightweight items that can be easily loaded onto the shelves by hand. Light-duty racking usually has a load capacity of 100 to 500kg per level.

Medium-duty racking is a versatile and practical storage solution designed to hold materials and equipment in an organized manner while taking up minimal floor space. Medium-duty racking typically has a load capacity of 500 to 1000kg.

Cantilever racking is a type of storage system that utilizes cantilevered arms to support items, allowing for easy access and storage of long and bulky items such as pipes, lumber, and furniture.

Mould racking is a storage system specially designed for storing various production moulds such as die-casting moulds, hardware moulds, injection moulds, etc. Usually, cranes are used to access the moulds.

Stack rack is a kind of equipment for handling and storing goods derived from pallets, which usually can be stacked in 3 to 5 layers. Its structure is simple, low cost and easy to use, it is an indispensable equipment for storage and transportation of goods.

Mezzanine floors are raised platforms installed between the ground floor and ceiling of a building to create additional floor space. Usually, there is only one floor level and the floor loading is usually no more than 500kg per square meter.

Mezzanine racking is a warehouse storage solution which is a multi-story mezzanine built up with racking between the main floor and the ceiling, with an aisle in the middle of the racking, usually requiring manual access to the goods by hand.

H-beam mezzanine is a type of industrial mezzanine with H-beams as the main support structure, designed to create additional floor space in industrial warehouses. It has a high load capacity of up to 1000-3000kg per square meter.

A roll container is a movable, collapsible unit used for material handling, usually designed with two directional wheels and two universal wheels for ease of use, and is primarily used in warehouses and distribution centers to transport and store goods.

Wire mesh container, also known as folding wire container, is a very important handling tool in storage and transportation, it has a fixed capacity, neatly stacked, and can be folded and stored when not in use, which is very space-saving.

A platform trolley is a simple yet effective form of equipment used to transport goods and materials from one place to another, typically in industrial or commercial settings, and it features a flat platform that can be easily pushed or pulled on wheels.